-

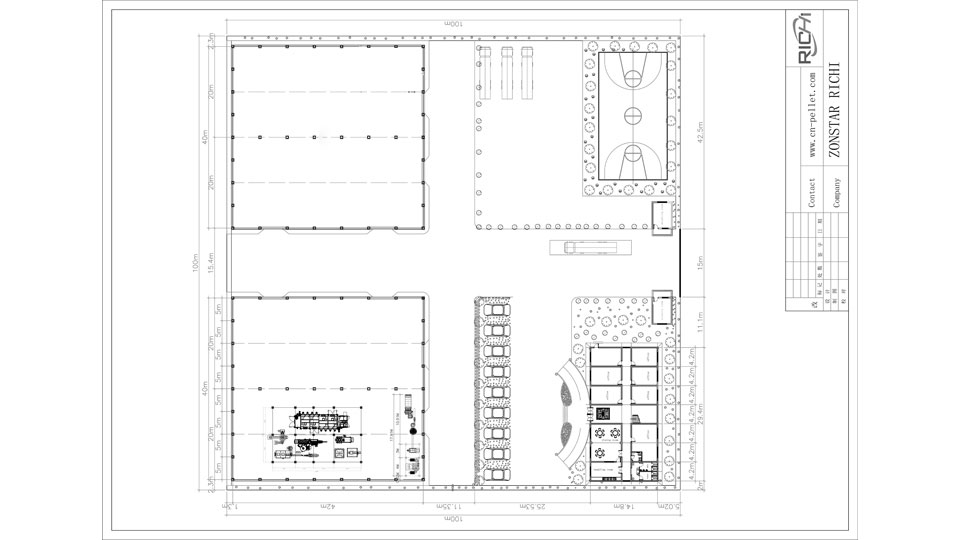

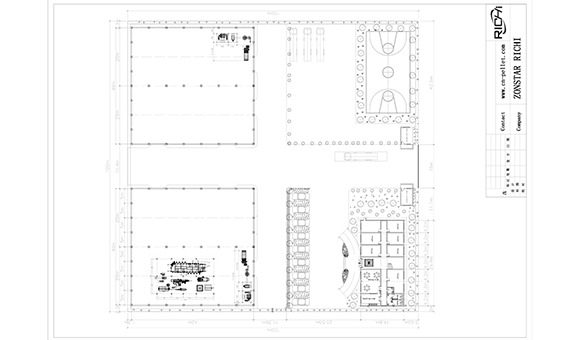

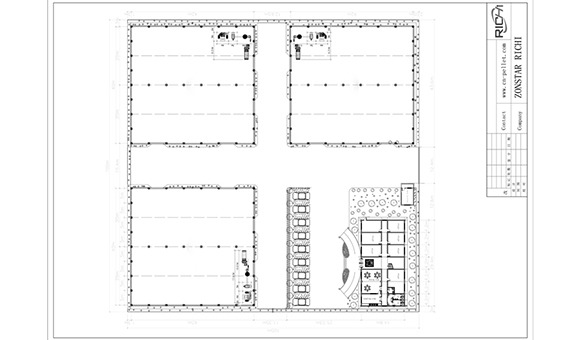

1Biomass raw materials preparation

-

2Raw materials - wood chipping system

-

3Raw materials - wood crushing system

-

4Raw materials - wood drying system

-

5Wood pellet making machine

-

6Wood pellet cooling machine

-

7Wood pellet screening machine

-

8Automatic pellet packing machine

This is the first step which includes sieving, storage and protection. Sieving is done to remove unwanted materials like stone, metal, etc. The feedstock should be stored in such a manner that it is away from impurities and moisture. In cases where there are different types of raw materials, a blending process is used to achieve consistency.

If the biomass raw materials are quite large, such as tree trunks, branches, a heavy-duty wood chipper is needed. It is also suitable for fiber stalk-like materials such as bamboo, corn stalks, sorghum stalks, etc. For more different raw materials, it may be necessary to configure equipment such as straw cutter machines, debarkers, shredders, etc.

Before feeding biomass to pellet mills, the biomass should be reduced to small and proper pellets. Uniform pellet size is important for a good pellet quality and little dust content. Size reduction is done by grinding using a biomass wood hammer mill.

The moisture content in biomass can be considerably high and are usually up to 50%-60% which should be reduced to 10 to 15%. Therefore drying is a necessary step in preparing biomass wood residues for pelleting. Rotary drum dryer is the most common equipment used for this purpose.

This system is to make biomass sawdust into biomass pellets. The material is entering in the biomass pellet mill passing through the conditioner. Here other ingredients could be added, before the material goes into the pellet pressure chamber to be transformed into pellets by the ring die. Then control the length of final pellets , through adjust the distance between cutter and ring die to get the desired length of pellets.

Due to the compression generated in the die, excess heat is developed. Thus, the pellets are very soft and hot (about 70 to 90℃),not suitable for packaging, so it needs to be cooled and dried before its storage or packaging.

The forming rate of pellets is around 98% , so there are still have 2% powder in pellets, by screening, sort out all the powders from pellets. The sieved pellet go directly to the finished product warehouse, and then are weighed and packaged. The sieved powder enters the biomass pellet mill through the pipe to re-granulate.

The qualified pellets are packed into plastic bag from 10 kg to 100 kg .Then use thermoplastic sealing machine to sew, these can make the pellets dry and water-proof . To extend the biomass pellets storage time.