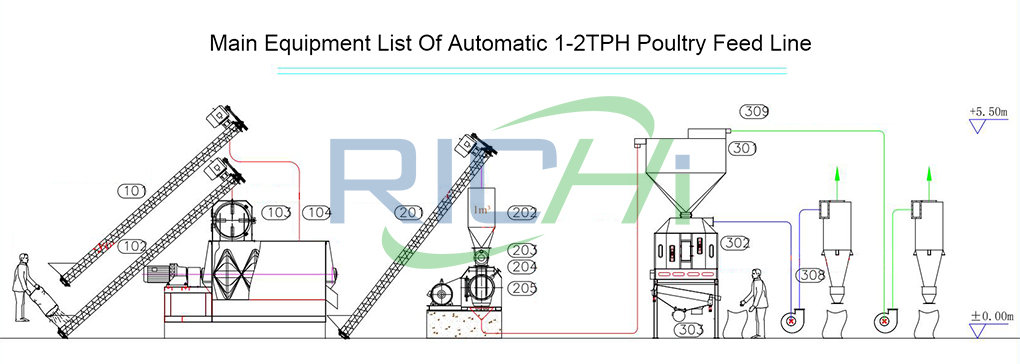

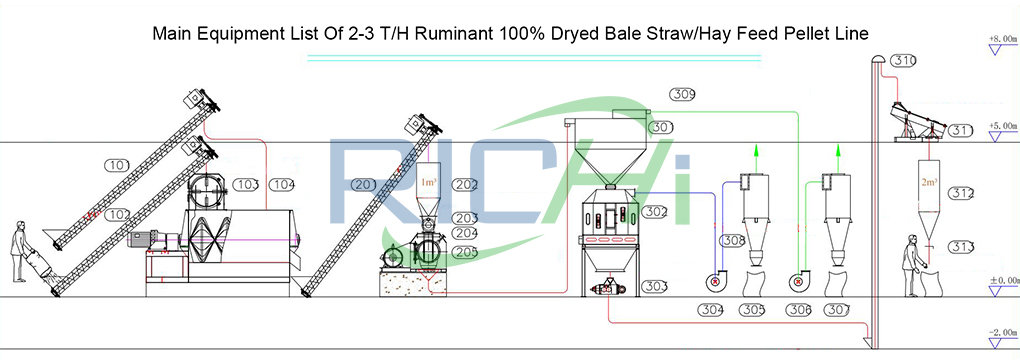

The feed mill's various raw materials are put into storage or put directly into use through specific standardized procedures, divided into bulk raw material receiving, packaged raw material receiving, liquid raw material receiving.

Clean out the impurities and iron-containing substances in the raw material, and let the clean materials enter the feed hammer mill for crushing. Its significance is to ensure the product quality and ensure the regular operation of the crusher.

The raw materials that need to be crushed enter the buffer bin after going through the cleaning section and then enter the feed grinding machine. According to the formula's requirements, the raw materials are crushed to a certain degree of fineness and then transported to the next section with wind.

According to the feed formula requirements, different raw materials are mixed with additives, oil/fat, medicines, etc. It is accurately weighed through the PLC control program, and the weighing and mixing process is completed in the shortest time.

The crushed powder materials are pelletized, and different feed pellet size can be produced by changing other ring dies. Pellet feed has comprehensive nutrition and strong stability, improving feed by animals' digestibility, reducing animal picky eating, convenient storage and transportation, and economical.

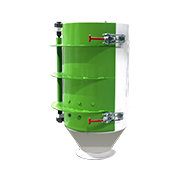

The feed pellets' temperature coming out of the animal feed mill machine is 80 degrees, and the moisture is 15-16%. It is not suitable for packaging, so it needs to enter the counter-flow cooler to cool the pellet feed to room temperature slowly.

Through sieving, the qualified pellets are extracted, the unqualified small pellets or powder feed is sieved out and re-granulated. The pellets whose geometric size is larger than the qualified pellet product are returned to the pellet crumbler machine for crumbling.

Our conveyors cover all feed processing sections throughout your feed plant. We can customize a conveying system using any combination of bucket elevators, screw conveyors, scraper conveyors.

Finished feed need to be packed, ready to dispatch. The packaging system offers maximum flexibility. Matching requirements in product suitability and capacity. It is suitable for pellet feed and powder feed products and can be manual or automatic bagging depends on requirement.

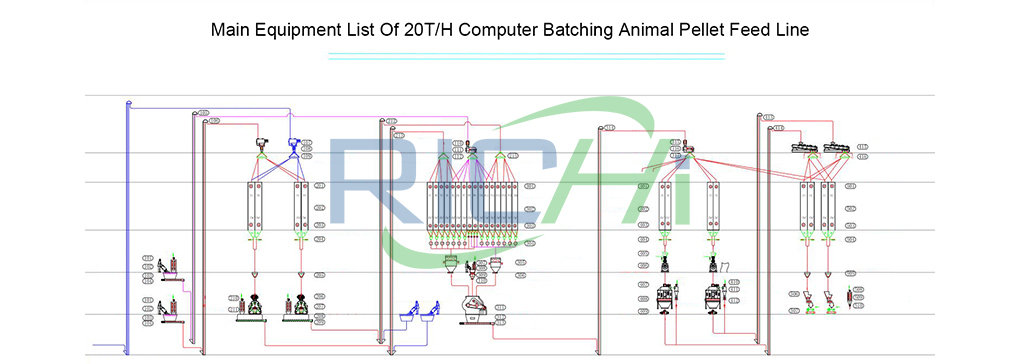

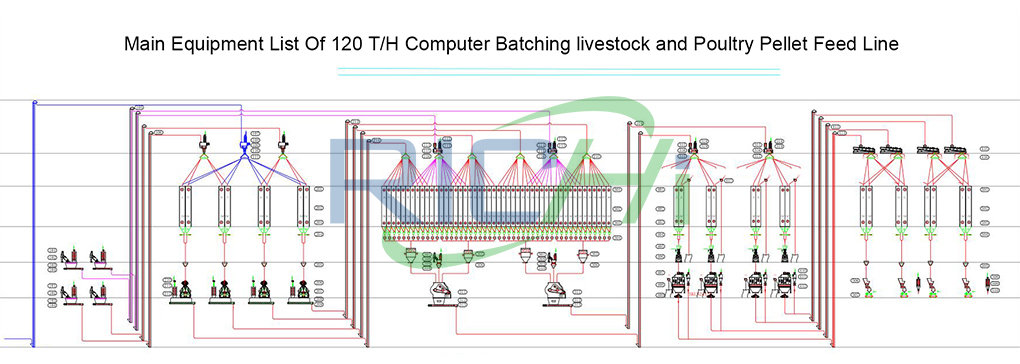

Core Animal Feed Mill Equipment

Get Price

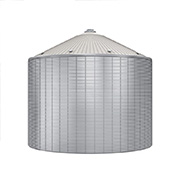

Silo System

Silo System

Silo System

Silo System

Silo System

Box Cylinder Pulse Dust Remover

Drum Powder Cleaner

Pulse Dust Collector

Drum Magnetic Separator

Pellet Cleaning Sieve

Animal Feed Hammer Mill

SFSP Fine Grain Hammer Mill

Feed Hammer Mill

Animal Feed Grinding Machine

SFSP Feed Hammer Mill

Single Roller Double Paddle Mixer

Animal Feed Mixing Machine

Stainless Steel Feed Mixer

Single Roller Double Rotary Belt Mixer

Twin-shaft Paddle Mixer