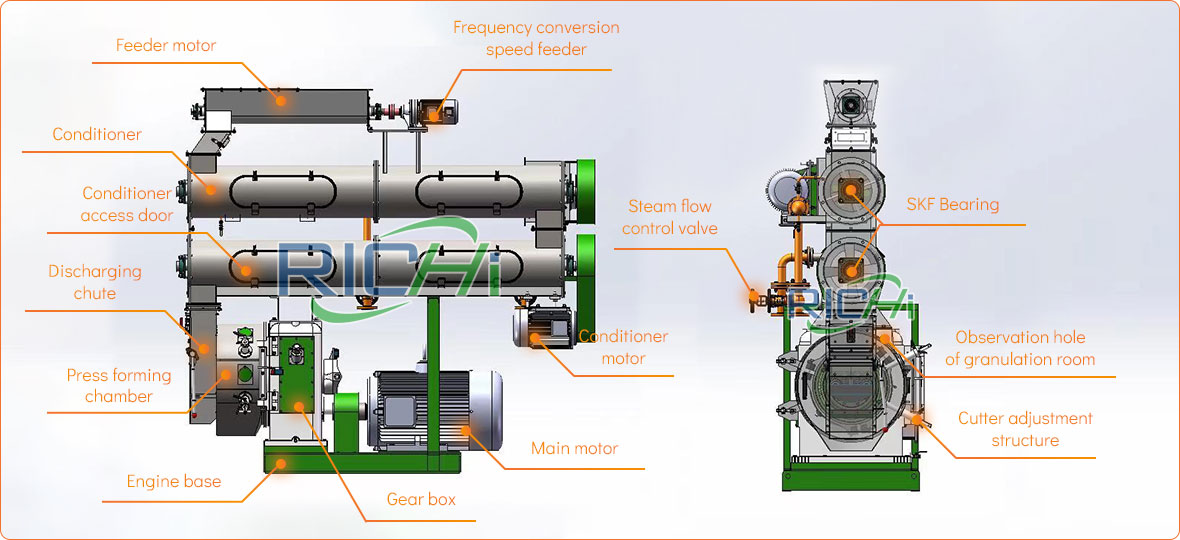

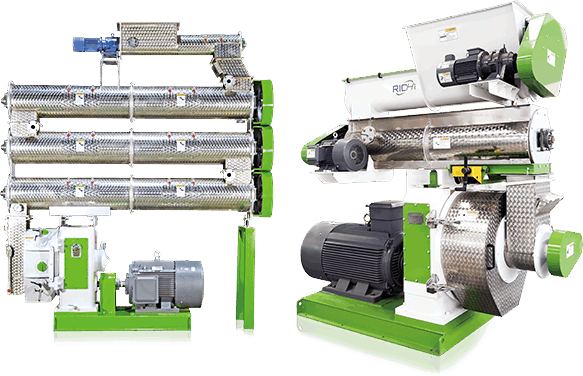

Frequency Control Feeder of Feed Pelleting Machine

Adopts the advanced variable frequency motor feeding, with overload protection devices and machines outside the nesting organization; belong to Inverter feeder (can change the feeding speed);Stainless steel material; Siemens electric motor.

Contact Us