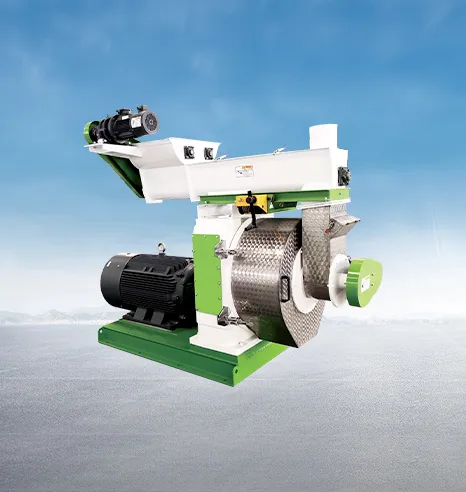

Optimized feed inlet with anti-arching configuration, supplemented by Siemens frequency conversion feeding motor, so that any wood material can be silky smooth into the pelletizing chamber, improve production efficiency and at the same time reduce the failure rate of the equipment.

Brand

RICHI

Raw Material

Wood Sawdust

Finished

Sawdust Pellets

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

|---|---|---|---|---|---|---|

| Main Motor Power(Kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch Breaker Feeder Power(Kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power(Kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished Pellets Diameter (mm) | 4~12 | 4~12 | 4~12 | 4~12 | 4~12 | 4~12 |

| Production Output (TPH) | 0.2-0.3 | 0.3-0.5 | 1.0-1.2 | 1.5-2.0 | 2.5-3.0 | 3.0-4.0 |

Technological innovation is essentially all about customer service. To make you feel the convenience of RICHI's products, technologies and solutions in the process of wood sawdust pellet production.

Feeding and conditioning systems

The frequency conversion feeding system with anti-arching improves the continuity and consistency of the raw material conveyed to a large extent. At the same time there is still a forced feeder escorting the feeder before pelletizing. This improves the yield and quality of the sawdust pellet production from the source.

Drive system

High-end Siemens industrial grade drive motor drives the drive shaft of RICHI sawdust pellet mill, which is more stable and durable than traditional belt drive. In the long run, this not only improves efficiency but also saves maintenance costs.

Structure and material

The body of the machine is made of high quality and high specification alloy steel, which is sturdy and durable, reduces resonance and runs stably. The parts that come into contact with the raw material are made of high grade stainless steel, which does not affect the raw material in any way and greatly improves corrosion resistance.

Control and Safety

Each sawdust pellet mill is equipped with an independent electric control system and safety stop function. It can not only avoid losses caused by perceived errors, but also effectively protect the pellet mill and subsequent production equipment.

Discover our streamlined buying process that makes it simple and efficient for you to get a complete sawdust pellet production plant. Every step of the way is customized for your convenience, from the initial schematic design and precise manufacturing process to secure payment options and on-site installation and commissioning. At the same time, our dedicated spare parts service ensures ongoing support and optimal machine performance, giving you peace of mind for years to come.

Solution Formulation

Equipment Manufacture

Secure Payment

Spare Parts Service

HENAN RICHI MACHINERY CO.,LTD

Henan Richi Machinery Co., Ltd was founded in 1995. After nearly thirty years of development and expansion, RICHI Machinery has grown into a modern enterprise covering an area of 60,000 square meters and integrating independent research and development, production and sales.

The products involve feed pellet machinery and engineering, biomass pellet machinery and engineering, organic fertilizer machinery and engineering, conveying equipment and engineering, steel structure engineering, silo, automation control technology and engineering, etc., and each product series has passed ISO 9001 international quality management system certification and CE certification!

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn More

What raw materials do you intend to use for pellet production?

How many tons per hour about this plant you want to build?

Where will your pellet mill plant be built?

When do you plan to start this project?

A sawdust pellet machine takes loose, dusty sawdust and compresses it into solid, high-density pellets—kind of like turning flour into pasta. These pellets are compact, uniform, and much easier to store, handle, and burn. Inside the machine, the sawdust is pushed through a steel ring die under pressure and heat. No glue or chemicals needed—just the natural lignin in the wood that binds everything together. It’s an eco-friendly way to give value to waste and turn it into biomass fuel or even animal bedding.

Absolutely—and that's why more and more businesses are jumping in. Sawdust that used to be dumped or burned can now be recycled into fuel pellets, cat litter, bedding, or even BBQ briquettes. With the right market (say, local heating suppliers or fuel retailers), you can earn good margins. One customer in Eastern Europe turned a small carpentry shop's waste into a full-time pellet business. If you’ve got the raw material and space, a sawdust pellet machine can turn “waste” into real income.

The price of a sawdust pellet mill depends on how big a machine you want. For a small machine (a few hundred kilograms per hour), it may cost $20,000 to $100,000 USD. For larger lines producing 2-5 tons per hour, it could cost $100,000 to $500,000 or more. Of course, different production program designs and equipment configurations all have different prices. Comparatively speaking, the higher the production volume, the larger the investment, but still very cost-effective compared to the long-term return. We will provide you with a transparent offer based on your needs - no surprises, no guesswork. We have helped customers in Russia and Southeast Asia start with one machine and expand as their business grows.

Great question—and here’s the exciting part. Once you make your high-density pellets, they’re super versatile:

In Europe and North America, heating fuel and BBQ pellets are popular. In Southeast Asia, many customers produce for export. We help you figure out what fits your market best.

Most dry, fine sawdust from hardwood or softwood can be used—pine, poplar, birch, beech, teak, etc. But here's the key: moisture content matters. The sawdust should be 10–15% moisture for optimal pelletizing. If it’s too wet or full of bark and big chips, it can jam the machine or make crumbly pellets. Many customers use a dryer and a hammer mill before pelletizing to get the right texture. We’ll help you test your material and recommend any prep you need.

You don’t have to start massive—we offer models for every level. Many clients begin with a 500 kg/h sawdust pellet maker and scale up after gaining some market traction. If you're running a furniture workshop, sawmill, or small joinery, that size is often perfect. For those with larger raw material volumes or contracts in place, we also offer 2TPH, 5TPH, or even full 10TPH+ production lines. We’ll help you size your system based on your budget, space, and output goals.

A full line typically includes:

Not hard at all—with some basic training, most customers are up and running in no time. The machine needs:

We provide a maintenance checklist, simple manuals, and even WhatsApp support for troubleshooting. In Russia, we trained a two-person team with no technical background to run a full 2TPH line. With a little practice, anyone can manage this machine confidently.

Yes. We’ve installed machines in over 130 countries, and we have regional partners and spare parts supply systems to support you wherever you are. Whether you're in Kenya, Vietnam, Kazakhstan, or Poland, we can ship quickly and provide remote installation guidance, or even dispatch a technician if needed. We also provide training videos, local-language guides, and real-time tech support.

Absolutely. That’s where our 30+ years of experience come in. We don’t just sell machines—we help you build a complete sawdust recycling business. That includes:

You tell us your raw materials and market goals—we’ll guide you from zero to a running, profitable operation.

If you need further information, please contact us

Note: Pellet production is a continuous and complex process, requiring many equipment to complete the production from raw materials to finished pellets. Therefore, it is suitable for commercial projects but not for personal use.

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2026