Tailored Solutions for Consistent, Nutrient-Rich Poultry Pellet Feed

RICHI Machinery specializes in delivering fully customized poultry feed production lines, engineered to enhance efficiency, reduce costs, and ensure the production of high-quality feed. Our systems provide scalable, reliable solutions designed to meet the specific nutritional needs of poultry. Explore our cutting-edge technology and comprehensive services to optimize your feed production

Highlights

Customized Solutions

Application

All kind of Poultry

Capacity

Minimum 1T/H

Price

Starts at $30,000

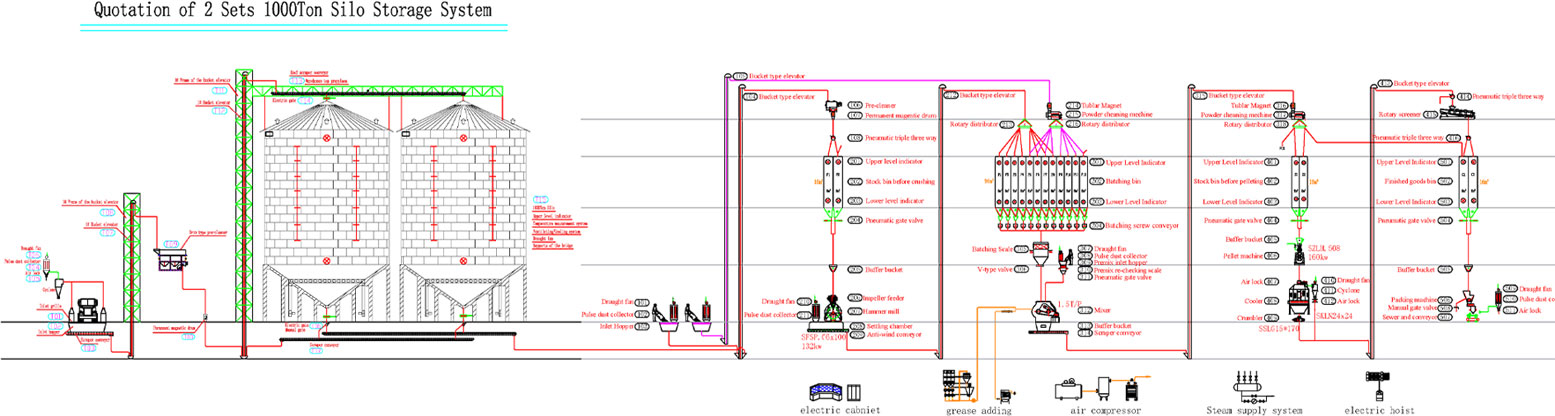

Animal Feed Pellet Production Process

Explore the equipment for each stage of poultry feed pellet production

Beginning of your successful feed pellet production business

Capacity is one of the determining factors when preparing to build a complete feed pellet production line. RlCHl Machinery will help you choose the right production output when you start your poultry feed plant construction, based on your company plan, land area, budget, market size, raw material supply, etc.

1-120T

Customized Poultry Feed Production Line On Demand

Highly Intelligent Production In All Sections

Intelligent

Depending on the output and any special needs, we will redesign the animal feed mill solution and equipment configuration.

Innovation

Fully Automatic

Standardization. Visualization. Simple and real-time monitoring.

Removes large particles and impurities from raw materials to ensure consistent production quality and cleanliness, while also effectively protecting production equipment.

Milling grains and ingredients into fine particles for use in animal feed formulations allows for better uniform mixing.

Uniformly blends various feed ingredients to ensure balanced nutrition in every batch.

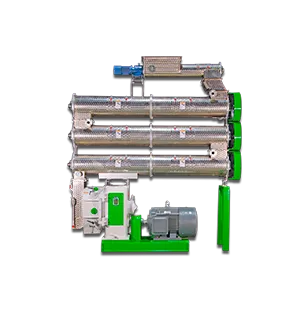

The core equipment for feed pellet production, according to different production requirements, we have different equipment configuration.

Rapidly reduces pellet temperature and moisture to enhance hardness and shelf life after pelletizing.

Specially designed to break large pellets into uniform smaller sizes, ideal for young livestock feed.

Precisely classifies feed pellets into multiple size grades through high-frequency vibration separation.

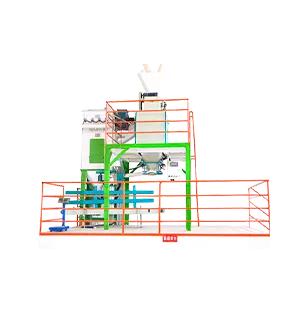

Automates accurate weighing, bagging, and sealing to streamline feed packaging and boost efficiency.

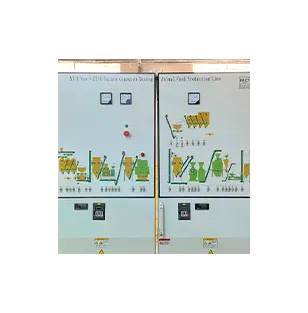

Ensures precise automation and stable operation across the entire production line with intelligent monitoring and control capabilities.

HENAN RICHI MACHINERY CO.,LTD

With decades of expertise, RICHI Machinery has successfully installed animal feed/pellet lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes poultry, ruminant and livestock feed production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, RICHI Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This state-of-the-art equipment supports a wide range of feed formulations for poultry and livestock, improving feed quality and reducing production costs. And its scalable design accommodates future expansion.

Learn More

The system is fully automated, enabling seamless operation with minimal labor and supporting sustainable agricultural practices through the use of alfalfa and other forages.

Learn More

Hardwood residues are processed into durable, high-energy biomass pellets. Designed for industrial production, the system utilizes advanced drying and pelletizing technologies to ensure efficiency and quality.

Learn More

This project is capable of producing fish and shrimp feeds, equipped with precise extrusion technology for superior feed quality. The customer emphasizes its reliability and ease of operation as the main advantages.

Learn MoreFrom the moment of your order, RICHI Machinery will provide you with all the relevant information regarding the production of feed pellets. You can also choose our turnkey project program, where we will provide all services from construction to final pellet production.

Feed Mill Planning

Equipment Production

Transportation & Installation

After Sales Service

What kind of pellet production line do you want to establish?

How many tons per hour about this line you want to build?

Where is this pellet production line going to be built?

When do you plan to start the project?

Since we are only a manufacturer of animal feed production equipment, we are not specialized in the specific proportion of each raw material in the formula. We suggest you can refer to other feed mills in your local market or discuss with animal nutrition experts to produce feed pellets that can generate market differentiation and improve market competitiveness.

Typical capacity ranges for poultry feed lines vary depending on the size of production. RICHI Machinery offers complete lines from 1-120 TPH. We also welcome the opportunity to discuss and customize your feed mill capacity.

Feed quality in a poultry feed pellet production line is ensured through several key steps:

A typical poultry feed production line includes the following equipment:

These components work together to produce high-quality poultry feed.

To choose the right production capacity for your poultry feed production line, consider the following factors:

Yes, the poultry feed production line can handle different feed formulations. It is designed to produce a variety of feed types tailored for different poultry species (chickens, turkeys, ducks) and different growth stages (starter, grower, finisher). The line allows for easy adjustments to ingredients, moisture levels, and pellet sizes, ensuring that the nutritional requirements for various poultry are met. This versatility makes it suitable for custom feed recipes based on specific dietary needs.

Moisture is controlled in the poultry feed production process primarily through conditioning and drying stages. During conditioning, steam is applied to the feed mixture to adjust moisture content, ensuring proper binding and pellet durability. After pelletizing, the feed undergoes cooling, which helps remove excess moisture while stabilizing the pellets. This control ensures that the feed has the optimal moisture level, typically around 10-12%, to prevent mold growth, maintain quality, and extend the shelf life of the pellets.

The maintenance requirements for a feed pellet production line include:

Routine maintenance helps ensure optimal performance and longevity of the equipment.

Yes, RICHI Machinery offers full installation and training services for its feed pellet production lines. The company provides expert support during the setup process, ensuring proper installation of the equipment. Additionally, they offer on-site or remote training for operators, teaching them how to efficiently run, maintain, and troubleshoot the system. This comprehensive service helps customers optimize production from the start, ensuring that their feed production line runs smoothly and effectively.

If you need further information, please contact us

Note: Pellet production is a continuous and complex process, requiring many equipment to complete the production from raw materials to finished pellets. Therefore, it is suitable for commercial projects but not for personal use.

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2026