-

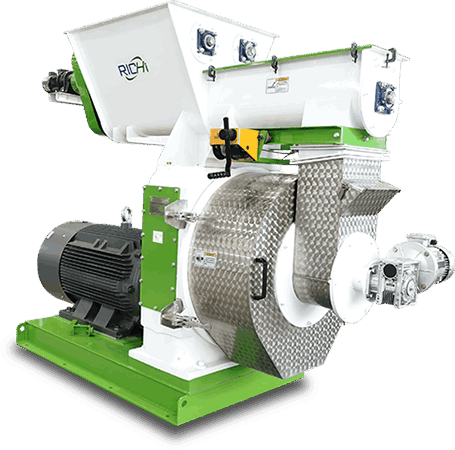

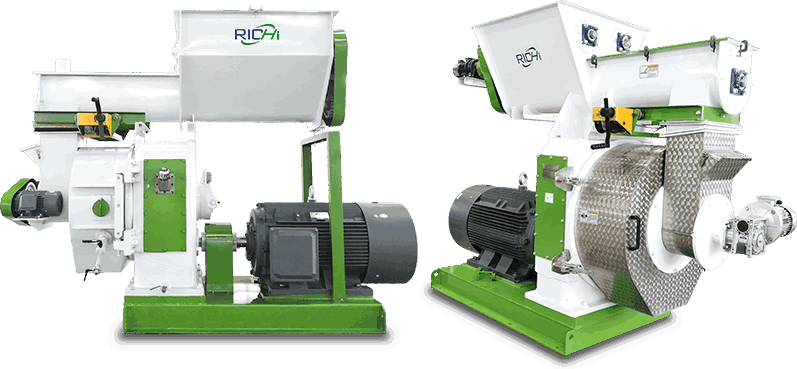

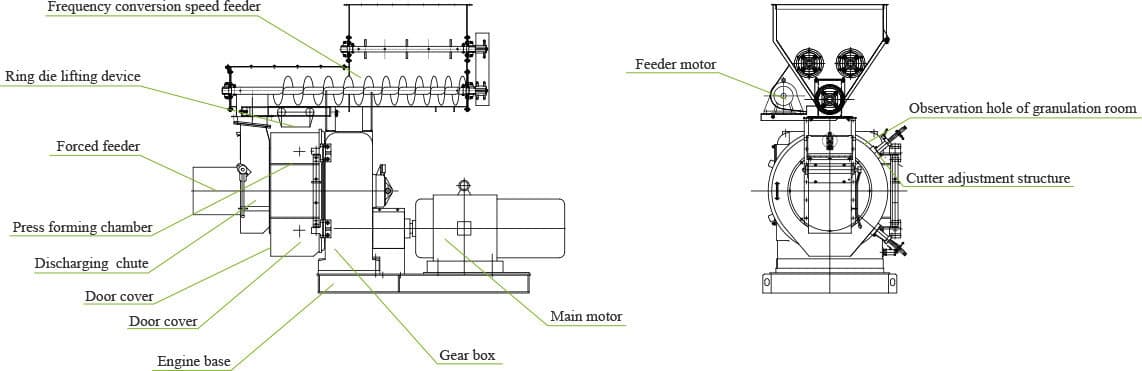

Anti-Arch Structure in Wood Pellet Making Machine

On the top of the wood pellet machine with a anti-caking bin . Inside the bin, there have two rollers for breaking the sawdust to avoid becoming cake . And the bin can keep wood pellet machine working more smoothly.

-

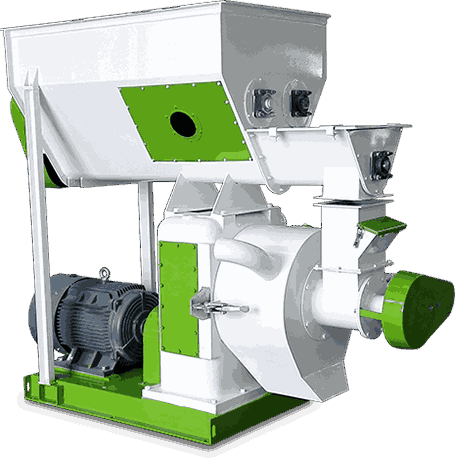

Wood Pellet Making Machine Force Feeder

Because the wood sawdust is too light , so it is difficult to enter into the wood pelleting chamber , so we add a force feeder here to improve the efficiency of the wood pelleting process.

-

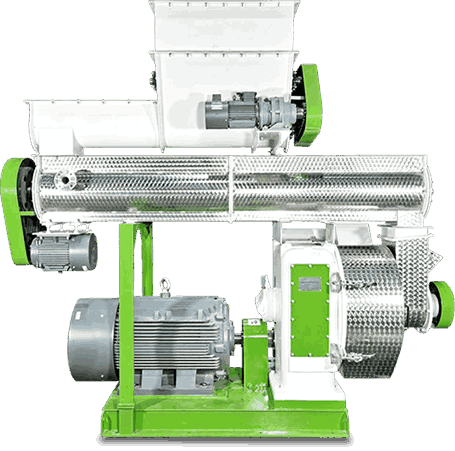

Wood Pelleting Chamber

Optimized structure of the wood pelleting chamber ensures the uniformity of the material and maximizes the working potential of the wood pellet machine. Through the pressure between ring die and rollers, to make pellets. After pelleting , the wood pellets temperature is high about 70-80℃. And have 98% qualified pellets, 2% powder.

-

Ring Die And Roller

This is the 304 stainless steel ring die, it determines the final sizes of the feed! For the ring die, it has the following data: “d”, which refers to the diameter of the ring die ; “h”, which the the depth of the hole, or you can say the thickness of the hole. (d/h=compression ratio). The bigger the ”h” is, the long time is needed to press the materials out from the ring die, more power will be required to press them, so the final wood pellets will be harder. Because the“d”is fixed.

-

Wood Pellet Machine Cutting Device

To control the length of final wood pellets , means through adjust the distance between cutter and ring die to get the different length of wood pellets.

-

Steam Discharging Outlet

When the pellet machine running , inside the pelletizing chamber ,the temperature is very high, and the moisture of sawdust enter into the pellet chamber is 15%-17% ,so it will produce a lot of steam . In order to keep the pellet machine good working, so we open a hole here, to connect with draught fan and cyclone, to exchange the steam inside the chamber and also reduce the temperature in the chamber.

-

Siemens Motors ,SKF Bearings

Siemens electric motors are synonymous with quality, innovation and the highest efficiency. The high efficiency level reduces energy consumption and directly saves costs for users. High protection level to ensure the safety and reliability for users.

Get Latest Price