This is business plan for large scale 28tph biomass wood rice husk pellet manufacturing plant,provided to customers by Richi Machinery in March 2020.

1. Project background and origin

The client company was established on August 13, 2018, and its business scope includes biomass pellet fuel processing and sales; crop straw and miscellaneous wood purchase; coal sales; providing cargo handling and handling services. (Projects that are subject to approval in accordance with the law can be operated only after being approved by relevant departments).

The company is located in Huaqiao Town, Wuhu County, Anhui Province. It leases the workshop of Wuhu Jingcheng Rice Industry Co., Ltd., covering an area of 7,500m². The company will purchase equipment and build a new biomass pellet fuel production project to form a production scale with an annual output of 70,000 tons of biomass pellet fuel. The project has obtained the Wuhu County Development and Reform Commission's "Biomass Pellet Fuel Production Project" corporate investment project notification registration form on May 12, 2020 (Fagai Notice [2020] No. 141, the project code is: 2020-340221- 42-03-019603).

2. Project construction content and scale

The main engineering of this project does not include civil construction, and directly leases idle workshops for production. The total area of the project is 7500m².

| Project category | Project name | Project content and scale |

| Structural work | Manufacturing Plant | The area is about 7500m2, including office, wood chip warehouse, rice husk storage yard, crushing and drying area, briquetting and granulating area, with biomass pellet machine, dryer and other production equipment, forming an annual output of 70,000 tons of biomass pellet fuel. |

| Auxiliary engineering | Office | Located on the west side of the plant, covering an area of about 150m2, used for daily office. |

| Storage and Transportation Engineering | Sawdust bin | Sawdust warehouse is designated on the south side of the production workshop to store raw sawdust |

| Rice Husk Yard | Delineate a rice husk storage yard on the north side of the production workshop to store raw rice husks | |

| Finished product warehouse | Build a finished product warehouse on the south side of the production workshop to store finished products | |

| Warehouse | Delimit a warehouse in the middle of the workshop for material turnover in the production process | |

| Transport | The factory relies on workers to carry it, and outside the factory relies on social transportation forces | |

| Public works | Powered by | The power is drawn from the municipal power supply network, and the annual power consumption is 100,000 kWh |

| Water supply | The water source comes from the municipal water supply pipe network, mainly domestic water, and the water consumption is 150m3/a | |

| Drain | The rain and sewage diversion system is implemented, and the domestic sewage is discharged to the surrounding ditches after being treated by the integrated sewage treatment facility | |

| Environmental Engineering | Waste gas treatment |

(1)Crushing and granulating dust(Air collecting hood + bag dust collector + 15m high exhaust pipe) (2)Dryer exhaust(Cyclone + Bag Dust Collector + 15m High Exhaust Tube) |

| Wastewater treatment | Domestic sewage is treated by integrated sewage treatment facilities and discharged to surrounding ditches | |

| Noise control | Installation of vibration damping pads on the foundation of production equipment, sound insulation of workshop | |

| Solid waste treatment |

(1)General solid waste: set up a temporary storage place for general industrial solid waste, comprehensive utilization of general solid waste (2)Domestic garbage:Set up garbage collection bins, and entrust the sanitation department to clean up after collection |

3. Product plan

| Serial number | Product name | Design capacity |

| 1 | Wood sawdust biomass pellet fuel(moisture content 6.3%) | 20,000 tons/a |

| 2 | Rice husk biomass pellet fuel (6.8% moisture content) | 50,000 tons/a |

4. The main production equipment in large automatic 28 tons per hour wood husk pellet fuel production plant project

| Serial number | Equipment name | Annual consumption (t/a) |

| 1 | Ring die biomass pelletizing machine for wood and rice husk | 4 |

| 2 | Belt conveyor | 5 |

| 3 | Biomass wood chipper machine | 1 |

| 4 | Wood crusher machine for making sawdust | 2 |

| 5 | Good quality cylindrical dryer for sawdust | 1 |

| 6 | Biomass cleaning screen | 1 |

| 7 | Biomass drying and cleaning wind net | 1 |

5. The main raw and auxiliary materials and energy consumption of the 28t/h bioenergy pellet production project for wood sawdust and rice husk pellets

(1) Consumption of main raw and auxiliary materials

| Serial number | Name | Annual consumption (t/a) |

| 1 | Wood Sawdust (40% moisture content) | 28500 |

| 2 | Rice husk (9.8% moisture content) | 51500 |

| 3 | Other Biomass(With the different seasons, the agricultural waste added is different) | 500 |

(2) Main resources and energy consumption

| Serial number | Name | Annual consumption |

| 1 | Power | 100,000 kwh |

| 2 | Water | 150m3 |

6. Public works

①Power supply

The power supply for the 28tph wood pellet project is provided by the municipal power supply network, and the project consumes 100,000 kWh of electricity annually.

②Water supply

The water used in this 28t/h wood rice husk pellet making project is mainly domestic water, and the water is municipal tap water pipe network. The water consumption of the project is 150t/a.

③Drainage

The domestic sewage is treated by the integrated sewage treatment facility and then discharged into the surrounding ditches.

7. Total number of staff and working system

Labor quota: The project has a quota of 10 people. There is no accommodation or canteen in the factory.

Working hours: 300 days a year, one shift, 8 hours a day.

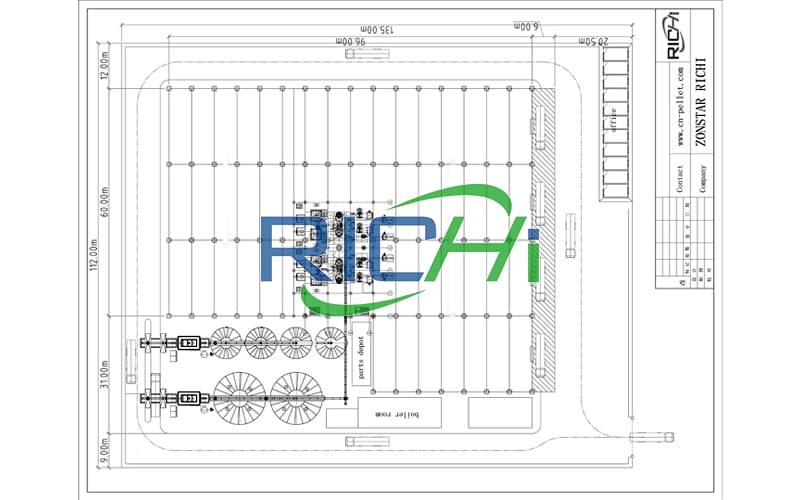

8. General layout

This large 28 ton wood rice husk pellet production line for biomass pellets project is located in Jingcheng Rice Industry, east of Jiu San Road, Huaqiao Town, Wuhu County, with a total area of 7,500 square meters.

According to the nature of the project's production and construction scale, the general layout will be arranged in accordance with the natural conditions and current situation of the site. Under the premise of satisfying industrial production land, the land use needs of material transportation, pipeline laying, environmental protection, safety and health, and fire protection have been considered in overall planning. Strive for a reasonable layout of the general map and short and smooth transportation routes. The building structures are coordinated and tidy in appearance, and the passage width is moderate, creating conditions for natural ventilation, lighting, drainage, and sanitation.

The 28t/h China complete biomass wood pellet production line project is arranged in a plane according to the production process, and the material transfer during production is smooth, which is conducive to improving production efficiency. It can be seen from the layout that the flow of people, vehicles, and freight are clear. The layout of this project is conducive to the production collaboration of various departments during the production and operation of the project and improves production efficiency. Generally speaking, the layout of this project is relatively reasonable.

9. Reasonable analysis of site selection

The local government document stated: "New projects enter the development zone. For projects under construction within 1 km of the bank of the Yangtze River and main tributaries, all those that should be relocated shall be moved to the compliant development zone in accordance with laws and regulations. The bank of the Yangtze River is 5 kilometers. All the heavy chemical projects under construction within the scope that are difficult to rectify and meet the standards and must be relocated must be moved into compliance development zones in accordance with laws and regulations.

Within 15 kilometers of the shoreline of the Yangtze River, all new industrial projects will in principle enter the development zone, of which chemical projects enter the chemical industry. The development zone or the development zone where the main industry is the chemical industry". This project belongs to the C2542 biomass compact fuel processing. It is located in the Jingcheng rice industry east of Jiu San Road, Huaqiao Town, Wuhu County. It is 34km away from the Yangtze River and 11km from the Qingyi River, the main tributary of the Yangtze River. It is in line with Wanfa [2018] No. 21 Relevant requirements in the document. In summary, the site selection of this project is reasonable and meets the planning requirements.

10. Professional good wood rice husk pellet production line manufacturing process description

Wood waste-chipping-crushing-drying-(add rice husk here) pelleting-finished product

(1) Chipping: Use a new technology agricultural wood chips crusher to perform primary processing of raw wood chips, and chip the raw materials on the original basis to meet the subsequent processing needs;

(2) Crushing: The particle size of the raw material after chipping is still large, which is not easy to granulate. Use a wood pulverizing milling machine to further crush it to make it easier to process;

(3) Drying: The moisture content of the raw wood chips is about 40%, which is not conducive to subsequent processing. Use a dryer to dry, and the drying itself only produces a small amount of water vapor.

(4) Pelleting: Use a belt conveyor to send the materials to the new design high quality biomass wood pellet making machine to be compacted and granulated to form finished pellets. Rice husk is directly made into rice husk biomass pellet fuel through this process.

11. Environmental protection measures and investment

| Category | Governance object | Environmental protection measures | Investment(USD) |

| 1 | Drying, granulating dust | Air collecting hood + bag dust collector + 15m high exhaust pipe | 10000 |

| Dryer exhaust | Cyclone dust collector + bag dust collector + 15m high exhaust tube | 20000 | |

| 3 | Domestic sewage | Integrated sewage treatment facility | 20000 |

| 4 | Noise-producing equipment | Installation of vibration damping pads on the equipment foundation and sound insulation of the workshop. | 8000 |

| 5 | General solid waste | Comprehensive utilization after collection | 2000 |

| Domestic garbage | After collection, entrust the sanitation department to clean up and handle | 2000 | |

| Total investoment: 62000USD | |||

12. Environmental impact assessment

(1) Exhaust gas

Crushing, briquetting and granulating dust is equipped with air collecting hood + bag filter + 15m high exhaust cylinder; the dryer is equipped with cyclone dust collector + bag filter + 15m high exhaust cylinder. The dust emission in the crushing and granulation section shall comply with the particulate matter emission standard in Table 2 of the New Pollution Sources in the Comprehensive Emission Standard of Air Pollutants (GB16297-1996), and the fugitive emission dust shall comply with the fugitive emission monitoring concentration limit in the standard.

The exhaust gas of the dryer meets the requirements of the Ministry of Ecology and Environment's "Notice on Issuing the "Industrial Furnace Air Pollution Comprehensive Treatment Plan"" (Huan Qiqi [2019] No. 56] for industrial furnaces that have not yet formulated industry emission standards. Key points Regional emission limits for particulate matter, sulfur dioxide, and nitrogen oxides.

(2) Wastewater

After being treated by integrated sewage treatment facilities, domestic sewage will be discharged into the surrounding ditches after reaching the first-level standard in the "Integrated Wastewater Discharge Standard" (GB8978-1996).

(3) Noise

The noise source intensity of this big capacity wood and rice husk pellet processing plant project is mainly the noise generated by the operation of production equipment, and the noise source intensity is 60-80dB(A). For high-noise equipment, noise reduction measures such as basic damping and car separation sound are taken. It is predicted that with the attenuation of the distance, the noise emission at the plant boundary of the project can meet the requirements of Class 2 standard in the "Environmental Noise Emission Standard at Industrial Enterprise Plant Boundary" (GB12348-2008), and has little impact on the surrounding acoustic environment.

(4) Solid waste

The dust collected by the dust collector is reused for production; the household garbage is collected and entrusted to the sanitation department for centralized treatment.