This is business proposal for 1.2 tph biomass wood chips and bamboo powder pellet plant project, which is provided by Richi Machinery in 2019.

1. Origin of the 1.2 ton capacity latest technology high quality wood bamboo pellet production line project

The harmful gases emitted from coal combustion are one of the sources of air pollution. At present, China has extended the coal ban from industrial boilers to civilian boilers and drying industries. Now it can be said that all coal burning places are banned. , China has promulgated policies and regulations for coal management year after year. Although "coal to electricity" and "coal to gas" are environmentally friendly, the increase in corporate costs is too high. Many companies that have just started to convert to gas are overwhelmed and close their doors or use biomass fuels instead of gas to reduce operating costs.

Environmental protection and low cost are the advantages of biomass fuel instead of gas. Biomass energy is energy with biomass as a carrier. At present, biomass used as energy mainly refers to wastes such as crop straw, forestry and wood processing. Biomass can be converted into high-efficiency solid, liquid and gas fuels, which can be used to replace non-renewable energy sources such as coal, oil, and natural gas. With the application of biomass boilers, the demand for biomass fuels in the market is also increasing. With the support of the country's vigorous efforts to control air pollution, the market demand for biomass fuels will continue to grow.

In recent years, with the development of China's economy, industrial demand has continued to increase, and the demand for biomass fuel pellets has increased year by year. Client-Ji'an Anlong Biomass Fuel Co., Ltd., based on market demand, invested 50000 US dollars and selected the site in the Forest Products Industrial Park, Henglong Town, Anfu County, Ji'an City, Jiangxi Province to build a project with an annual output of 3,000 tons of biomass pellets. The project covers an area of 1100m², with a total investment of 1 million and a total construction area of 1100m².

2. Project construction scale and composition

The main construction content of this 1.2 ton per hour wood pellet making plant project is workshops, office areas, warehouses and supporting facilities, and it is mainly engaged in the production and sales of biomass fuels.

| Name | Content | Note |

| Production workshop | Enclosed steel structure workshop, covering an area of 900m2 and building area of 900m2 | lease |

| Raw materials warehouse | Enclosed steel structure workshop, covering an area of 100m2 and building area of 100m2 | lease |

| Supply and distribution system | Park grid power supply | / |

| Water supply | Park water supply pipe network water supply / environmental protection project | / |

| Waste gas treatment measures |

Air collecting hood+bag dust collector+15m exhaust tube 1# Induced draft fan + bag filter + 20m exhaust tube 2# |

New |

| Wastewater treatment measures | The domestic sewage is treated by septic tanks... | New |

| Dust collector dust collection | Handed over to the sanitation department for unified disposal... | New |

| Noise | Noise reduction, shock absorption, wall sound insulation | New |

3. Product plan

The product of this 1.2 ton reasonable design biomass fuel wood bamboo pellet production project is mainly biomass pellets...

| Name | Designed production capacity (t) | Annual production time(hour) |

| Biomass pellets | 3000 | 2400 |

4. Main equipments needed in 1.2t/h biomass pellet making plant for wood chips and bamboo powder

| Serial number | Equipment name | Quantity |

| 1 | High efficiency wood crusher for sawdust | 1 |

| 2 | Cylindrical screen | 1 |

| 3 | Conveyors | 6 |

| 4 | Biomass wood bamboo pelleting machine | 2 |

| 5 | Air compressor | 1 |

| 6 | Biomass sawdust rotary dryer | 1 |

5. The main raw and auxiliary materials

Physical and chemical properties of raw and auxiliary materials:

| Name | Annual consumption | Source |

| Bamboo powder | 1500 | Outsourcing |

| Wood Chips | 1500 | Outsourcing |

| Other biomass materials | 240 | Outsourcing |

| Water | 150 | Outsourcing |

| Power | 20 | Outsourcing |

- Bamboo powder: Bamboo powder has a wide range of uses and is a new energy-saving and environmentally-friendly raw material. It can be used as a raw material for various products such as bamboo and plastic products, mosquito coils, leather, clothing, papermaking, electrical appliances, daily necessities, coatings, cat litter, chemicals, insulating materials, outdoor decoration materials, building materials and so on.

- Sawdust: Sawdust refers to the sawdust and shaving powder left during wood processing. It is mainly used as fuel and lightweight bone filler, or composited into man-made boards, such as medium-density board. It can also be used as a raw material for papermaking.

- Biomass fuel: refers to the burning of biomass materials as fuel, generally mainly agricultural and forestry wastes (such as straw, sawdust, bagasse, rice bran, etc.). Mainly different from fossil fuels. Biomass fuel has a large calorific value, the calorific value is about 3900-4800 kcal/kg, and the calorific value after carbonization is as high as 7000-8000 kcal/kg. Biomass fuel has high purity and does not contain other sundries that do not produce heat. Its carbon content is 75-85%, ash content is 3-6%, and water content is 1-3%. It is absolutely free of coal gangue, stones, etc., instead of heating. Heat-consuming impurities will directly reduce costs for enterprises.

Biomass fuel does not contain sulfur and phosphorus, does not corrode the boiler, and can extend the service life of the boiler, and enterprises will benefit a lot. Because biomass fuel does not contain sulfur and phosphorus, it does not produce sulfur dioxide and phosphorus pentoxide during combustion, so it does not cause acid rain, does not pollute the atmosphere, and does not pollute the environment. Biomass fuel is clean and hygienic, convenient to feed, reduces the labor intensity of workers, greatly improves the labor environment, and enterprises will reduce the cost of labor. After the biomass fuel is burned, there is very little ash and ballast, which greatly reduces the site for stacking coal and reduces the cost of ballast. The ashes from the burning of biomass fuel are high-quality organic potash fertilizers that can be recycled for profit.

6. Public and auxiliary engineering

- Water supply: The water for the project comes from the water supply pipe network of the park.

- Drainage: This project adopts rain and sewage diversion system. The rainwater is collected and discharged into the rainwater pipe network of the park. No production wastewater is produced in the project; domestic wastewater is treated by septic tanks and used for irrigation of surrounding forest land.

- Power supply: The electricity for this project is provided by the park power grid.

7. Labor quota and work system

The project has a labor force of 10 people, all of whom will go home for board and lodging. The annual production days are 300 days.

8. Industrial policy compliance

- This project is a biomass pellet production project. According to the National Reform and Development Commission Order No. 21 "Industrial Structure Adjustment Guidance Catalog (2019)", this project does not belong to the encouraged, restricted and eliminated projects. According to the "Interim Regulations on Promoting Industrial Structure Adjustment" document issued by the State Council [2005]40, this project can be regarded as permitted. Therefore, the construction of this project conforms to the current national industrial policy.

- This project does not belong to the restricted and prohibited land use projects in the "Restricted Land Project Catalog (2012 Edition)" and "Prohibited Land Project Catalog (2012 Edition)" of the Ministry of Land and Resources and the National Development and Reform Commission.

- According to the "Notice of the General Office of the People's Government of Jiangxi Province Forwarding the Implementation Opinions of the Provincial Development and Reform Commission and the Provincial Environmental Protection Bureau on Strengthening the Access Management of High Energy Consumption and High Emission Projects" (Ganfu Department Issue {2008} No. 58). The project is not a high-energy-consumption and high-emission project and complies with the industrial policy of Jiangxi Province. Therefore, the project meets the requirements of national and local industrial policies.

9. Feasibility of site selection

- Compliance analysis:

- The construction site of the ecological protection red line project is located in the Forest Products Industrial Park, Henglong Town, Anfu County, Ji'an City, Jiangxi Province. Geographical coordinates: E: 114°32'53.33"; N: 27°23'50.07", according to "Jiangxi Province "Anfu County Ecological Protection Red Line Delineation Scope Atlas", there are no ecological protection targets such as nature reserves and drinking water source protection areas around the project, which meets the requirements of ecological protection red lines.

- The ambient air in the area of the environmental quality bottom line belongs to the second-class functional area in the "Ambient Air Quality Standard" (GB3095-2012), and the environmental function of the surface water receiving water body of the Gan River belongs to the "Surface Water Environmental Quality Standard" (GB3838-2002) The middle class III functional area and regional acoustic environment belong to the second class functional area in the "Acoustic Environmental Quality Standard" (GB3096-2008); the current status of the regional environmental quality is relatively good, with corresponding environmental capacity. The wastewater, waste gas, and solid waste of this project are all properly disposed of. Noise has little impact on the surrounding area and will not impact the local environmental quality bottom line. Therefore, the construction of this project meets the environmental quality bottom line standards.

- The water used in this project comes from tap water, and the water consumption is small, which will not reach the online utilization of water resources; the electricity comes from the park's power supply; and the electricity consumption is small, it will not reach the online utilization of power resources; the project accounts for The land meets the requirements of local land use planning and will not reach the upper line of land resource utilization. In summary, the construction of this project meets the requirements of resource utilization and online.

- Environmental Negative Access List

- The projects introduced in Anfu County should strictly implement the "three simultaneous" system of construction project environmental impact assessment and environmental protection. The entry of backward production enterprises, processes and equipment that severely damage the ecological environment, endanger the lives of workers and people's health, or which are explicitly prohibited, eliminated, or restricted by the state or local government, is prohibited.

- The development and construction of Anfu County shall comply with the overall planning of Ji’an City, environmental protection planning, land use planning, economic development zone development planning and ecological protection requirements. Project introduction shall follow the requirements of "taking a new industrialization road" and encourage the introduction of technological content. High-tech, advanced technology and equipment, and a high level of clean production. This project is a biomass pellet production project. The construction of the project conforms to the industrial planning of Anfu County and meets the requirements of national and local industrial policies, and is not included in its negative list.

- Surrounding environment:

- The project construction site is located in the Forest Products Industrial Park, Henglong Town, Anfu County, Ji'an City, Jiangxi Province, with geographic coordinates E: 114°32'53.33"; N: 27°23'50.07". The current environmental air quality of the project location meets the requirements of functional zoning, the current surface water quality meets the requirements of water environment functional zoning, the current situation of regional noise meets the requirements of acoustic environment functional zoning, and the environmental capacity of the project area meets the needs of project construction. There are no cultural relics, natural reserves, and rare animals and plants within 500m of the project land. The surrounding environment is relatively simple, the soil and vegetation have strong self-purification ability, the surrounding transportation is convenient, and water and electricity supply are guaranteed. Therefore, the project site selection is more reasonable.

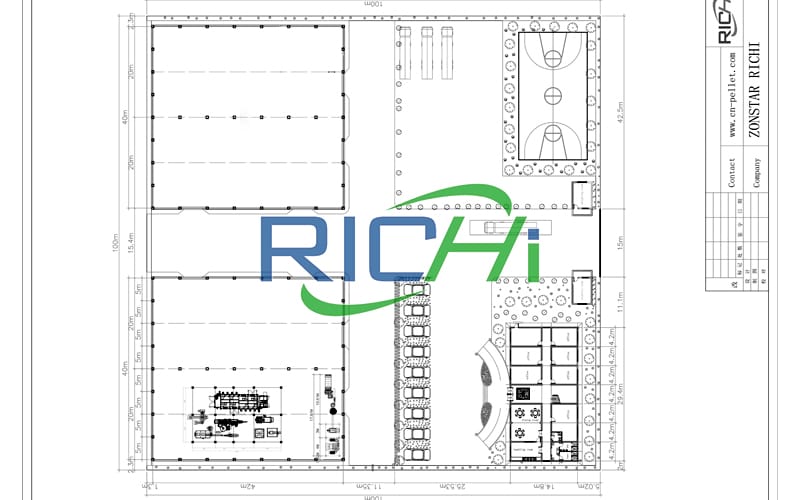

10. Reasonable layout for this 1.2t/h biomass waste pellet plant

This project meets production needs and meets the relevant requirements of fire prevention, safety and sanitation. The production workshops and sections are arranged reasonably to reduce the mutual influence between the workshop sections and facilitate production management; the production equipment is jointly and centrally arranged, and the auxiliary facilities are combined as much as possible Construction facilitates operations, improves production efficiency, and reduces product consumption; rationally organizes material transportation, shortens transportation distances, and facilitates mutual contact, which is conducive to process energy saving; while meeting production needs, priority is given to supporting and extending functions with other factories Optimize the layout and appropriately reserve room for expansion and downstream product development.

The general layout of the plant area should first meet the requirements of the production process, that is, the whole plant process should be smooth, the front and back processes should be closely connected, the transportation distance should be short and straight, and roundabout and round-trip transportation should be avoided as much as possible. The layout of the plant area is conducive to production and the physical and mental health of employees. For example, the living area and the production area should be separated, flammable and explosive products should be kept away from crowded areas, and safety precautions should be complete. The general layout of the project (including general layout and transportation organization) is conducive to energy transmission, storage, distribution, consumption and other links in the plant area. The general layout of the project is convenient for production, is conducive to improving production efficiency, and reducing process and product energy consumption. Therefore, the layout of this project is reasonable.

11. Complete 1.2 ton per hour biomass wood bamboo pellet manufacturing process flow

Purchased raw materials-screening-crushing-drying-granulating-cooling-packaging and warehousing

The raw and auxiliary materials of the project, bamboo powder and wood chips, are purchased nearby, with a moisture content of ≤20%, and the raw materials are collected and stacked in the raw material storage yard for later use.

- Screening: The raw materials bamboo powder and wood chips are screened by a drum screen, and are mainly used for the sorting of raw materials. The sieve hole of the rolling screen is about 1 cm. Large pieces of material enter the biomass materials hammer mill crusher, and small pieces of material directly enter the wood pellet maker.

- Crushing: The sieved bamboo powder and wood chips are sent to the wood chip hammer mill crusher by a belt conveyor, and the bamboo powder and wood chips are sent to the crusher by a forklift. After the impact of the blade and the knife seat, the rotating knife and the fixed knife At the same time, it is sheared and crushed. Due to the action of the rotating centrifugal force, the material automatically flows out from the outlet and enters the pit, which is sealed and sealed.

- Drying: Use a dryer to dry the crushed raw materials.

- Granulation: The crushed material is sent to the buffer bin of the wood bamboo pellet processing machine by a screw conveyor, and the crushed material is squeezed into the inner hole of the mold through a pressure roller, and the crushed material is formed by the hot extrusion of the mold. The pelletized materials is cut into cylindrical pellets at the exit of the ring die biomass wood pellet making equipment, and the whole process is physical extrusion molding without adding any binder.

- Cooling: The temperature of the molded material can be 60~80℃, and the product is cooled by a fan in the cooling chamber.

- Packing and warehousing: The finished product from the discharge port is packaged and warehousing.

12. Industrial policy compliance

- This project is a biomass pellet production project. According to the National Reform and Development Commission Order No. 21 "Industrial Structure Adjustment Guidance Catalogue (2019)", this project does not belong to the encouraged, restricted and eliminated projects. According to the "Interim Regulations on Promoting Industrial Structure Adjustment" document issued by the State Council [2005]40, this project can be regarded as permitted. Therefore, the construction of this project conforms to the current national industrial policy.

- This project does not belong to the restricted and prohibited land use projects in the "Restricted Land Project Catalog (2012 Edition)" and "Prohibited Land Project Catalog (2012 Edition)" of the Ministry of Land and Resources and the National Development and Reform Commission.

- According to the "Notice of the General Office of the People's Government of Jiangxi Province Forwarding the Implementation Opinions of the Provincial Development and Reform Commission and the Provincial Environmental Protection Bureau on Strengthening the Access Management of High Energy Consumption and High Emission Projects" (Ganfu Department {2008} No. 58). The project is not a high-energy-consumption and high-emission project and complies with the industrial policy of Jiangxi Province. Therefore, the project meets the requirements of national and local industrial policies.

13. Environmental impact analysis during operation period

- Exhaust gas:

- The air pollutants produced by this project are mainly dust and drying waste gas. The dust is discharged by 15m exhaust cylinder 1# after being processed by the air collecting hood + bag filter, and the drying waste gas is processed by the induced draft fan + bag filter. It is discharged by 20m exhaust cylinder 2#, and can meet the emission standards after treatment. Therefore, the waste gas during the operation period of this project has a relatively small impact on the environment within the assessment scope.

- Wastewater:

- No production wastewater was generated during the operation period of the project. The main water used was domestic water. After being treated in septic tanks, it will be used for irrigation of surrounding forest land after reaching the standard in Table 1 of the "Farmland Irrigation Water Quality Standard" (GB5084-2005). Slight impact on the environment. Therefore, the project sewage has little impact on the water quality and environment of the surrounding waters.

- Noise:

- In the project, measures such as sound insulation cover and foundation damping are added to each equipment, and regular maintenance is performed. The noise emission meets the "Environmental Noise Emission Standard for Industrial Enterprises and Plant Boundaries" (GB12348-2008) Class 2 zone standard. Therefore, the noise during the operation period of this project has a small impact on the environment within the assessment scope.

- Solid waste:

- The solid waste generated during the operation of this project is general solid waste and domestic waste. General solid wastes are collected by dust collectors, collected and handed over to the sanitation department for unified treatment. The domestic garbage is handed over to the sanitation department for unified disposal. Therefore, all solid wastes generated in this project are effectively disposed of and have little impact on the environment within the scope of the assessment.