Wood pelletizer is the core equipment from raw material processing to final finished pellets. RICHI Machinery always regards the development of pellet production technology and equipment quality as the purpose.

RICHI Machinery provides customers with complete pellet production solutions, converting wood chips and other biomass waste into high-yield pellet fuels, which will be used in power plants or households (heating, barbecue).

MZLH series wood pellet machine is one of the efficient, reliable and classic equipment. We adopt the most advanced pelletizing technology, combined with raw material crushing, mixing, compression and cooling processes, so as to ensure that the produced pellets meet the standards of ENplus, DINplus, CANplus.

After many times of testing and optimization, we will have more models to choose from for different raw materials and different output. Therefore, we will provide comprehensive services for the entire life cycle of the pellet plant. Contact us today for sustainable pellet production solutions.

Independent Design

Worldwide Delivery

Higher Output

Cost Savings

Turn-key Solutions

Environmentally

In order to cope with the pellet production of different kinds of materials, you can find different models of wood pelletizers from RICHI Machinery. But if you are planning to set up a new wood pellet plant with the goal of improving pellet quality and increasing pellet production, please contact RICHI Machinery immediately to obtain a complete sustainable wood pellet production plan.

Capacity: 300-800KG/H

Pellet Diameter: 6-12mm

Weight: 2500KG

Dimension: 2200*900*1300mm

Get Quote

Capacity: 500-1000KG/H

Pellet Diameter: 6-12mm

Weight: 3500KG

Dimension: 2500*1100*1600mm

Get Quote

Capacity: 1-2 T/H

Pellet Diameter: 6-12mm

Weight: 4000KG

Dimension: 2800*1150*1730mm

Get Quote

Capacity: 2-4 T/H

Pellet Diameter: 6-12mm

Weight: 4500KG

Dimension: 3000*1260*1860mm

Get Quote

Capacity: 2.5-7 T/H

Pellet Diameter: 6-12mm

Weight: 5000KG

Dimension: 3300*1500*2000mm

Get Quote

Capacity: 3-10 T/H

Pellet Diameter: 6-12mm

Weight: 5500KG

Dimension: 3500*1600*2180mm

Get Quote

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Capacity(wood sawdust,biomass) | 300-400KG/H | 500-700KG/H | 1.0-1.2 T/H | 2.0-2.5 T/H | 2.5-4 T/H | 3-4.5 T/H |

| Capacity(grass, straw, etc) | 600-800KG/H | 800-1000KG/H | 1.5-2 T/H | 3-4 T/H | 5-7 T/H | 8-10 T/H |

| Main Motor Power | 37KW | 55KW | 110KW | 160KW | 250KW | 280KW |

| Final Pellet Diameter | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

| Ring Die Material | Stainless steel | Stainless steel | Stainless steel | Stainless steel | Stainless steel | Stainless steel |

| Feeder | Anti-caking | Anti-caking | Anti-caking | Anti-caking | Anti-caking | Anti-caking |

| Forced feeding | Worm gear reducer | Worm gear reducer | Worm gear reducer | Worm gear reducer | Worm gear reducer | Worm gear reducer |

| Main Motor | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens |

| Bearing | SKF Bearings | SKF Bearings | SKF Bearings | SKF Bearings | SKF Bearings | SKF Bearings |

| Price | 15000-80000USD (Only for Wood Pelletizer) | |||||

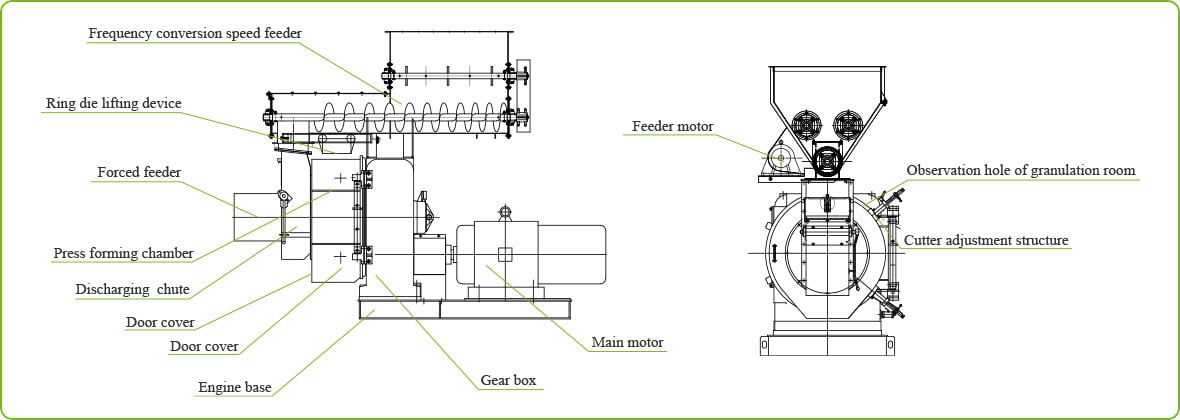

Use more efficient gear transmission; optimize the feeding system and increase the forced feeder; replace the ring die is simple and convenient; the accessories of first-line brands are more stable. Of course, these characteristics are not the only ones. After more than 27 years of production and installation experience and continuous optimization, the RICHI Machinery wood pelletizer has become synonymous with safety, efficiency and stability. We hope to provide customers with long-term, sustainable and stable products and high-quality services.

Before the pulverized material enters the granulator, a large amount of material is easy to accumulate and cause arching. However, we use methods such as spiral stirring to destroy the force balance state of the material, so the fluidity of the material can be better maintained. Improve granulation efficiency and reduce the risk of damage.

Sawdust, grass, straw and other materials are very light after being crushed, and it is inevitable that uneven feeding will occur when they enter the pellet machine. The forced feeder can significantly improve the uniformity of feeding and avoid safety accidents, so as to achieve the purpose of safety and high efficiency.

Optimized structure of the wood pelleting chamber ensures the uniformity of the material and maximizes the working potential of the wood pellet machine. Through the pressure between ring die and rollers, to make pellets. After pelleting , the wood pellets temperature is high about 70-80℃. And have 98% qualified pellets, 2% powder.

We have double press rollers and stainless steel ring dies, as well as quick release hoop systems. To cope with the production of different materials and different sizes pellets, it is possible to replace the ring die more quickly and safely, and more convenient to adjust the distance between the rollers and maintain it.

On the side of the granulation chamber, we added a quick-adjust cutter device. Customers with different requirements for particle length can adjust it freely. Convenient, fast, safe and practical. In addition, it can avoid damage to the ring die caused by improper operation.

Regardless of the size of the equipment, in order to achieve the overall stable operation and service life of the equipment, RICHI Machinery always uses international first-line brand accessories, such as Siemens motors, SKF bearings, etc. Accessories are also one of the important factors that determine the stability of the pellet machine.

Production capacity and product quality are important factors in choosing a wood pelletizer manufacturer, but design capability is even more important. After thousands of customer design schemes, RICHI Machinery's unparalleled ability to customize pellet production schemes has been achieved. Contact us for more complete wood pellet production lines.

Customize Your Wood Pellet Plant

Discuss every step of pellet production with RICHI Machinery now, we provide tailor-made solutions for the whole pelleting process, grinding, conditioning, screening and cooling. With reliable products, design solutions and service capabilities, we will become the best service provider for pellet production projects.

Drum wood chipper machine, with their large in-feed openings, lead the market and are capable of processing any waste wood product. Logs or bundles of wood with a diameter of over a meter can be reliably processed in larger wood chippers.

The enlarged feed opening and optimized distribution of the hammer blades make it more efficient when crushing forest and agricultural waste.

The new multi-combined material lifting device is adopted to overcome the "wind tunnel" phenomenon of the traditional dryer, and the thermal efficiency is higher.

The experience of our specialised teams ensure that we always work efficiently and safely, when installing new wood pellet machine and wood pellet plants.

The countercurrent cold air passes through the pellets, so that the pellets are gradually cooled from top to bottom, avoiding cracking of the pellets.

Vibrating screener is suitable for the final pellet classification and the secondary cycle pelleting process, as well as the cleaning of pellets and powders.

It is mainly used in pellet production lines. As the last step of the pelleting system, the finished product is packaged for storage and transportation.

We ensure that your pellet production is running smoothly. Always provide quality service for your pellet plant.

Our extensive experience combined with specialized testing facilities allows the engineers to accurately calculate whether your biomass can be economically pelletized. Additionally, we have been investigating the pelleting of alternative biomass species. The following are our projects in different countries, the approximate raw materials, output, and overall budget can be used as a reference.

Customize Wood Pellet Production Plant

Materials: Rice husk, Miscellaneous wood

Wood Pellet Machine: MZLH520*12 Set

Pellet Size: 6-8mm

Wood Pellet Machine Price: 550,000 USD

Project Cost: 3.6 million USD

Project Location: China

Materials: Wood Sawdust

Wood Pellet Machine: MZLH420*1 Set

Pellet Size:8mm

Wood Pellet Machine Price: 34000 USD

Project Cost: 150000 USD

Project Location: Indonesia

Materials: Wood chips

Wood Pellet Machine: MZLH520*2 Sets

Pellet Size: 6-8mm

Wood Pellet Machine Price: 90,000 USD

Project Cost: 300,000 USD

Project Location: Austria

Materials: Wood chips and wood shavings

Wood Pellet Machine: MZLH768*3 Sets

Pellet Size: 8mm

Wood Pellet Machine Price: 180,000 USD

Project Cost: 700,000 USD

Project Location: Mexico

Not only wood pellets, our wood pellet mill can also be used to process urban organic matter pellets, organic fertilizer pellets, etc. Waste by-products can be highly valuable! A wide variety of materials that are considered waste can be transformed, in most cases, into marketable recycled goods. Among many other pellet production processes, pelleting can further increase the value of these products.

The composted wastes are passed through the dryer and sterilizer, and purified from all harmful bacteria, fungi etc. Some of raw materials include: dried chicken, pig and cow manure from intensive animal production, kitchen waste, agricultural waste straw, etc.

Even at the end of their useful life, many of the components in waste ties contain valuable raw materials, and RICHI has the pellet processing technology and expertise to extract and reuse it.

Cat littler is used to bury cat feces and urine, usually in cat litter box or cat toilet. According to the different raw materials and processing technology, a feed pelletizing machine can also be used to process cat litter pellets.

PET is mainly used for fibers, and a small amount is used for films and engineering plastics. The molding process of PET includes injection molding, pelletizing, blow molding, coating, bonding, electroplating and so on.

The biomass wood pellet production line project has strong profitability, quick return on investment, and more substantial follow-up profits.

RICHI supports its customers all over the world, before, during and after delivering a machine, plant or project. If you have any questions or concerns, do please contact our support service, and a sales manager will contact you as soon as possible to give you all the support you may require.

For all inquiries fill in the form below to send us a brief message, and we will get back to you as soon as possible.