How to make cattle feed using maize corn?Energy is one of the important foundations of fattening cattle's nutrition. It is the main raw material for long enough cattle body tissues, maintaining cattle physiological functions and forming fat. The energy for fattening cattle comes from carbohydrates, fats and proteins in the feed. Due to the difference in nutrient content, feed is divided into energy feed, protein feed, roughage, silage, slag feed, bran feed, mineral feed, vitamin feed, additive feed, etc.

Energy feed is defined in "Terms of Feed Industry" (GB/10647-2008). The crude protein content in dry matter is less than 20%, the crude fiber content is less than 18%, and the dry matter metabolizable energy per kilogram of feed is more than 1.05MJ The feed ingredients become energy feed.

1.How to make cattle feed from corn maize?

How to make cattle feed using maize corn?Using corn cattle feed machine and cattle feed plants.

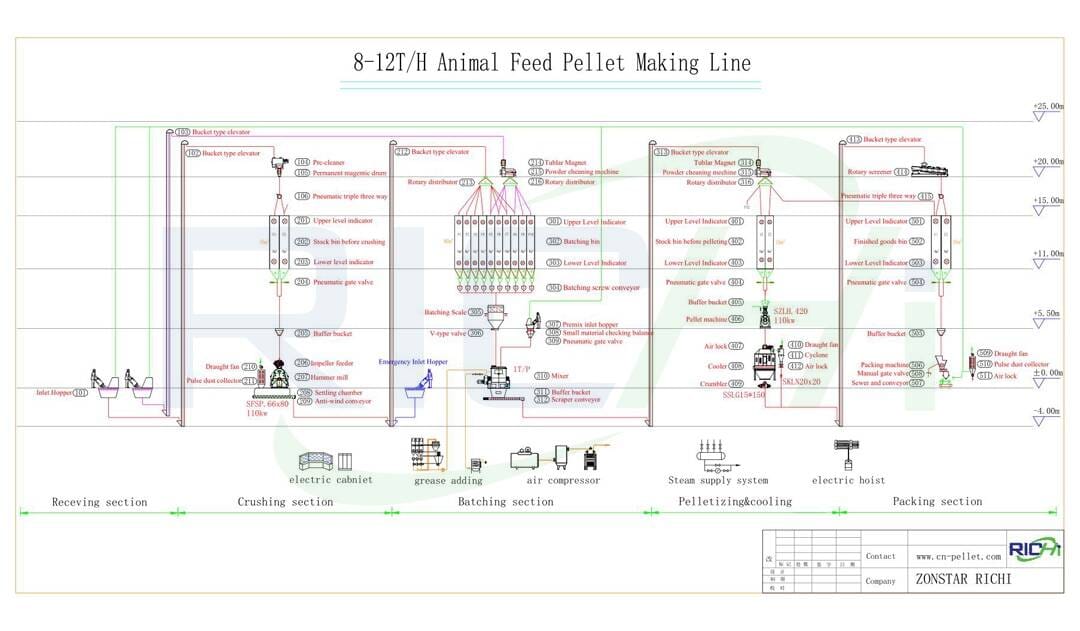

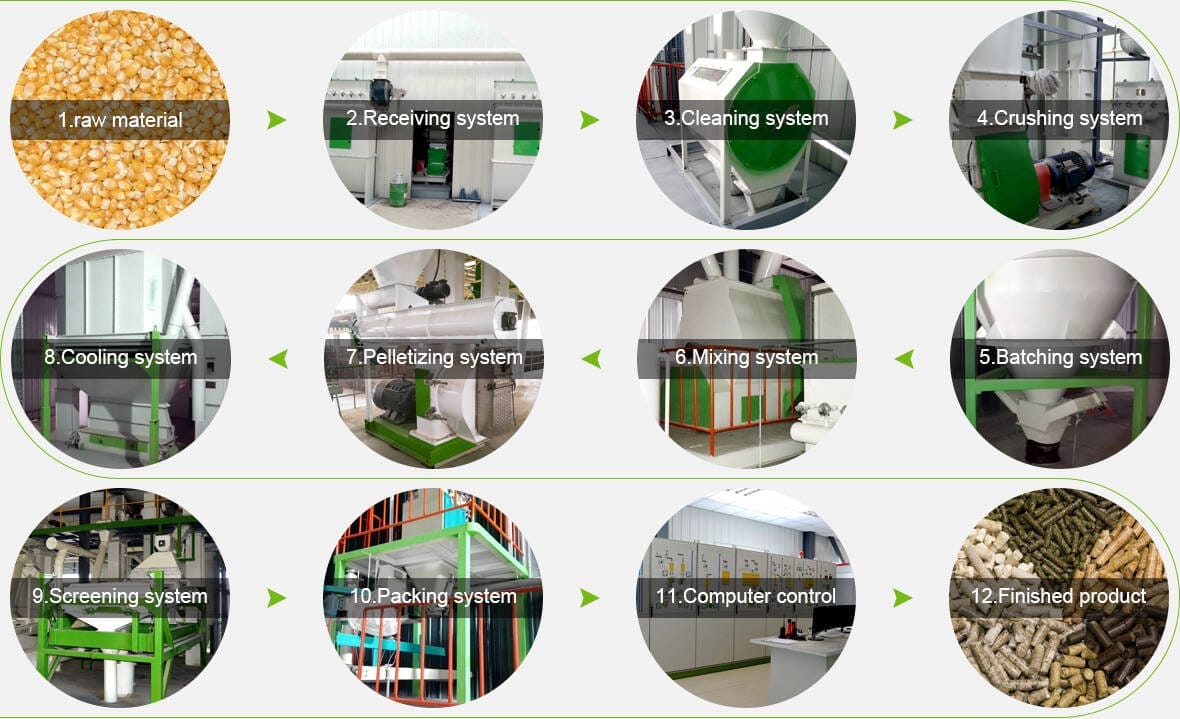

(1)Complete maize cattle feed manufacturing process

Raw material receiving--Cleaning--Grinding--Raw material pelleting--Batching--Mixing--Pelleting--Cooling--Crumbling--Liquid Adding & Coating--Packaging

(The difference in raw materials and output will directly lead to different production processes of cattle feed pellets.You can rely on RICHI to get maximum fuel efficiency at minimum maintenance cost, to receive the most productivity. )

(2)Whole set corn cattle feed making machines for cattle feed mill plants

Capacity:1-100 tons per hour.

Final Product: Pellet feed.

Pellet Size:4.0-8.0 mm.

Batching System:Manual or Automatic.

Packing System: Manual or Automatic.

①Cleaning Machine

To ensure GMP cleaning is an important aspect. Different type of cleaner used for this purpose.

②Conveying machine

All transportations like bucket elevator, screw & chain conveyor etc. for conveying RM & Finished goods.

③Grinding machine

Raw materials need to be grinded as 225 m/microne perticle size by cattle feed making hammer mill for different type of feed.

④Mixing machine

Different R/M are mixed here with additives, oil/fat, medicines, etc. Good cattle cow feed mixer ensure good quality.

⑤Pelleting machine

Produce final chicken pellet feed. A good pellet means "A complete feed" and a good animal cattle feed pellet making machine can ensure that.

⑥Cooling machine

Extruded feeds are about 70-90° C. Cattle feed cooling machine bring down it at normal temperature (+4° max).

⑦Screening machine

To ensure supply of quality and perfect size feed, screener plays a vital role. Uneven sizes screaned-out.

⑧Bagging machine

Ready cattle pellet feed need to be packed. It can be manual or automatic bagging depends on requirement.

(3)Raw materials for cattle feed making plant

Raw materials for cattle feed production in cattle feed mill plant include corn, sorghum, barley, bean cake, cotton seed cake, peanut cake, bone meal, salt, baking soda, trace elements, vitamin additives

2.Introduction of corn maize for cattle cows

Maize is an annual herbaceous plant of the genus Arboraceae. With high output and high effective energy, it is the most commonly used and the largest amount of energy feed, so it is known as the "king of feed".

Nutrition: crude protein 8%, methionine 0.15%, lysine 0.23%, high oil corn (high lysine) is currently less popularized.

There are 3 common processing methods, namely steam treatment, tableting and coarse crushing (particle size is 2.5 mm).

Don't crush too finely, so as not to affect the digestibility of roughage. Feeding cows with corn kernels, 18-33% is eliminated from feces, and tablet feeding is the best. At present, because of cost issues, cattle farms in many places use coarse crushing to process corn.

3. Characteristics of corn used as feed for fattening cattle

(1) Corn contains high energy

Comparing various feeds from the perspective of providing energy, corn is the best energy feed for fattening cattle. It is rich in starch and sugar and is a high-energy, low-protein feed.

(2) The nutrient composition of corn varies greatly

There are many varieties of corn, and the nutrient composition varies greatly due to the influence of climate, soil environment and planting level.

(3) Yellow corn contains more lutein

The pigment of yellow corn is an important source of pigment for cow and goat cream. Long-term feeding will cause yellowing of fat and reduce the quality of beef, especially in the late fattening period. The feeding amount should be controlled (for example, in some areas of Hohhot, Inner Mongolia, China, the price of butter beef is expensive due to local eating habits).

(4) Diversified shapes of corn feeding cows

The only way to use corn in China is to feed the cows in crushed powder form. According to the successful experience abroad, we can enrich the feeding form of corn to improve the feeding effect. Such as: crushed corn kernels, crushed corn kernels, crushed corn kernels, crushed corn kernels, wet corn kernels, crushed corn kernels, crushed corn kernels, chopped corn kernels, whole plant corn silage, high moisture content (26%- 30%) Corn kernel storage, etc.

(5) Corn lacks selenium in some areas

For example, in some areas of Northeast China, due to the lack of selenium in the soil, the corn lacks selenium. Therefore, when using these corns, pay attention to selenium supplementation (the supplement is 0.10 mg/kg dry matter).

(6) Corn has low saturated fatty acid content

The content of saturated fatty acids in corn is low, and long-term use in large amounts will affect the firmness of fat. Use caution when raising high-end beef cattle.

4. The best form of corn feeding cattle

(1) When feeding cattle in powder form, the diameter of the powder particles is preferably 2 mm.

(2) When feeding cattle in the form of feed pellets, 4-8mm pellets are best. (This is currently the most scientific way)

(3) Whole corn is fed to cattle. In the late fattening period, when the proportion of concentrate reaches more than 70%, whole corn has the best effect, and it is best to feed whole corn cooked.

(4) Feeding cows with wet milled corn is the best.

5.How to make cattle feed formula?

How to prepare cattle feed making pellets formula? Just see the following content:

(1) Preparation of concentrated feed

Concentrated feed includes energy feed, protein feed, mineral feed, trace elements and vitamins.

①Energy feed is mainly corn, sorghum, barley, etc., accounting for about 60%-70% of concentrated feed.

②Protein feed mainly includes bean cake, cotton seed cake, peanut cake, etc., accounting for about 20%-25% of concentrated feed. You can add 5-10% soybean cake to calf feeding and fattening young cattle. The maximum daily feeding amount of bean cake and peanut cake should not exceed 3 kg.

③Mineral feed includes bone meal, salt, baking soda, trace elements, vitamin additives, and generally accounts for 3%-5% of concentrated feed. The fattening bone meal for young cattle accounts for about 2% of the concentrated feed, and the fattening of shelf cattle accounts for 0.5%-1%. In winter, spring and autumn, the amount of salt added for the diet accounted for 0.5%-0.8% of the concentrated feed. When using distiller’s grains as the main coarse feed, baking soda should be added, which accounts for 1% of the concentrated feed. When feeding other coarse feeds to cattle, 0.3%-0.5% of the concentrated feed can be added in summer.

④Trace element and vitamin additives generally cannot be prepared by themselves. They need to be purchased from regular manufacturers and used within the specified period according to the instructions. The use of products from informal feed manufacturers is strictly prohibited.

(2) Recommended concentrate formula of common raw materials for beef cattle

①Corn-soybean meal-cottonseed meal type

Corn 63%, wheat bran 10%, soybean meal 7%, cottonseed meal 13%, baking soda 2%, fattening cattle premix 5%,

②Corn-soybean meal-flax cake type

Corn 59%, wheat bran 10%, soybean meal 8%, flax cake 16%, baking soda 2%, fattening cattle premix 5%,

③Corn-soybean meal-sunflower cake type

Corn 59%, wheat bran 10%, soybean meal 8%, sunflower cake 16%, baking soda 2%, fattening cattle premix 5%,

④Corn-cottonseed meal-rapeseed cake type

Maize 62%, wheat bran 10%, cottonseed meal 15%, rapeseed cake 6%, baking soda 2%, fattening cattle premix 5%,

⑤Corn-cottonseed meal-flax cake type

Corn 59%, wheat bran 10%, cottonseed meal 10%, flax cake 14%, baking soda 2%, fattening cattle premix 5%,

⑥Corn-cottonseed meal-sunflower cake type

Maize 60%, wheat bran 10%, cottonseed meal 13%, sunflower cake 10%, baking soda 2%, fattening cattle premix 5%,

6. Cattle feeding concentrate: How to keep the quality and freshness of corn for a long time?

As we all know, corn is an important energy feed and the main raw material of concentrated feed commonly used by cattle farmers. It is honored as the "king of feed" by the livestock industry. Next, RICHI will continue to share some corn feed quality and fresh-keeping technologies for your reference.

(1) Storage characteristics

The germ of corn occupies a large proportion, accounting for 10%-14% of the whole grain weight and 30%-35% of the whole grain volume. The body is loose and there is no poorly permeable lake powder layer on the upper part. Therefore, under relative conditions, corn has stronger respiration than other cereal feeds. Welcome to pay attention: efficient cattle breeding, WeChat public account. The fat content of corn germ is as high as about 35%, which accounts for more than 70% of the total fat of whole corn. Therefore, when the temperature is high and the humidity is high, the fat is easy to oxidize, and the acidity of the embryo increases at this time, and it is easy to be damaged and deteriorated.

The water content of corn is within the range of 14% -40%. The higher the water content, the stronger the respiration and the faster the reproduction of microorganisms and pests. When the corn moisture is below 14%, the material temperature does not exceed 25°C, or the moisture is within 13% and the temperature does not exceed 30°C, summer can be safely.

(2) Mildew of corn

The mildew of corn is closely related to water content and temperature. When the water content of corn reaches 14.3%, Aspergillus (such as Aspergillus flavus) can grow, and when the water content of corn reaches 15.6% -20.8%, Penicillium can grow. Welcome to pay attention: efficient cattle breeding, WeChat public account. The moldy process of corn is as follows: the surface of the grain is moistened (commonly known as "sweating"), and then the embryo is changed, and the mycelium of the embryo becomes green (commonly known as "dot green"), gray, and finally black, with increased musty smell , With a pungent taste, if it continues to rotten, it will lose its use value. Generally, it takes 3-4 days for the surface of the grain to wet until the hyphae appear in the embryo. If it is found in this period, it can be treated immediately and it can be saved. Otherwise, after a few days, it will reach the severe stage of fever and lose its feeding value.

(3) Pests of corn

Common pests include rice weevil, wheat moth, sawgrass, Indian corn moth and Mediterranean borer. The most serious are rice weevil and moth pests. For corn pests, a sliding sieve can be used to remove insects. With a single-layer sliding sieve of 0.5-0.6 cm and a material surface of 60 ℃, the insect removal effect can reach 97.8%. Secondly, it can be effectively prevented with low temperature storage or oxidation.

(4) Storage method

It is mainly stored in bulk. Generally, vertical silos are in bulk. The thickness of the corn stored in the vertical silo is as high as ten meters. Therefore, the moisture should be controlled below 14% and stored in a low-temperature storage or ventilated storage.

(5) Storage of corn flour

Corn flour has small voids, poor ventilation, poor thermal conductivity, and high temperature after crushing (usually 30°C-50°C), making it difficult to store. If the water content is slightly higher, it is easy to agglomerate, mold and become bitter. Therefore, the freshly crushed corn meal should be ventilated and cooled immediately. Feed mills usually use seed storage, and the ingredients are now crushed.

【More info about cattle feed】

How to make cattle feed pellet by cow feed pellet production line?

1-2 Ton per hour small size cattle feed pellet making plant machinery price

Small Scale Cattle Feed Mill Plant Machine For Making Cattle Pellet Feeds

How To Start Your High Return Low Cost Complete Cattle Feed Production Plant Business?

China Supply Easy Use 1-100TPH Cattle Feed Plant for Cattle Feed Making

China Factory Price Low Cost 5T/H Animal Cattle Feed Manufacturing Plant For Sale

How to start small capacity 1-4t/h cheap price cattle & poultry feed processing plant?

Points To Operat An Animal Poultry Cattle Feed Mill Factory With 1-10TPH Capacity

CE 1-4TPH Low Cost Beef Cow Feed Pellet Manufacturing Plant For Sale