1. How does the laying hen farm formulate the nutrition formula of the free-range laying hen feed?

In general, free-range laying hens do not need compound feed, but the nutrition can be enhanced from the following aspects while controlling the cost:

Daily feed cost components (example, China market)

| Component | Typical source | Estimated daily cost per hen | Notes |

|---|---|---|---|

| Energy | Corn kernels | ≈ ¥0.04 | Base energy source |

| Protein | Soybean meal | ≈ ¥0.03 | Balance essential amino acids |

| Vegetables / Bran | Greens, bran | ≈ ¥0.02 | Palatability & fiber |

| Calcium & Phosphorus | Stone powder, minerals | ≈ ¥0.01 | Eggshell quality |

| Total | ≈ ¥0.10 per hen per day; growth period ≈ 6 months | ||

2. It is better to feed the laying hens with chicken powder feed or chicken pellet feed

- Powder feed for layers: complete nutrition and reduced pickiness; palatability is poorer and loss from dusting can occur—avoid overly fine grind.

- Pellet feed: complete nutrition, good palatability, prevents selective feeding, labor-saving; higher processing cost and potential for over-condition if overfed. Useful in hot summer to boost intake.

At present, it is still common for layer producers to feed powder. Two common methods:

- Dry powder + free access via buckets/troughs/feeders—small nutrient gaps and labor saving.

- Wet mash, multiple times daily—good palatability but weak birds may under-consume; better to combine dry powder with free water.

(However, breeding techniques and breeds differ by country; many of our customers successfully use pellet feeds for layers.)

The difference between layer feed and broiler feed

- Different feeding standards and nutrient targets.

- Broilers mainly eat pellets; layers commonly use powder.

- Typical layer complete feed combines corn, soybean meal, wheat bran, fish meal, and shell meal per ratio.

3. The difference between complete layer chicken feed and concentrated layer chicken feed

Complete feed

- Includes protein sources (e.g., soybean meal, fish meal), energy sources (corn, rice, wheat), and additive premix (vitamins, trace elements, functional additives).

- Ready to use—no additional ingredients required.

Concentrated feed

- Most energy ingredients are removed; contains proteins + premix.

- User adds energy (e.g., corn) according to instructions.

4. Why is there a big difference in the amount of soybean meal added in the premix for laying hens on the market now?

Protein must be digested into amino acids, so amino acid balance is key. Two diets can deliver the same amino acid balance with different soybean meal levels if crystalline amino acids are used. Cost-effectiveness often favors premixes designed for lower soybean meal (e.g., 20%) with appropriate AA supplementation.

5. The amount of bran added in the chicken premix feed for laying hens

Bran has limited value to layers directly but is often used by premix makers to manipulate energy density and feed intake. Higher recommended bran can drive higher intake and cost. Changing the recommended formula (e.g., replacing bran with corn) can unbalance amino acids and micronutrients and harm performance.

6. The premix for laying hens is too expensive, how to feed the chickens?

- Premix inclusion is only ~5%—focus on bird performance and egg output. A cheaper but unbalanced premix can cost more via lost production.

7. Is the premix used for caged laying hens? What kind of layer premix is better

- Choose reputable functional feeds/premixes that enhance intake, support production, and improve egg quality with balanced micronutrients and AAs.

8. What is a good chicken feed making formula for laying hens?

Two common realities: high egg number but lower egg nutrition in some improved breeds; or high nutrition but lower lay from native/fancy breeds. Below is a sample formula for 75%–85% lay:

Sample layer diet and micronutrient specs

| Ingredient | % | Micronutrient additions (per kg of feed) |

|---|---|---|

| Maize | 58.31 | CuSO₄·5H₂O 210 mg (Cu 5 ppm); FeSO₄ 256 mg (Fe 50 ppm); ZnSO₄ 275 mg (Zn 60 ppm); MnSO₄ 220 mg (Mn 70 ppm); KI 1.32 mg (I 1 ppm); Na₂SeO₃ 0.68 mg (Se 0.2 ppm); CoCl₂ 0.823 mg; Vit A 15 mg; Vit D₃ 3.85 mg; B₁ 2.2 mg; B₂ 6.6 mg; B₆ 2.2 mg; B₁₂ 0.015 mg; Vit E 20 mg; Vit K₃ 2 mg; Vit C 20 mg; Niacin 45 mg; Folic acid 1 mg; Choline Cl 1.3 g; Biotin 0.15 mg; Flavomycin 5 mg. |

| Bran | 3.76 | |

| Cooked bean cake | 23.31 | |

| Imported fish meal | 4.00 | |

| Stone meal | 7.90 | |

| Bone meal | 2.21 | |

| Methionine | 0.15 | |

| Salt | 0.36 | |

| Calculated: ME 2.75 Mcal/kg; CP 18%; Ca 3.6%; Av.P 0.46%; Met 0.41%; Lys 0.92% | ||

9. A self-ingredient recipe for free-range laying hens

- Corn + soybean meal + bran + a quality premix. Not as tight as factory full-price feed but superior to single-grain feeding. Premixes are widely available.

10. Hens prefer to lay eggs after eating feed. Is there estrogen in the feed?

- No—balanced nutrients support reproductive performance; feeds do not rely on estrogen.

11. How to make chicken feed recipe for layers? Conventional feed formula for laying hens during the laying period

Chicken Feed Recipe 1

- Corn 60.00, bran 10.0, bean cake 10.0, locust leaf powder 2.0, fish meal 10.0, shell powder 6.9, other additives 1.0, salt 0.1.

- ME 11.34; CP 16.5; CF 2.4; Ca 3.20; P 0.71; Lys 0.91; Met 0.32; Cys 0.27. Add calcium during high lay.

Chicken Feed Recipe 2

- Corn 51.7, sorghum 5.0, barley 9.0, bean cake 15.0, locust leaf powder 5.0, fish meal 5.5, bone meal 2.0, oyster meal 6.5, salt 0.3.

- ME 11.42; CP 17.0; CF 3.0; Ca 3.42; P 0.56; Lys 0.98; Met 0.31; Cys 0.27.

Chicken Feed Recipe 3

- Corn 51.4, sorghum 5.0, barley 12.0, bean cake 12.3, locust leaf powder 5.0, fish meal 5.5, bone meal 2.5, oyster meal 6.0, salt 0.3.

- ME 11.42; CP 16.0; CF 3.0; Ca 3.27; P 0.56; Lys 0.85; Met 0.31; Cys 0.25.

Chicken Feed Recipe 4

- Corn 51.7, Sorghum 5.0, Barley 15.0, Bean Cake 9.0, Sophora Leaf Powder 5.0, Fish Meal 5.5, Bone Meal 2.5, Oyster Meal 6.0, Salt 0.3.

- ME 11.46; CP 15.0; CF 2.4; Ca 3.26; P 0.56; Lys 0.77; Met 0.30; Cys 0.24.

Chicken Feed Recipe 5

- Corn 74.60, Bean Cake 10.56, Alfalfa Meal 4.00, Fish Meal 2.50, Meat & Bone Meal 1.00, Stone Powder 5.44, Dicalcium Phosphate 1.50, Salt 0.4.

- ME 12.18; CP 14.8; CF 2.9; Ca 2.56; P 0.61; Lys 0.54; Met 0.20; Cys 0.22. High energy/low protein—raise AA and Ca as needed.

Chicken Feed Recipe 6

- Corn 55.0, mixed grains 10.5, bran 6.0, bean cake 17.0, fish meal 5.0, shell meal 3.0, stone powder 3.0, methionine 0.1, salt 0.4.

- ME 11.30; CP 17.0; CF 2.9; Ca 2.34; P 0.48; Lys 0.88; Met 0.37; Cys 0.28. Boost Ca/P.

Chicken Feed Recipe 7

- Corn 49.62, Sorghum 10.0, Bran 7.5, Bean Cake 9.0, Locust Leaf Powder 7.0, Fish Meal 6.0, Bone Meal 2.0, Stone Powder 6.5, Met 0.08, Other Additives 2.0, Salt 0.3.

- ME 11.5; CP 14.1; CF 3.2; Ca 3.23; P 0.89; Lys 0.73; Met 0.35; Cys 0.17.

Chicken Feed Recipe 8

- Corn 64.8, Sorghum 1.0, Bean Cake 18.5, Sophora Leaf Powder 0.5, Fish Meal 4.0, Bone Meal 1.5, Stone Powder 7.3, Met 0.1, Other Additives 2.0, Salt 0.3.

- ME 11.92; CP 15.3; CF 2.4; Ca 3.20; P 0.60; Lys 0.81; Met 0.38; Cys 0.20. Increase protein/Ca at peak lay.

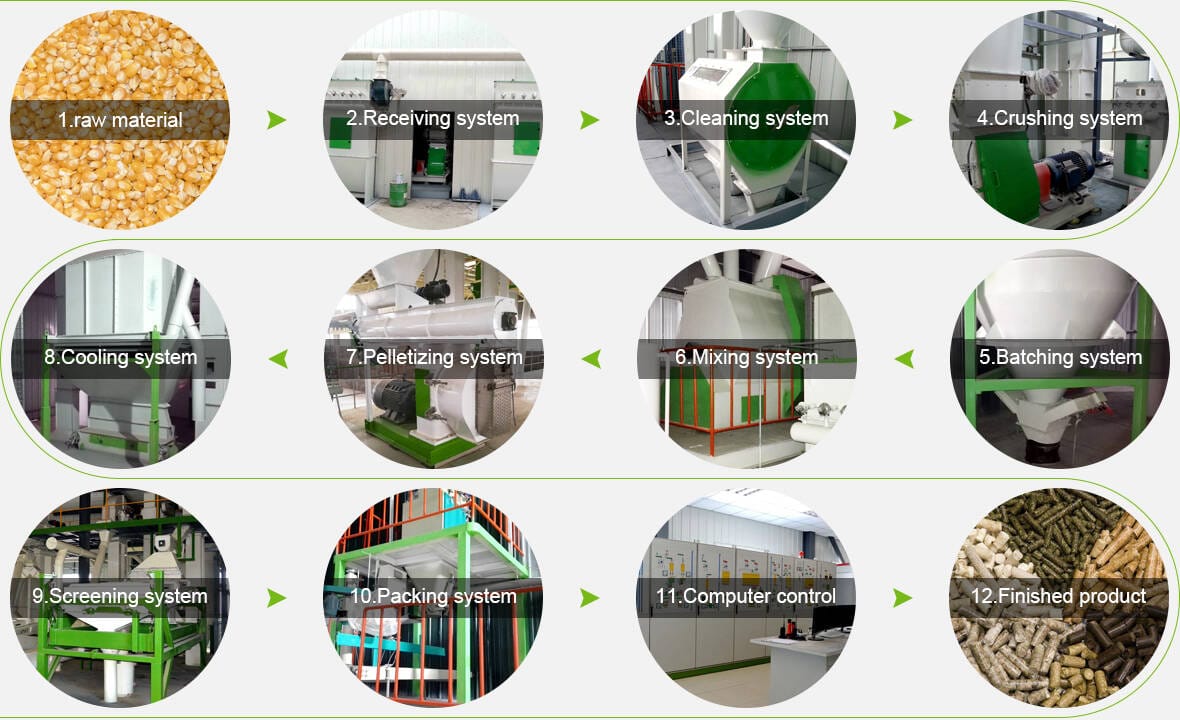

12. How to use chicken feed recipes to produce chicken feed pellets

The production of chicken feed pellets needs to start with the development of a scientific feed formulation that utilizes advanced production line technology and equipment to ensure that the feed is nutritionally balanced, palatable and easy to store. Here are a few key aspects:

Developing scientific feed formulation

- Nutritional requirements: Formulate to stage needs (brooding, finishing, egg-laying): protein, energy, vitamins, minerals, AA balance.

- Raw materials: High-quality corn, soybean meal, fish meal, wheat bran; vitamin/mineral premixes as needed.

- Ratio blending: Hit targets for CP, ME, AA, Ca/P to support health and productivity.

Raw material handling

- Crushing: Hammer mill or roller mill to improve digestibility.

- Mixing: Uniform mixing with vertical or horizontal mixer.

Pelletizing

- Moisturizing: Adjust water for proper mash moisture.

- Steam conditioning: Soften mash pre-pelletizer for better durability.

- Pelletizer: Press with a RICHI ring-die feed pellet machine; size per chicken age.

Cooling and drying

- Cooling: Counter-flow cooler to harden pellets and prevent mold.

- Drying: Target <10% moisture for storage stability.

Quality inspection and packaging

- Inspection: Check hardness, size, uniformity, nutrients.

- Packaging/storage: Seal and store dry/cool; avoid sunlight.

Importance of a modern feed pellet production line

- Efficiency: Integrated crushing–mixing–conditioning–pelletizing–cooling–packing boosts throughput and reduces labor.

- Quality: Tight process control ensures batch-to-batch consistency.

- Cost: Automation reduces labor/energy per ton and maximizes raw-material use.

- Logistics: Pellets store/transport better than mash; longer shelf life.

- Environment: Dust/noise control and efficient energy use support sustainability.

[More related info about layer chickens]

- Feed ingredient process and equipment for over 300,000 layers

- How to make chicken feed for layers in chicken poultry farm?

- How to configure the layer hen feed for small chicken farm

- What chicken pellet feed do layer hens like to eat?

- Choose the right chicken pellet making machine to process the most suitable size feed for layers

- Eat complete formula chicken feed to reduce cost of layer chicken feed mill plant

- 3 Tons per hour full automatic poultry chicken feed pellet making plant for making layer feed

- How To Make Poultry Chicken Feed Pellet For Broilers And Layers With Poultry Chicken Pellet Production Machine?

- Is it okay not to use chicken feed additives when raising layers?