"I want to open a chicken feed processing plant. What equipment do I need? How much money is needed?" Recently, a customer asked about the cost of investing in a feed plant. Today we will focus on answering.

1. What do you need to set a complete chicken feed factory?

(1) Chicken feed formula

Do you know the recipe? Do you know what type of nutritious feed the chickens eat? The most important thing to make feed is the formula. There must be a good formula to ensure the growth rate and immunity of the chicken. The following are some simple recipes we recommend, you can visit these pages to understand:

(2)animal feed pellet making line machine to make chicken feed and chicken feed plant price

① If it is concentrat feed, that is, feed that does not contain energy. Concentrat feed occupies 25-30% of the total price of compound feed. Its processing technology is almost the same as compound feed, except that the amount of crushing processing is less than compound feed. If there is no need to invest in sites, workshops, warehouses, etc., if all labor is used, and output is not required, just buying some of the simplest labor tools can still start production. But the mixer is necessary. The minimum output of the mixer is 250KG/BATCH, which may cost several thousand dollars. Assuming that 10 tons of chicken feed are produced every day, the raw materials of this 10 tons of feed also cost thousands to tens of thousands of dollars.

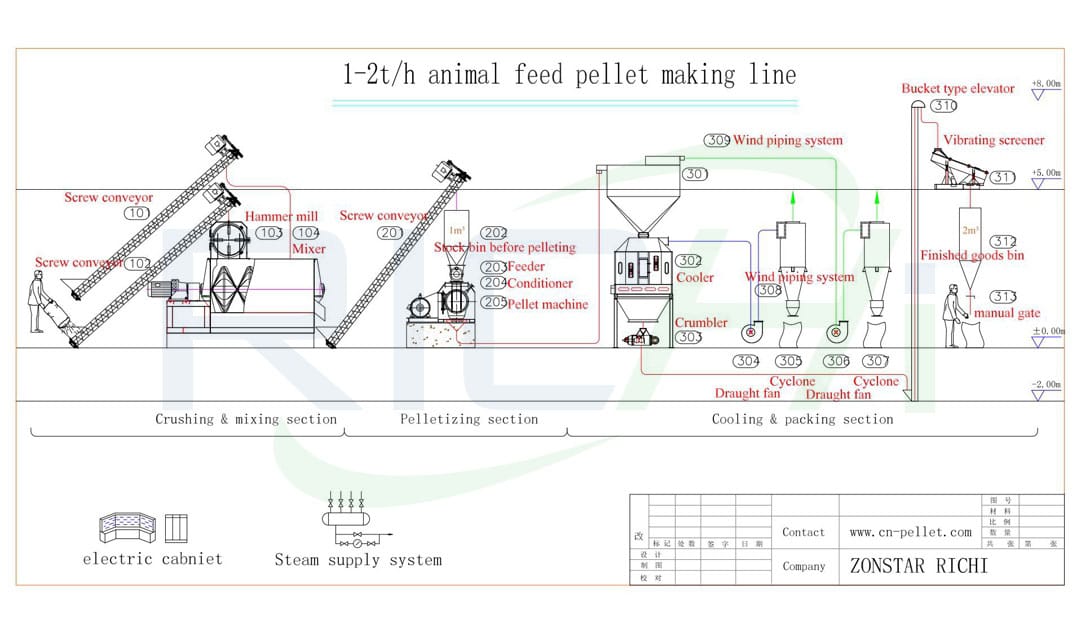

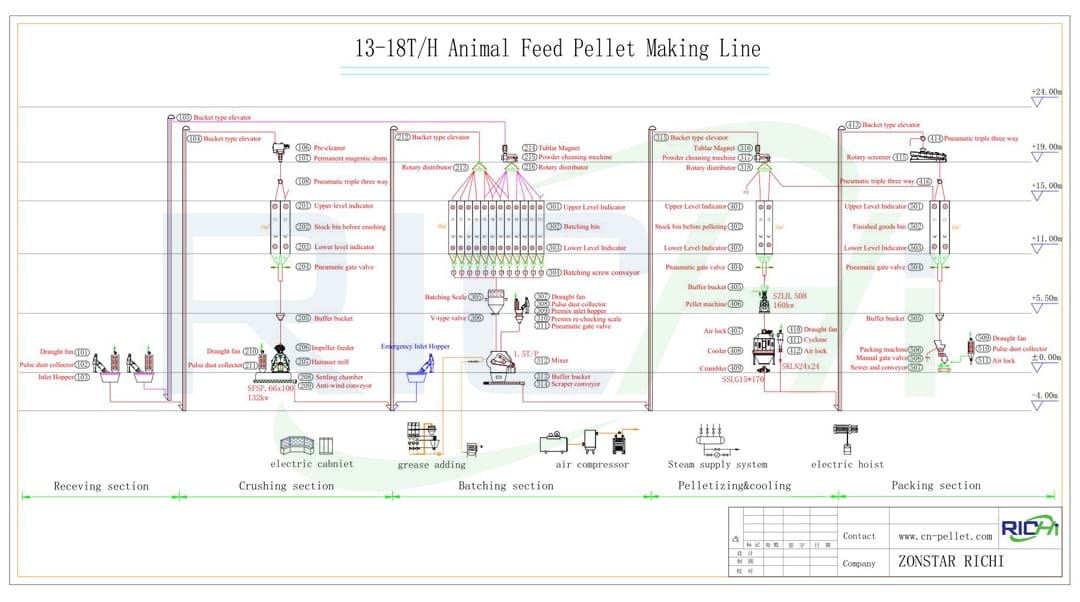

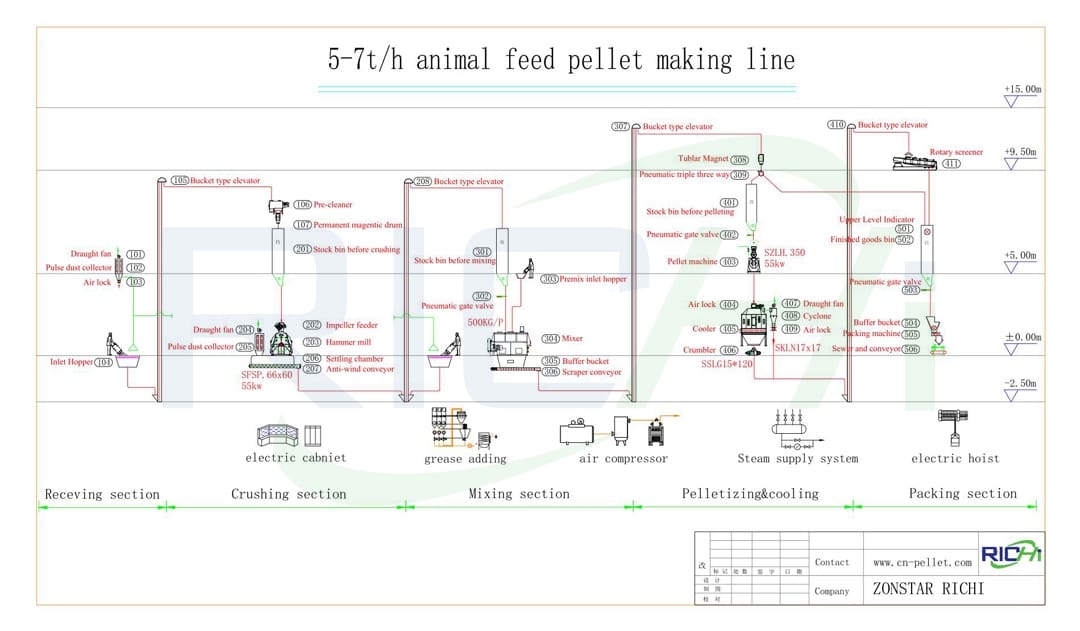

② Chicken feed is generally pelletized, which requires a pellet machine, followed by supporting equipment including mixers, grinders, grading screens, coolers, etc. Generally, cost of setting up a poultry feed plant is between tens of thousands to millions of dollars(1-100 tons/hour).

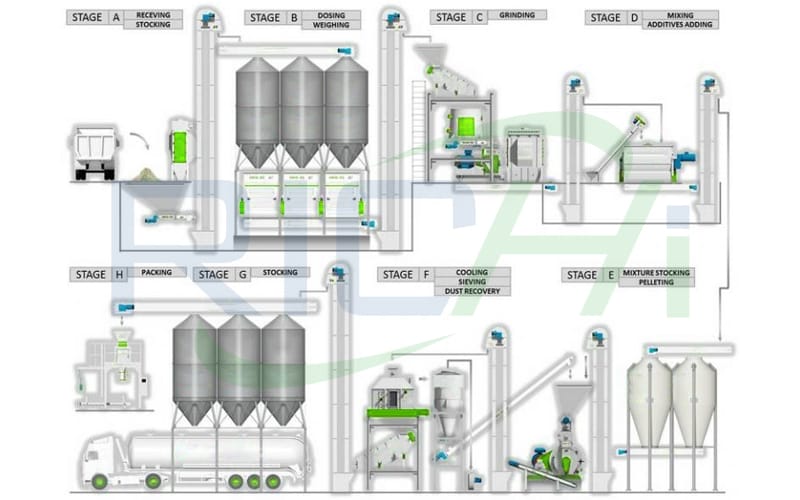

2、How to make chicken pellet feed for broilers layers?Here is the typical sections and chicken feed machine of an complete chicken feed pellet production line are:

Section A: RECEIVING AND STORAGE RAW MATERIAL

In this initial phase the supply of substances for the desired recipe is determined. Normally a reception pit is foreseen where the raw materials are delivered. Through extraction screws and elevators the substances are loaded in the storage silo.

Main Machine:SCY Series Drum Pellet Pre-Cleaner

Section B: DOSING COMPONENTS

The raw materials are conveyed by a screw to the scale where they are weighed and dosed for the creation of the requested recipe.

Main Machine:Proportioning System,Screw Conveyor

Section C: GRINDING

The material that needs to be smaller, passes through a hammer mill, in order to reach the desiderable dimension.

Main Machine:chicken feed hammer mill grinder

Section D: MIXING AND ADDING MICRO-COMPONENTS

The product is loaded in a horizontal mixer where it will be mixed and homogenized for a certain period; in this phase other micro-components can be added, like integrators or additives, necessary to the recipe.

Main Machine:chicken powder feed mixer,Intermittent Liquid Adding Machine

Section E: STORAGE FLOUR AND PELLETING

The product is now ready and could be stored for delivery or sent to the pelleting line. The material is entering in the pellet mill passing through the conditioner. Here other ingredients like steam, molasses and grease could be added, before the material goes into the pellet pressure chamber to be transformed into pellets by the die. On the outside of the holes some knives cut the pellets at the desired length.

Main Machine:poultry chicken feed pellet making machine

Section F: COOLING, SIEVING, DUST RECOVERY

After pelleting, the product is very hot, therefore it's necessary to cool the product at approximately +5°C in respect to the room temperature, in order to give it the right hardness and the best consistence to store and handle it.

In the sieving phase the product is cleaned from the dust, which is brought back into the production cycle.

Main Machine:Pulse Dust Collector,SKLN Series Counterflow Cooler,Rota-shake Sifter

Section G: STORAGE END PRODUCT

The pelleted product is conveyed to the silo for storage before delivery. It can be loaded in a truck in bulk or conveyed to the packaging line.

Section H: PACKAGING

The pelleted product is conveyed to the silo for storage before delivery. It can be delivered in bulk, loaded on trucks or packed in sacks or big-bag. The machines for packaging could be manual, semi-automatic or automatic, based on the requested production.

Main Machine:Automatic Packing Scale

3. Some poultry chicken feed pellet making line machine configuration for chicken feed plant cases

(1)Afghanistan 10T/H chicken poultry feed manufacturing plant for animal feed

Main Machines:Feed Grinder Machine*110KW,Batching Scale*1000KG/Batch,Feed Mixing Machine*1000KG/Batch,Pellet Making Machine*110KW,Cooling Machine*SKLN20*20,Pellet Crumbler*SSLG15*150,Screen and Packing Machine,Other Auxiliary Equipment.

Main Raw material:Corn, wheat,Soybean Meal, and other Grain.

Pellet Size2-6mm chicken feed pellet

The install period:40 Days

(2)Uzbekistan 15 tons per hour automatic chicken animal feed pellet making plant

Main Machines :Feed Hammer Mill*110kw,Batching Scale *1000kg/batch,Feed Mixer*1000kg/batch,Feed Pellet Machine*110KW,Cooling Machine*SKLN20*20,Crumbler Machine*SSLG15*150,Vibrating Sereen ,Packing System and other auxiliary equipment.

Main Raw material:Corn, wheat,Soybean Meal, and other Grain.

Pellet Size:2-6mm chicken feed pellet

The install period:60 Days

(3)Ethiopia 5-6T/H China supply poultry chicken broiler animal feed pellet making plant

Main Machine:feed hammer mill*37KW, feed mixer*500kg/batch and other auxiliary equipment.

Main Raw material:Corn, wheat,Soybean Meal, and other Grain.

Pellet Size:powder feed

The install period:30 Days

(4)Kenya 5T/H poultry feedstuff powder feed processing unit line

Main Machine: animal chicken feed hammer mill grinder*37 kw, animal feed mixer*1000kg/batch, cooling machine*1.5kw, screen machine*1.5kw, auto packing machine and other subsidiary equipment.

Main Raw material:Corn

Pellet Size:powder feed

The install period:30 Days

(5)Zimbabwe 3-5T/H automatic chicken feed manufacturing line

Main Machine: corn hammer mill*37kw, chicken feed mixer*500kg/batch, poultry feed compress pellet making machine*37kw, pellet cooling machine*1.5kw, pellet crumbler machine*5.5kw, screen machine*1.5kw, coal-fired boiler and other subsidiary equipment.

Main Raw materia:lCorn, wheat, and other Grain.

Pellet Size:1-2mm small baby chicken feed, 3mm,4mm,6mm chicken feed

The install period:30 Days

4. How to reduce the cost of chicken feed?

(1) Raw materials: There is an old Chinese saying that "a clever woman cannot cook without rice." The price of raw materials determines most of the cost of feed. Getting cheap and rare raw materials can significantly reduce chicken feed costs;

(2) Formula: reduce the cost of feed, but can't affect the production performance. Appropriate formula is required to formulate feed according to the available protein, amino acid and energy of feed materials;

(3) Processing: crushing particle size, mixing uniformity, and chicken feed pellet quality, all of which require high-quality chicken feed machine to ensure;

(4) Packaging: Bulk feed can save packaging costs;

(5) Storage: Purchase in large quantities when the raw materials (corn, soybean meal, etc.) are relatively cheap, and storage can also reduce costs;

(6) Transportation: Try to shorten the transportation distance and reduce transportation costs.

This article is about complete set poultry chicken animal feed pellet production line machine and poultry chicken feed manufacturing plant cost.You can directly consult Richi Machinery for more questions about"1 ton per hour poultry chicken feed pellet making plant""10t/h chicken feed pellet production machine line for poultry feed"" customized 5 ton per hour chicken animal feed processing plant""how to make organic chicken feed""corn grinder for chicken feed",Email: enquiry@cn-pellet.com,Whatsapp/Cel: +86 185 7410 3366