If you are planning to run a 20 tons per hour large capacity animal poultry chicken feed processing plant effectively and want to get some tips to make your 20t/h large chicken poultry feed pellet production factory more effecient, or your first chciken poultry feed mill is about to put into production and need some get started quickly, RICHI Machinery can always help you!

1.20TPH Animal Poultry Chicken Feed Processing Plant For Chicken Pellet Production

The primary reason to prefer chicken pellet feed is, it ensure the adequate intake of nutrients for the chick. These days, pellet feeds are the most preferred feeds for the poultry animals. While pelletized feed production, all the ingredients are grounded and mixed together in feed making machine for chicken feed to form a specific feed requirement and desired combination of nutrients.

(1)Why Choose Feed Pellets Rather Than Chicken Mash Feed?

When compared with using mash feed, the followings are some advantages of feeding your chicken with feed pellets produced by chicken animal feed pelletizer machine :

①Nutritional Composition: It consists of the proper and required proportion of the nutrients and ensures that the chicken receives the desired nutrients in adequate amount.

②Improve Performance: Ensuring balanced diet of the chicken, it improves the bird performance and lessens the wastage of feed.

③Feed Safety: As the process included high temperature, it ensures, no bacteria gets pass on to the chicken through the feed. The food is sterilized in the process.

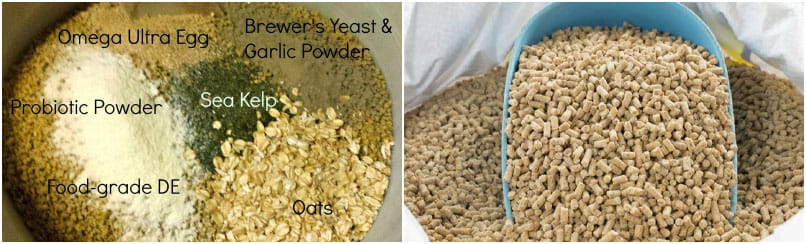

(2)Main Grain Used in Manufacturing Feed for Chickens(layers and broilers)

Grain is the main chicken feed making raw material for the ingerdients of animal feed pellets including poultry feed and cattle feed. For corn feed mill plant, corn is included as one of the ingredients in the feed. In most chicken poultry feed pellet making plant around the world, corn is a common ingredient in the chicken feed, Australia being an exception. In Australia, fewer areas have the suitable conditions to grow corn; hence the corn feeds are produced really less in Australia. Corn fed chickens tends to have a slight yellow skin color. Due to the less availability of corn, it is usually replaced by wheat and sorghum in the chicken feeds in Australia. Grains used in the chicken feeds largely depend on its local availability. Maybe you are also interested in fish feed production and the related machines.

During the growing days, chickens require proper nutrition and that's the reason there should be a proper chicken feed plans for them. Now talking about the chicken feed composition , it differs in the egg-producing chickens (layer) and meat producing chickens (broiler). The feed should contain a properly balanced nutritional ratio that will prevent slow growth and leg problems in the chicken. The feed production team needs to analyze the requirements of the chicken to prepare a proper feed for them.

Making high quality chicken feed from scratch is never an easy task. Though a proper feed is prepared from 85% -90% of cereal grains, it cannot be completely made of grains. The feed must include soybean meal, salt and concentrated vitamins and minerals as well. The different nutritional needs and the levels of growth have a direct effect on the chicken feed production.

2.Tips for Broiler Feed Pellet Processing Plant

With the increase in demand of the poultry chicken feed consumption, chicken feed production also has become a very important aspect to be focused on. Now coming to the different kind of feeds:

(1)Nutritional Requirements of Growing Broiler Chicken Feed

Requirement of any of the following nutrient is relative to the other nutrients there are few factors that need to be considered before expressing the need of a certain nutrient. Quantity of one nutrient depends on the quantity of the other. For example, the percentage of calcium, phosphorus and sodium are interdependent.

①Proteins: In the dietary requirements of chicken soyabean meal, canola meal and meat and bone meal constitute of the protein majorly. The daily crude protein intake is always kept least in the feed, for it provides an adequate amount of essential amino acids in the chicken diet.

②Amino Acids: The growth rate of the chicken depends on the percentage of Amino acid in the chicken feed. An adequate amount of amino acid is required to ensure rapid growth of the chicken and for a successful, meat chicken feed program.

③Minerals: The quantity of minerals in the feed not only depends on the requirement, but it majorly depends on the bioavailability of the mineral sources. For different sources the concentration of minerals differs. For example, there is a difference in the bioavailability of zinc in zinc sulphate and zinc oxide.

④Vitamins: It is said that the vitamin requirements of chicken reduces with the growing age. Though there's no concrete argument to prove it. Vegetable oils or animal fats are the optional ingredients to be included in the diet to provide additional energy.

(2)Composition of Typical Broiler Feed

The composition of the chicken feed varies with the varied growing stages of the chicken. The feed producers usually have a 3 stage feeding program, depending on which the feed changes as the chicken grow. It basically has the: Starter feed, Grower feed and the Finisher feed. Some of them have also introduced a withdrawal feed just before the harvest. Compared to all the other feeds, the finisher feed has the lowest composition of protein and higher in energy.

3.What can RICHI do for you?

According to customer different feed types, different output configuration can be customized. We devote ourselves to undertaking all chicken feed production line 1-20T/H and to providing more value added service to all the customers.

(1)RICHI will do these things for your 20tph chicken poultry feed mill factory:

①Determine the scale of chicken poultry feed mill plant.

②Determine the feed process and recommend chicken poultry feed machine for 20t/h chicken feed line.

③Control mode selection.

④Chicken poultry feed pellet manufacturing plant structure selection.

⑤Planning the general drawing of 20tph chicken poultry feed production plant site.

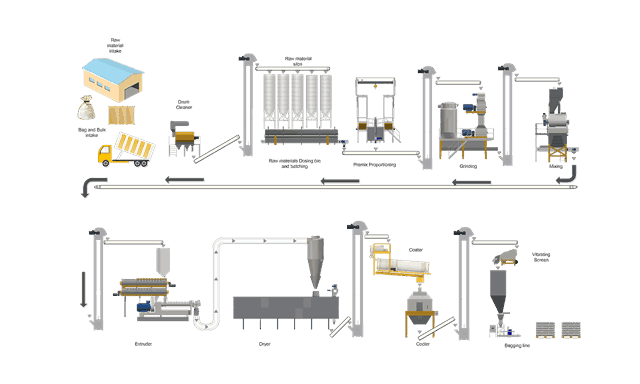

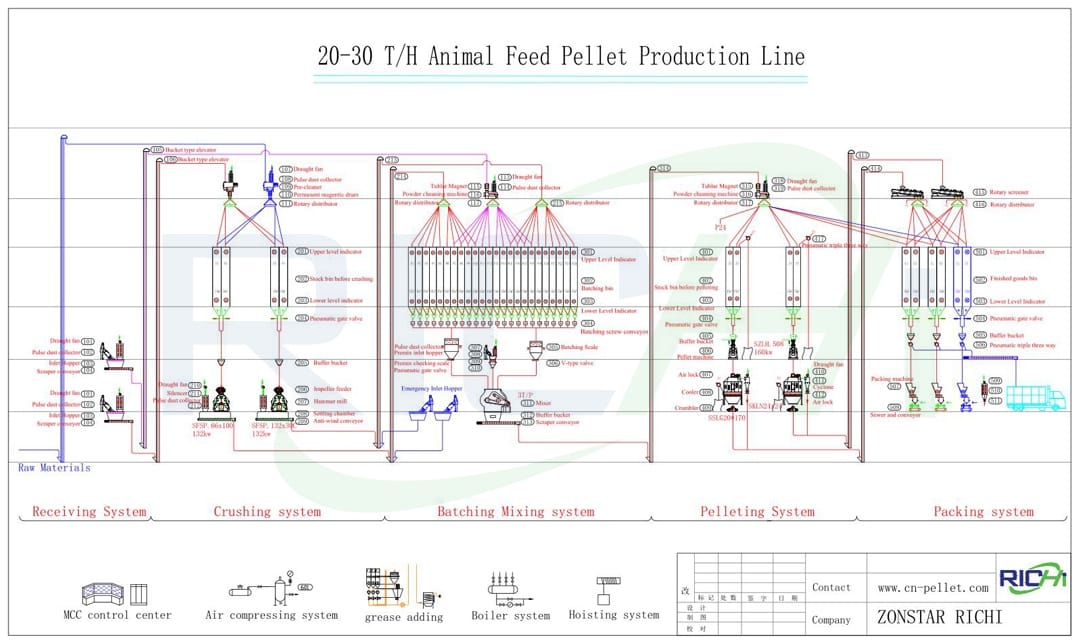

(2)20TPH complete chicken feed pellet production process:

Raw material receiving--Cleaning--Grinding--Raw material pelleting--Batching--Mixing--Pelleting--Cooling--Crumbling--Liquid Adding & Coating--Packaging

(The difference in raw materials and output will directly lead to different processing processes of pellets.You can rely on RICHI to get maximum fuel efficiency at minimum maintenance cost, to receive the most productivity. )

Capacity:20 tons per hour.

Final Product: Pellet feed.

Pellet Size:2.0-4.0 mm.

Batching System:Manual or Automatic.

Packing System: Manual or Automatic.

(3)Chicken feed equipment in poultry chicken broiler complete feed pellet line

①Cleaning Machine

To ensure GMP cleaning is an important aspect. Different type of cleaner used for this purpose.

②Conveying machine

All transportations like bucket elevator, screw & chain conveyor etc. for conveying RM & Finished goods.

③Grinding machine

Raw materials need to be grinded as 225 m/microne perticle size by corn milling machine to prepare chicken feed for different type of feed.

④Mixing machine

Different R/M are mixed here with additives, oil/fat, medicines, etc. Good food mixer machine for chicken feed ensure good quality.

⑤Pelleting machine

Produce final chicken pellet feed. A good pellet means "A complete feed" and a good ring die poultry chicken pellet feed making machine can ensure that.

⑥Cooling machine

Extruded feeds are about 70-90° C. Chicken feed cooling machine bring down it at normal temperature (+4° max).

⑦Screening machine

To ensure supply of quality and perfect size feed, screener plays a vital role. Uneven sizes screaned-out.

⑧Bagging machine

Ready chicken pellet feed need to be packed. It can be manual or automatic bagging depends on requirement.

4.Guidance for Operating Large Scale Poultry Chicken Feed Pellet Processing Line With 20 Tons Per Hour

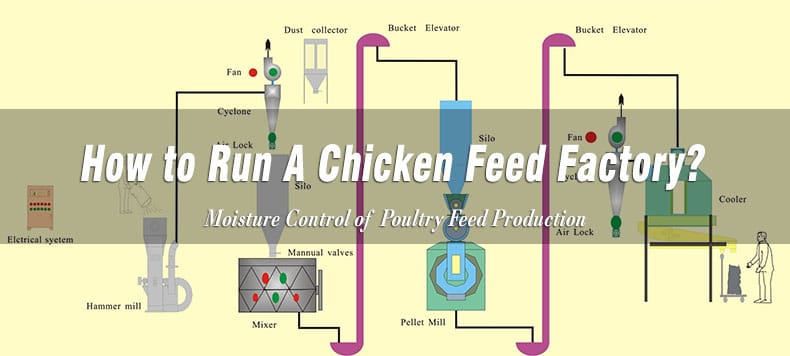

Moisture content is essential in the process of chicken feed line as it is required for intermolecular forces development. The optimal moisture level needed to increase the durability of the chicken feed pellets is between 6% and 12%. The various stages of the pelleting process affected by the water content include: grinding, mixing, conditioning, pellets making and pellets cooling.

(1)Stages of the complete large 20t/h capacity chicken feed manufacturing process

①Chicken Feed Grinding Process

This animal feed crushing process is vital for the chicken feed processing. During this process, the water content decreases. The analysis of the amount of moisture before and after grinding is done by screening the mill with different sieve sizes. The water loss increases with the increase in grain size of the material. The highest moisture loss for various fodder materials is 1%.

②Chicken Feed Mixing Process

If the moisture content of the mixed feed powder is lower than 12.5%, consider adding atomized water when mixing. The amount of this atomized water should not exceed 2%. At this stage of poultry feed production line, the water retention rate is low,and hence of the added 2%, only 40%-50% of it is retained. lt’s recommended to use hot water to prevent theformation of mildew. Add an anti-mildew agent to avoid it. Adjust the nozzle position as well as the nozzle size to ensure uniformity. Adding too much water will increase the risk of mold growth.

③Chicken Feed Conditioning Process

The moisture, temperature as well as time are the factors that control the quality of the conditioning of the feed materials. During steam conditioning, the amount of the mixed water affects the temperature of the conditioning due to the heat energy supplied by the steam. The conditioning can be controlled by adjustment of both the amount of steam as well as the time taken for conditioning which can be done through changing of the filling coefficient of the chicken feed material in the tuner.

④Feed Pellets Making Process

The pore diameter sizes of the ring dies are different as is the production of pelleted feed products (ring die chicken feed pelleting machine for sale). When making feed pellets for small chicks, ring die with a smaller pore diameter is used to produce feed pellets of smaller size. For smaller grain sizes the amount of water lost while cooling is higher than in larger grains. Hence larger grains have more moisture content than small ones.

⑤Pellets cooling process

It is the last process of chicken feed line. Ensure that the water is below the quality control index. The temperature should be at the proper range where it is not too high. The water content and temperature are related. When the temperature increases (or drops) by 10% the moisture content of the chicken feed pellets increases (or decreases) by 0.6%.

(2)Moisture Control during 20T/H Chicken Feed Manufacturing Process

The following Let's talk about how to better control your new build 20 tons per hour full automatic poultry chicken feed making line to make high quality pellet feed, especially how to control the moisture content during the high quality chicken pellet feed production.The water content dynamics make it hard to measure and control the moisture during chicken feed production. For automatic 20tph large scale chicken feed making factory, the most effective way of doing this is by real-time online moisture detection and control as well as the adjustment of the moisture content of the feed product.

For optimal feed quality it is important to control the moisture levels in the feed pellets as per the prescribed limits during the chicken feed production process. If the moisture level in the chicken feed pellets is very high, the feed pellets are likely to become moldy when they are stored before being sold and used. On the other hand, if the moisture level is lower than the prescribed levels, the chicken feed pellet is likely to disintegrate into powder, which cannot be easily consumed, causing quality complaints and wastage of raw material for chicken feed. Hence chicken feed pellet manufacturers have developed a sophisticated method of controlling the moisture levels in the chicken feed pellets during the feed manufacturing process.

There are two main methods of detecting and controlling moisture levels in the 20 tons per hour large capacity chicken feed making process:

①Feedback: The water levels in the chicken pellets are measured after cooling in the feedback control method.

②Feed-foward Control: The moisture levels in the chicken feed pellets are measured before conditioning in the feed forward method.

The moisture levels measured using these methods are then compared with the recommended value, and the moisture levels in the steam and spray from the chicken feed pellet machine are adjusted according so that the water levels in the feed pellet produced remain at the required levels, stipulated by the quality guidelines. It is observed that better moisture levels are obtained using the feed-forward method of water level control compared to the feedback level.

5.Other Tips for Making High Quality Chicken Feed Pellets In Chicken Feed Plant For 20TPH Capacity

If you are planning to start your own chicken feed making business, or running a 20t/h ce high quality chicken poultry feed plant, here are some additional tips for you to help you better control the 20tph poultry automated chicken feed line. You are also welcome to contact Richi machinery if you are interested in getting more details of our 20t/h poultry chicken feed processing plant list of equipment. We can offer customized 20t/h automatic feed manufacturing plant for poultry and complete project report for your reference!

(1)As a large number of raw material are used in chicken feed line, the moisture levels in the pellets vary significantly. After mixing of raw material the water content will vary between 9-14 % and it should be controlled to remain below 13% during the processing. After conditioning, the moisture levels should be regulated at 15 to 16 percent to reduce the powder rate of the chicken feed pellet. Steam and temperature are adjusted during the manufacturing process to regulate the moisture levels in the poultry feed pellet.

(2)To increase the moisture levels in the feed pellet, the conditioning time can be increased, steam pressure reduced or steam that is not saturated can be used for conditioning. For pellets with higher moisture levels than recommended, supersaturated steam at a high pressure should be used. During the cooling process the water levels in the feed are regulated to meet the required standards. For small pellet feeds, the cooling time is lower, and less air is required. However for larger and wetter pellet feeds, the cooling time is more, and a higher air volume is required.

(3)The addition of water during the manufacturing of the chicken feed pellet is controlled with a PLC based system which includes a programmable flow-meter, water pump, solenoid valve and a stainless steel storage tank. So precise measurement and control of moisture levels is required for production of quality chicken feed pellets.

Pellet feed is widely used in the sector of animal husbandry for feeding chicken, duck, cattle, sheep, pig and other kinds of animals. Many factors affect the quality of feed produced in chicken feed line. Such factors include the texture, appearance as well as the water content. However, other technological factors such as pelletizing, modulating as well as cooling also affect the overall chicken pellet feed quality.

The measurement of the water content is essential in the various stages of pellet feed manufacturing process. The moisture content in pellet feed changes continuously during the feed production process and hence is not easy to control when running a chicken feed making line. The moisture is affected by various factors including; crushing, conditioning and other liquid additives.

6.Some typical turn-key poultry chicken feed pellet plant projects:

Afghanistan 10T/H broiler chicken feed making plant

Uzbekistan 15 tons per hour large chicken feed production plant

Ethiopia 5-6T/H chicken poultry feed mill machine

Kenya 5T/H Animal Powder Feed production line

Zimbabwe 3-5tph chicken feed line with its accessory accessories

Colombia 3-4T/H complete chicken feed manufacturing plant