Common energy feed for poultry

The energy feed for poultry is actually food. Each has its own characteristics. It is best to understand and use it together.

When feeding poultry, sometimes the term energy feed is encountered. What kind of feed is this? In fact, they are nothing mysterious, they are all kinds of food that can be seen everywhere around us. The main ingredient they contain is carbohydrates, which can provide energy to poultry. Although they are all grains, they are different in appearance, and they are definitely different in terms of nutrients. In normal times, you can learn more and better match them.

(1) The first type of poultry feed is corn.

Although they look hard, they are actually very digestible. This kind of food contains more energy and little crude fiber. For poultry, it is also delicious to eat. It is a very common poultry feed. Corn is considered by many to be the king of feed, which shows that its usage is huge. Yellow corn in corn is the most popular because it contains carotene, which has a great influence on the growth of poultry, egg production and the shade of yolk color. It's a pity that this kind of food contains less protein, and other things like calcium and phosphorus are not much. It must be fed with other concentrates.

(2) The second feed is sorghum.

When there was nothing to eat before, sorghum was also a very important food, but nowadays, apart from making pancakes, there is basically no need for them to eat. The energy contained in sorghum is similar to corn, but it contains more tannins, which makes its taste a bit astringent. Many poultry do not eat much. If you eat too much, it will make the poultry constipation. A good energy feed. If you want to use them to feed poultry, the dosage must not be too much, about 10%.

(3) The third type of feed is millet

, which is millet before it is hulled. This kind of grain is a good thing. The energy contained in millet is similar to that of corn, but it has more protein content than corn, and its taste is very good. Poultry also like to eat it. The counterpart of millet is rice. In the specific feeding process, the whole grain of rice is generally not fed directly, because it is really impossible to feed it. If you use rice as feed, you can buy broken rice directly. This feed has the same ingredient content as corn and has a better taste. Poultry generally like to eat it.

(4) The fourth type of feed is wheat

, which is similar to millet. It is similar in energy to corn and has more protein content. If you simply feed poultry with whole wheat, the cost is definitely high. In order to save costs, you can use those immature wheat as feed. This immature wheat has two advantages, one is higher protein content, and two It is cheaper.

(5) Barley and oats are also common grains in many places.

These two grains do not contain as much energy as wheat, but they have higher protein content than wheat, but their shells are too hard and need to be crushed. Or it may be fed to poultry after germination.

(6) In addition to food, their processed residues, such as wheat bran and rice bran

, are also good energy feeds, and the price is very cheap, which can reduce the cost of breeding. Wheat bran is a very commonly used poultry feed. It contains more crude protein and is relatively soft. It is very popular with poultry. Its disadvantage is that there is more crude fiber, and diarrhea will occur if you eat too much. Pay attention to the dosage in the usual feeding process. Rice bran is leftover after processing rice. Its energy content is not very high, but it contains a lot of crude protein and crude fiber, but it contains a lot of oil and it is a bit difficult to store.

(7) Sorghum also has processed products called sorghum chaff.

The crude protein content in it is relatively high, the other content is not high, and it contains a lot of tannins, and the taste is not good, so the ratio is very low in the usual feeding process. The feeding of poultry is the same as what people eat. It needs to be diversified, and the ratio should be paid attention to so that these foods can play the best role.

The above-mentioned foods are relatively common. After understanding their content and advantages and disadvantages, they can be more reasonable in the subsequent matching and feeding.

Summary of the disadvantages of feeding poultry chickens with raw food

In rural areas, most farmers use raw grains to feed poultry chickens. Directly using raw grains to feed poultry chickens will damage the nutritional value of raw grains. Of course, there are other shortcomings.

(1) A lot of waste of feed

The raw grain is not processed and ground directly for poultry breeding. Although it is more convenient and cost-effective, it will greatly reduce the utilization rate of feed. Because chickens and ducks have no teeth, they swallow them directly without chewing during the foraging process, and the intestines of chickens and ducks are relatively short, which makes the food eaten by chickens and ducks in their intestines. The residence time is relatively short, only about 4 hours. Such a short time is not enough for chickens and ducks to fully digest and absorb the raw food eaten, so this will directly cause a lot of waste of feed. The foul smell of the feces excreted by chickens and ducks can fully prove that a large number of nutrients in the raw food are not absorbed, but are directly excreted.

(2) Single feed species

During the breeding process, a single raw grain is used to feed poultry. Due to the unity of feed species, the nutritional content of chickens and ducks will be incomplete. If this is the case for a long time, it will seriously affect the growth and development of chickens and ducks. Therefore, in the process of breeding chickens and ducks, it is recommended to process and grind the raw food first, and there should be many varieties, not single, so that the chickens and ducks can fully absorb and utilize the nutrients in the feed and grow healthily and quickly.

(3) The breeding benefit is not high

When using raw food to raise chickens and ducks directly, the digestion level of chickens and ducks is not high, which will easily lead to insufficient nutrition, which will affect the growth and development of chickens. Broilers will slow down their weight gain and affect laying hens. These will directly cause the economic benefits of farmers to decline.

The most suitable feed for poultry compound feed

Compound feed refers to the nutritional needs of animals at different growth stages, different physiological requirements, and different production uses, as well as experiments and research based on the evaluation of feed nutritional value. A certain proportion of feed is evenly mixed and produced according to the prescribed technological process.

-

(1)

The poultry compound feed is designed and produced based on scientific experiments and verified by practice. It concentrates the research results of animal nutrition and feed science, and can evenly mix various components (raw materials) together. So as to ensure the stability and consistency of active ingredients, improve the nutritional value and economic benefits of feed.

-

(2)

The production of compound poultry feed needs to be carried out in accordance with relevant standards, feed regulations and feed management regulations, which is conducive to quality assurance, human and animal health, environmental protection and maintenance of ecological balance.

-

(3)

The compound poultry feed can be fed directly or fed after simple treatment, which is convenient for users to use, convenient for transportation and storage, and reduces user labor.

-

(4)

Feed accounts for 70% of the cost of breeding. The quality and price of poultry feed materials directly affect the quality and cost of compound feed.

-

(5)

In the poultry feed processing and production process, whether it can be formulated to not only meet the nutritional needs and physiological characteristics of animals, but also obtain the lowest formula cost and the best feeding effect, is directly related to the economic benefits and reputation of the enterprise .

-

(6)

The combination of rations is conducive to economic and rational use of various local feed resources and to achieve the greatest social benefits. It helps to give full play to the genetic potential of animals, improve the production efficiency of animals and the economic benefits of enterprises.

How to make animal poultry feed for chicken layer broiler duck goose?

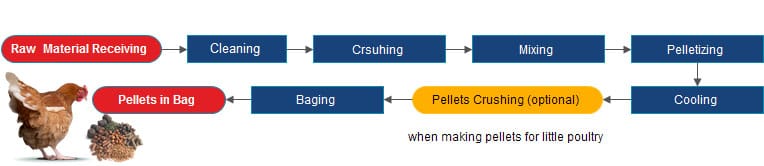

(1)Raw Material Reception and Storage

Poultry feed making raw materials vary, they include: long material like crop straw, grains like wheat, maize, and others like oil cake/meal, additives, etc. different raw materials have different storage methods. For example, in complete poultry feed pellet line of large capacity, storage silo is necessary for storing maize, wheat, and other grains.

(2)Poultry Feed Material Cleaning

The impurities in feed raw materials not only affect the quality of poultry feed pellet products, but also directly relate to the feed processing machines and personal safety. In serious case, the whole equipment can be destroyed, which impacts the smooth progress of the feed production, so the impurities must be removed in time. The cleaning equipment of the feed pellet production line is based on screening and magnetic separation equipment. Screening equipment is used to remove large and long impurities such as stones, mud blocks and sacks. The magnetic separator is mainly used to remove iron impurities.

(3)Poultry Feed Raw Material Crushing

The technological process of poultry feed crushing is determined according to the required fineness and the variety of feed. According to the times of raw material crushing, it can be divided into one stage crushing process, circulation crushing process or two stage crushing process. According to the combination form of batching, it can be divided into first batching, then crushing and first crushing then batching technology. Poultry feed grinding mill is the most commonly used poultry feed machine in this process.

(4)Feed Material Batching/Proportioning Process

At present, the commonly used batching processes include manual batching, volumetric batching, one warehouse one scale batching, etc. Manual batching is mostly utilized in small poultry feed pellet manufacturing plant and medium scale poultry feed pellet factory . In this batching technology, all poultry feed raw materials are weighed manually by workers and poured into the poultry feed mixing machine. As the whole poultry feed manufacturing process like measuring and proportioning is all operated by manpower, it needs less equipment investment and low production cost, and has flexible and precise measuring.

(5)Poultry Feed Mixing Process

There are 2 feed mixing methods: batch mixing and continuous mixing. Batch mixing is to blend all the components together according to the proportion of the poultry feed making formula, and mix them in the periodically running "batch mixer". This mixing method is convenient for replacing feed formula, and the intermixing between each batch is less, so batch mixing is commonly applied at present. However, as the start and stop operation is complex, the automatic program control is mostly used.

The continuous mixing process is a continuous measurement of all kinds of feed components at the same time respectively and proportionately matched to a stream containing various feed components. When the stream enters a continuous mixer, it is mixed continuously into a uniform flow of material. The advantage of this process is that it can be carried out continuously, easily with comminution and granulation, so the production does not need to operate frequently. but when changing feed formula, the adjustment of the flow is more troublesome and the material residue in the continuous conveying and continuous mixing equipment is more, so the intermixing problem between the two batches of feed is more serious.

(6)Poultry Feed Pelletizing

In poultry feed processing factory,poultry feed production raw material conditioning (tempering) is necessary, so hot sale ce high quality ring die poultry feed pellet milling machine is usually equipped with a conditioner on the top. The conditioning result directly influences feed pellets quality. The purpose of conditioning is to add water to the poultry feed powder to let it has certain moisture content. After conditioning, the raw material for poultry is distributed evenly between the roller and ring die, so the feed pellets are pressed out through ring die holes, cut and discharged.

(7)Feed Pellets Cooling

As in the process of pelletizing, the feed is input high temperature and humidity steam, and the squezzing process generates great heat, so the feed pellets moisture content can reach 16-18%, and temperature reach 75 ℃-85 ℃. Under this condition, the feed pellets are easily deformed and broken, and would bond and mildew in storage, so it is necessary to use feed pellet cooler to reduce their moisture to below 14% and decrease the temperature to below 8 degrees Celsius.

(8)Feed Pellets Crumbling

For making young poultry feed pellets of small size, crumbling is also necessary. In order to save electricity, increase the output and improve the quality, the feed material is often made into a certain size pellets in order to save electricity, and then broken into required smaller pellet size. But it is not a must for all feed pellets manuracturers.

(9)Sieving (Screening)

In poultry feed pelleting plant, this process is realized by the poultry feed pellet cooler. But in larger capacity medium feed pellet line, if the crumbler is used, the pellet sieving machine is also needed, since it can separate the powder from eligible feed pellets, so that uniform feed pellets can be deliver to later packaging process, and the powder or uneligible feed pellets can go back for reproduction.

(10)Feed Pellets Packaging

Produced poultry feed pellets are weighted and packaged for sale on the market.

Some poultry feed manufacturing process flow charts

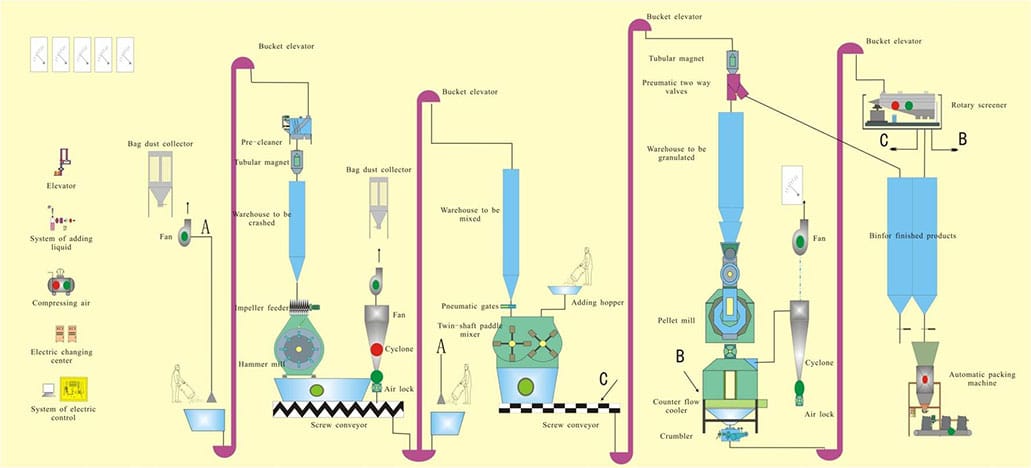

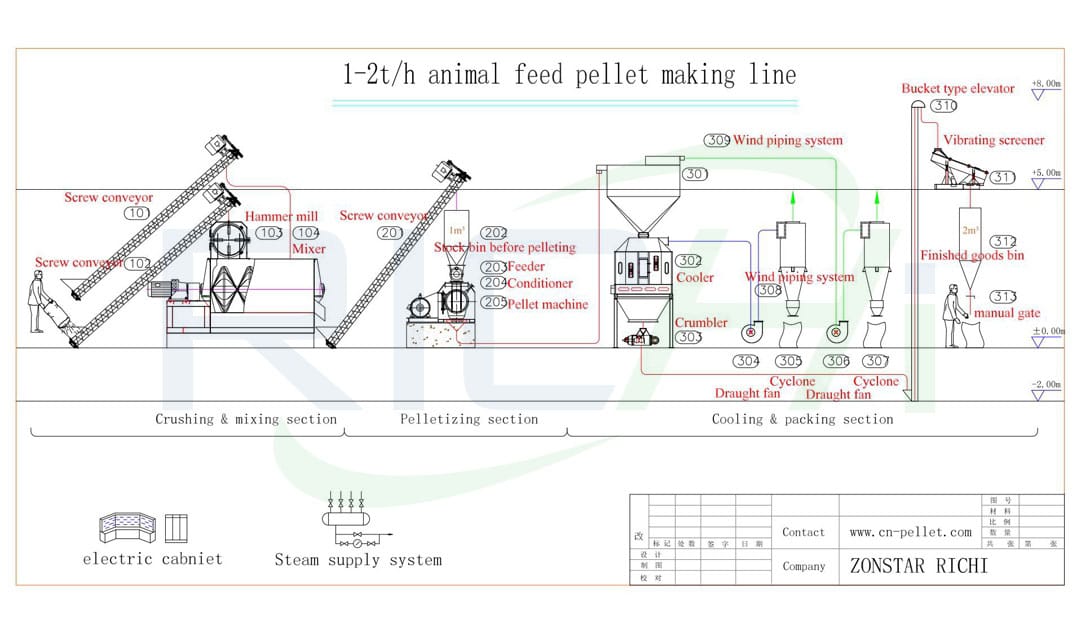

- (1)Complete poultry feed production plant 3-4 ton capacity process flow

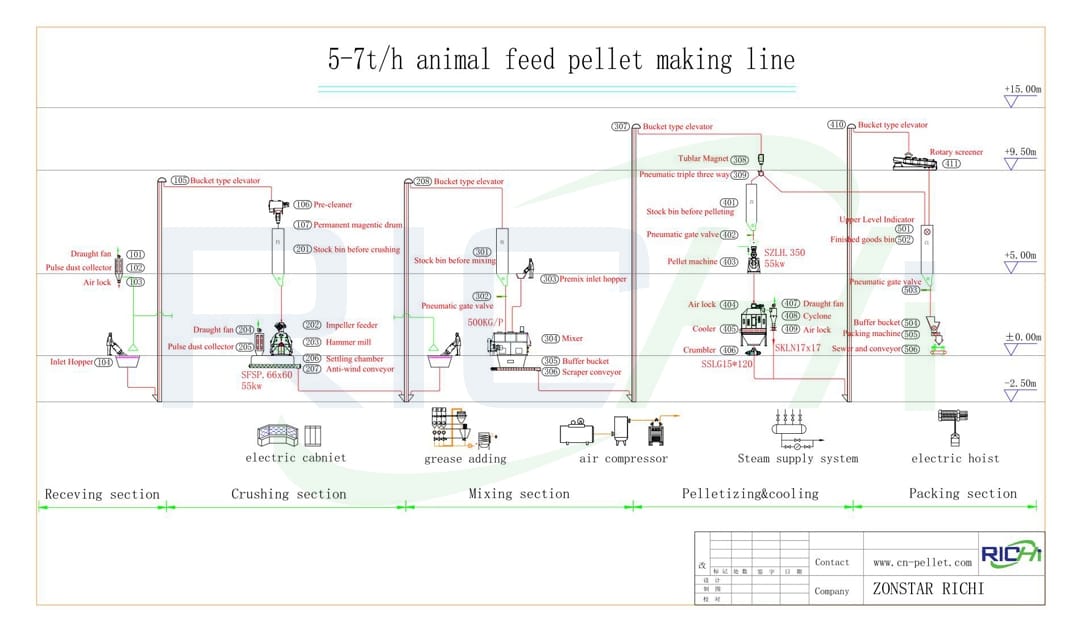

- (2)Complete poultry feed plant 5-7 ton machine atometic flow chart

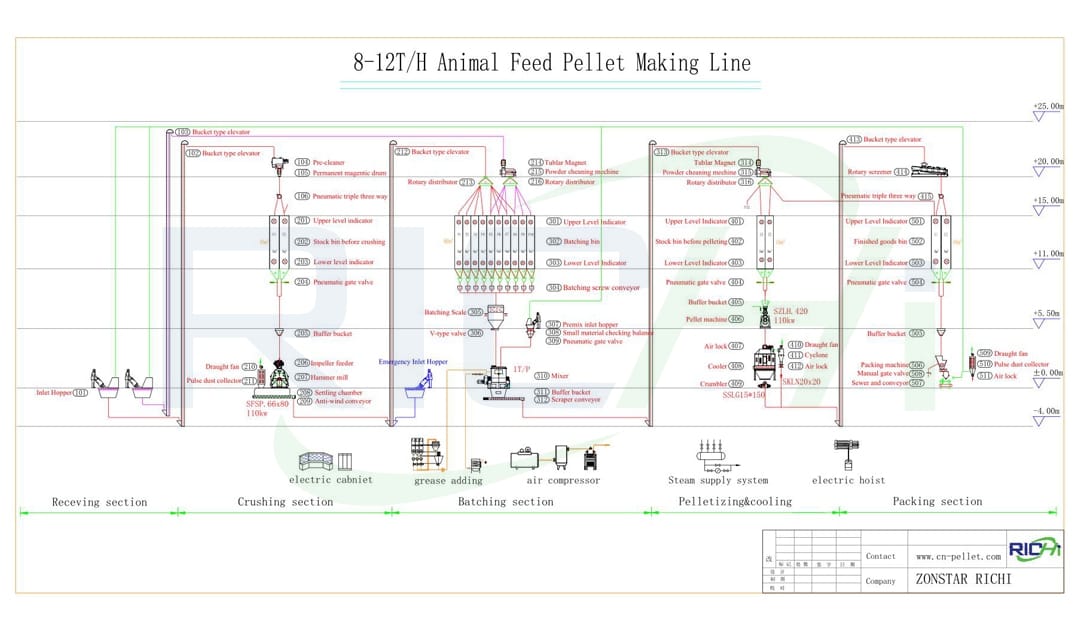

(3)Complete animal and poultry feed processing plant 8-12 ton per hour flow chart

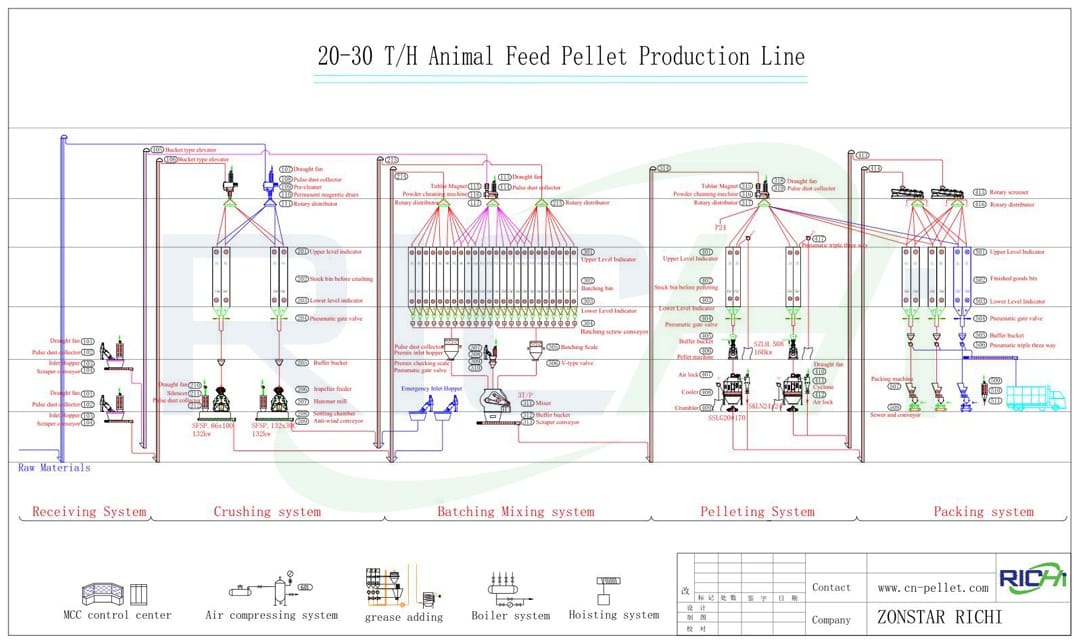

- (4)Complete 20 ton per hour feed manufacturing plant for poultry

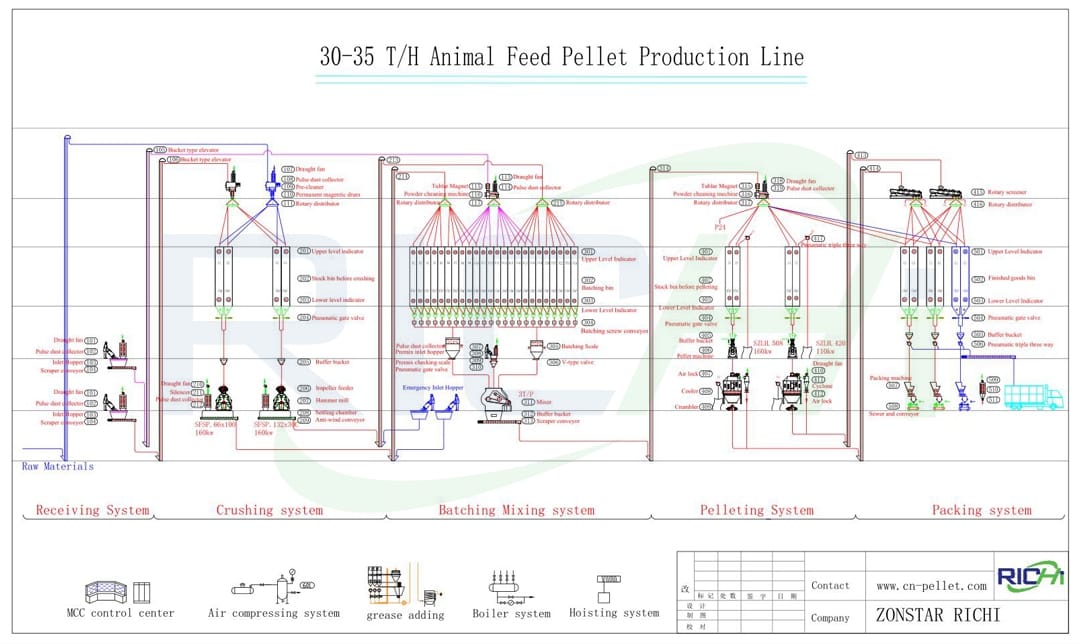

- (5)Complete 30 tons per hour fully automatic poultry feed mill plant flow chart

Poultry feed manufacturing plant cost

- Capacity:1-100 tons per hour.

- Final Product: Pellet feed.

- Pellet Size:2.0-4.0 mm.

- Batching System:Manual or Automatic.

- Packing System: Manual or Automatic.

1-100tph complete animal poultry feed manufacturing plant cost:10000USD-3,000,000USD.