Today we will talk about "5 Ton per hour complete rice husk wood pellet production line for biomass fuel making pellet".Everyone knows that China is a big agricultural country, so China attaches great importance to the treatment of agricultural waste. With the development of biomass energy, more and more agricultural waste has entered our field of vision, including rice husk.

1.Introduction of agriculture waste——rice husk

Rice husks also called rice hulls are the outermost coverings of rice grains. They protect the rice during the growth. They are separated from the rice grains during the milling process. During the milling process, 78 percent of the paddy grain is rice, and 22 percent is the rice husk. The rice husks have 75% volatile organic matter, and the other 25 % is turned into ash known as rice husk ash (RHA). The RHA have 85 – 90 % amorphous silica. The current demand for amorphous silica has pushed its prices over the roof.

Asia is the world leading rice producing continent with nearly 770 million tons annually.As of 2013, China was the leading country with 203.61 million metric tons, second was India with 159.2 million metric tons, third was Indonesia with 71.28, fourth was Bangladesh with 51.5, Fifth was Vietnam with 44.04, and Thailand the sixth with 63.06 million metric tons. Thailand is the largest exporting country. Rice does well in tropical countries because of the availability of water. It is cultivated by flooding the area after seeding. Basmati, Sticky, and Jasmine are the most common types of rice. Rice plants take 3 – 6 months up to maturity, the short duration ones take 105 -120 days while the long duration ones take up to 150 days.

Recently, we have made a pelletizing test of making pellets from rice husks for our customer,so we think it is necessary to talk about some about rice husk pellets manufacturing process and rice husk pellet making machine.

2.How to make rice husk pellets in a 5 ton per hour rice husk wood pellet line?

(1)Hot sale easy operation 5 ton per hour rice husk pellet production line manufacturing process

Rice husks can be made into pellets with the help of different machine. Good quality ce rice husk rotary dryer dries the rice husks in large scale to reduce the moisture content. It is then crushed into powder by rice husk hammer mill. A new design ring die rice husk wood pellet mill machine makes the feeding process easy and fast. It is also good for large quantity production. The rice husk powder is then shaped into even shapes and allowed to cool. Later they are packed with the help of pellet packing material. Rice husk pellets are preferred because of low smoke emission and low amount of ashes. They can be quite convenient in storage and transport and can have multiple purposes.

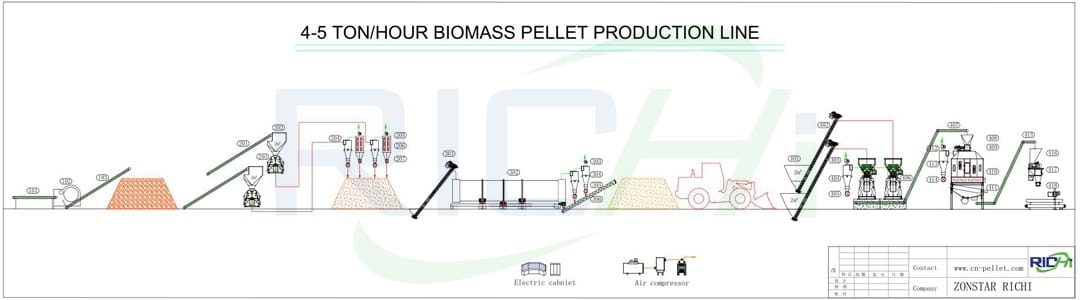

(2)High quality 5tph completely rice husk wood pellet production line flow chart(Can be customized)

(3)Good quality hot selling 5 ton per hour agriculture waste wood pellet line price

Factory supply hot selling 5 ton per hour customized complete rice husk pellet line cost is usually between 200000USD-500000USD.

3.How to choose good quality rice husk pellet mill machine for your 5t/h best solution biomass wood pellet line for rice husk agricultural waste?

The first thing to look at is the quantity of pellet production. A ring die rice husk pellet making machine is recommended for large scale and small scall rice husk pellet production. It is efficient and easy to use. The ring die rice husk pellet press machine that has the warranty, it can return in case of damage. Excellent customer service from the sellers in case of a breakdown or for regular maintenance. It should be a ce good stability rice husk pellet mill that has been widely used meaning it has been tested and proven.

4.RICHI CE Certificate high efficiency ring die rie husk pellet maker series for 5 ton per hour reasonable layout new technology rice husk pellet production line:

800-1000kg/h China professional factory offered ce certificated rice husk wood pellet mill

MZLH320 factory offered hot sale 300-500kg/h biomass wood pellet mill for sale

1-2 ton per hour stable performance rice husk pellet mill machines for sale

ce iso 2-3 ton per hour high performance agriculture waste rice husk biomass pellet mill for sale

2.5-4t/h best price long lifetime rice husk biomass pelletizer for sale

3-4.5t/h China hot sell reasonable design ce rice husk pellet machine for sale

5.Rice Husk Application

Rice husks initially used to be seen as waste product and was discarded away, but with time it has been processed as by products with many uses. It is a very useful commodity. Rice husks can be converted into rice husk pellets and used for animal bedding, as a biomass fuel and in the production of cement.

(1)Rice Husk Pellets As Biomass Fuel

Rice husks are used in rice mills to produce steam for steam engines. It has a high calorie value of 14 MJ/kg. This is equivalent to 35% of diesel oil with a 40.5 MJ/kg caloric value. It can be used for electricity generation, and gasification processes.

(2)Use Of Rice Husk In Animal Keeping

Rice husk is used for animal feeding and bedding for pets. The husk has fewer proteins. It can be treated with 12 % NaOH to reduce silica substance to enhance assimilation. It is used for bedding because it is fire-resistant and does not draw insects. It does not take in feces or urine allowing the animals to remain dry and for easy cleaning. It is soft and comfy unlike sawdust.

(3)Rice Hull As Cement

Burning rice husks in controlled temperatures generates rice husks ash (RHA). RHA contains amorphous silica that is the basic component of the sand which is mixed with cement. Due to its fine nature, it gives a solid concrete. Amorphous silica is ideal in the production of concrete for marine bridges and nuclear plants. the goes deep into cracks in structures sealing it appropriately. The ash has excellent thermal insulation properties.