People who raise chickens know that in the process of raising chickens, in addition to the initial construction cost of the chicken coop, the largest proportion of the cost of raising chickens is feed. Different chicken breeders raise different meat ratios. Profits are very different. Here are 7 kinds of feed-saving measures for everyone. I hope it will help you.

1. Use complete formula feed

Many novices have no special experience in raising chickens. They tend to go down the same path. When raising chickens, they use a single raw material to feed the chickens, for example, they often feed corn. Less, in the end did not make much money, but also lost a lot of feed costs, which is too cost-effective. It is recommended that chicken farmers use complete feed. How to process the complete chicken feed? Some practical chicken feed formulas? That will be told in this article.

2. Feeding high-product breeder chickens

The high or low egg production rate is also related to the breed, especially the farmers who raise chickens. If free-range chickens are mainly egg-laying, we must pay attention to the egg production rate of this breed. At present, the egg production rate of most rural chickens is not high, and many chicken farmers feel that they only need to lay eggs. It does not pay attention to the egg production rate at all, and many of them are more resistant to diseases, but eat more and lay less eggs, which causes a waste of feed.

3. Free-range chickens are worse than cage chickens

Everyone who has raised chickens knows that every time the chickens are fed, the feed is evenly scattered in the trough. When the chickens are eating, they are often piled up in piles. Then the chickens are easy to waste and take a long time to eat. There is a lot of wasted feed. If it is changed to cage, the space for chickens is limited, and the eating is relatively uniform, so there is no waste of feed. For how to save feed in cages, see the next measures.

4. Add sides to the inside of the feed trough

Adding the inside edge of the feed trough is to prevent the chickens from taking out the feed when eating. You can go to the chicken coop to observe whether there is any sprinkled feed on the ground. If so, pay attention to the feed trough. The accumulation of less and more, and a lot of wasted feed over time.

5. Increase feeding frequency

In order to save trouble, some chicken farmers add a lot at a time when feeding. We have observed many chicken farms. The feed pile in the bucket is full. This is not only easy to cause waste of feed, but may also lead to disease. It is recommended that you calculate the approximate feed intake based on the age and number of chickens when feeding chickens, and then feed according to the number of chickens when feeding, less feeding, and keep the feeder empty for about 30 minutes each time to ensure that chickens can eat the feed clean. Don't try to save trouble in raising chickens, save a little effort, and spend a lot of money, it is actually very uneconomical.

6. Don't make the feed moldy

Feed mold is easy to cause the chickens to get sick. The feed is prone to mold during the long-term stacking process, especially in the high temperature and high humidity season. You must pay attention to this point. If the feed is moldy, you can use mold to remove the bacteria. Don't continue to feed the chicken.

7. Reduce feed and eliminate low-yield chickens

For laying hens, the feed should be reduced in time after the peak egg laying period (generally around 42 weeks). Feed reduction should be based on the age and egg production rate. Proper feed reduction does not affect egg production, but also saves a lot of feed costs, and at the same time avoids over-fat chickens. After the peak egg production period, the local chickens should be eliminated in time. In the later period, the local chickens still eat the same ingredients, but the egg production is less. At this time, we eliminated low-yield chickens in a timely manner, and the saved feed was quite a lot.

Regarding the saving of feed costs, there are many methods in the process of raising chickens, but what we have to do is not only to raise the chickens, but also to save the feed costs to the maximum, so that we can raise the chickens and make money. Chicken farmers can make reasonable arrangements according to their own circumstances.

As can be seen from the above, the first way to reduce the cost of feed is the most important. Let's take a look at the relevant knowledge of full-price compound feed.

(1) How to process chicken complete formula feed?

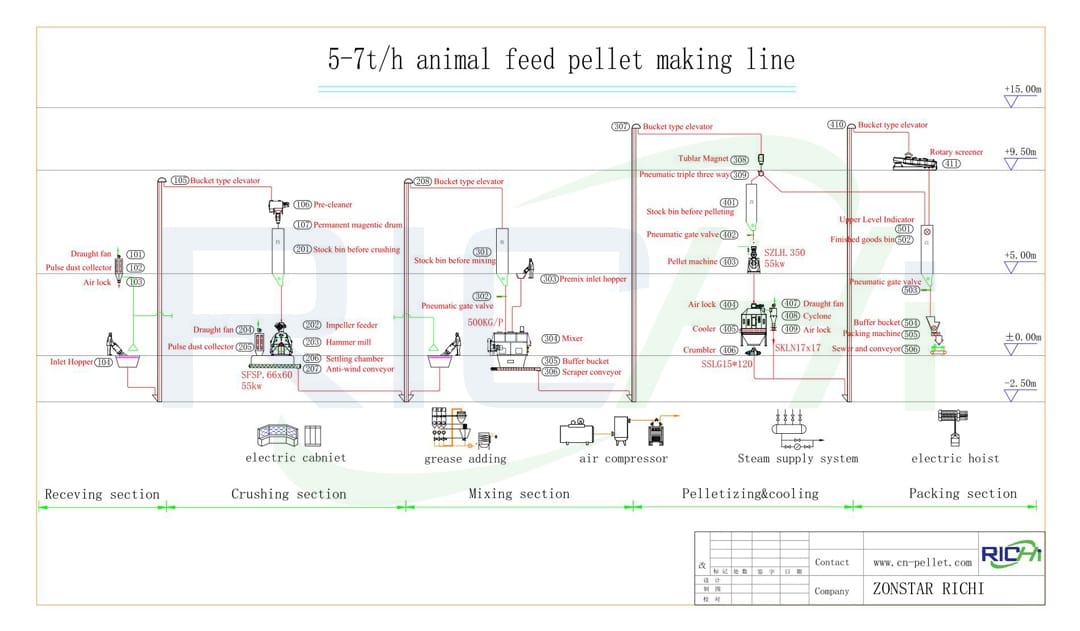

If you want to make chicken mash feed, the manufacturing process of complete poultry chicken feed line: Cleaning → Crushing → Mixing → Packing

If you want to make pellet feed, the manufacturing process of poultry chicken feed pellet process line: Cleaning → Crushing → Mixing → Pelleting → Cooling → Packing

(2) Recommended feed formula for several chickens

a. 60-day-old chicks (0–4 weeks)

| Ingredient | Percentage |

|---|---|

| Corn | 32% |

| Wheat | 35% |

| Bean cake | 18% |

| Fish meal | 12% |

| Bone meal | 1.5% |

| Auxin | 1.3% |

| Table salt | 0.2% |

| Multidimensional element | 0.02% |

Metabolic energy: 12.49 MJ/kg, Crude protein: 22.4%

b. 60-day-old chicks (5–8 weeks)

| Ingredient | Percentage |

|---|---|

| Corn | 58% |

| Wheat | 13% |

| Bean cake | 14% |

| Fish meal | 12% |

| Bone meal | 1.8% |

| Auxin | 1% |

| Table salt | 0.2% |

| Multidimensional element | 0.02% |

Metabolic energy: 12.8 MJ/kg, Crude protein: 20.17%

c. Broilers (0–4 weeks)

| Ingredient | Percentage |

|---|---|

| Corn | 46.7% |

| Broken rice | 7% |

| Wheat | 10% |

| Bean cake | 11.7% |

| Peanut bran | 8% |

| Fish meal | 14% |

| Grass meal | 2% |

| Shell meal | 0.3% |

| Table salt | 0.3% |

Metabolic energy: 12.217 MJ/kg, Crude protein: 21%

d. Broilers (over 4 weeks)

| Ingredient | Percentage |

|---|---|

| Corn | 47.7% |

| Broken rice | 10% |

| Wheat | 9.5% |

| Rice | 4% |

| Bean cake | 7% |

| Peanut bran | 8% |

| Fish meal | 11% |

| Grass meal | 2% |

| Shell powder | 0.5% |

| Table salt | 0.3% |

Metabolic energy: 12.217 MJ/kg, Crude protein: 18.1%

e. Laying hens (0–6 weeks)

| Ingredient | Percentage |

|---|---|

| Yellow corn | 61% |

| Wheat bran | 5% |

| Bean cake | 15% |

| Peanut bran | 8% |

| Fish meal | 8% |

| Shell meal | 2% |

| Dicalcium phosphate | 1% |

| Table salt | 0.4% |

| Methionine | 0.05% |

| Multidimensional element | 0.02% |

Metabolic energy: 12.12 MJ/kg, Crude protein: 19.65%

f. Laying hens (7–10 weeks)

| Ingredient | Percentage |

|---|---|

| Yellow corn | 61% |

| Wheat bran | 10% |

| Bean cake | 11% |

| Peanut bran | 8% |

| Fish meal | 2% |

| Shell meal | 3% |

| Grass powder | 5% |

| Table salt | 0.4% |

| Methionine | 0.05% |

| Lysine | 0.03% |

| Multidimensional element | 0.01% |

Metabolic energy: 11.37 MJ/kg, Crude protein: 15.03%

g. Laying hens (egg production rate 65–80%)

| Ingredient | Percentage |

|---|---|

| Yellow corn | 61% |

| Wheat bran | 5% |

| Bean cake | 11% |

| Peanut bran | 8% |

| Fish meal | 6% |

| Shell meal | 8% |

| Dicalcium phosphate | 1% |

| Table salt | 0.4% |

| Methionine | 0.05% |

| Multidimensional element | 0.02% |

Metabolic energy: 11.5 MJ/kg, Crude protein: 16.8%