Solid organic waste includes food residues, vegetable roots, vegetable leaves, animal hoofs, horns, melon peels, fruit scraps, eggshells, fish scales, eggshells, hair, plant branches, leaves, weeds, animal carcasses, livestock manure, etc.

Made from compressed organic matter, pellets are bio fuels; they can be created by recycling biomass residues, everyday life and garden wastes, agriculture garbage, and virgin lumber. One of the most common types of pellet fuel is generated from combustible garbage,municipal solid waste. Garbage and landfills have caused ground and water pollution, soil and air pollution, this problem of increased environmental pollution is not only harmful for man but animals as well as marine life is also highly disturbed by these waste products. Recycling of municipal solid waste not only cleans up the environment but also saves the new resources use.

1.Turn Rubbish Into Pellet Treasures

Other than that this recycling cleans the environment from such waste that cannot be decomposed thus saving the environment from the horrific threat of global warming. The most popular utilization of garbage and waste is as a fuel source by using biomass fuel pellet machines. These machines are used to make pellets from combustible garbage and solid organic waste, the ce high quality biomass energy pellet machines are environmentally responsible, provide consistent availability of reliable and good quality by product. The ring die biofuel pellet machine works with some steps for converting combustible garbage into recycled pellets. The steps include Picking up of large size garbage from the dumps.

Garbage/Rubbish/Solid Organic Waste Pellet Prodction Process:

(1)Picking up of large size garbage from the dumps

①Combustible garbage conveying;

②Breaking down of garbage bags;

③Waste classification in an air separating system;

④Sorting out material made up of metal;

⑤Electromagneticseparation;

⑥Cleaning and deodorizing.

(2)Garbage waste pelletizing solution

For making garbage fuel pellets from this processed solid waste, the combustible inorganic materials are transferred to the industrial biomass dryer machine, after that are placed into waste fine grinding machine and then this fine powdered material can be made into fuel pellets directly in the biomass waste pellet mill. These pellets are then used in pellet stoves, central heating furnaces, and other heating machines.

2.Main Pellet Machinery For Biomass Waste Fuel Pellet Production

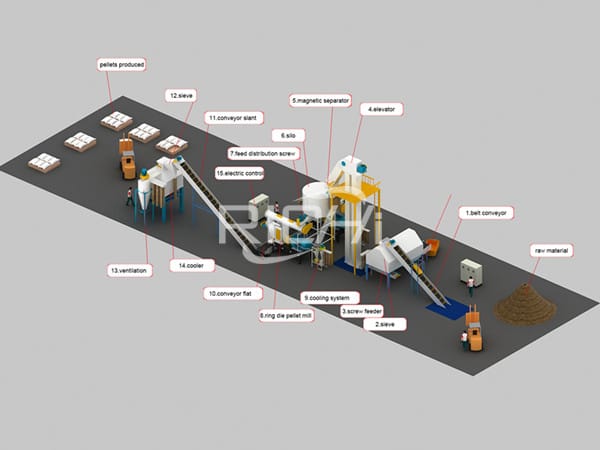

If you are planning to build a turnkey biomass waste fuel pellet making plant, you might need to know about the following biomass pellet processing machienry for industrial pellet production.

②Rotary Dryer Machine for Drying Sawdust

③Good bio-fule pellet machine with ce

⑥Auxiliary equipment

With the increase in price of fossil fuels, the demand for pellet heating has increased, pellet production has increased and doubled between 2006 and 2010. For quality pellet recycling, relay on our machines. Our machines not only recycle waste materials like plastic polyester etc but it also recycles cow dung into pellets other than that delicate materials like crop stalks, sunflower husk and wasted straw can also be converted into pellets by our machines, we aim in creating high quality pellets.

With proper use and proper maintenance the bio fuel rubbish pellet machine can bring about significant economic success to enterprises, our machines save on energy costs and are devoted to give you good and lasting product which you can easily rely upon.

This useful fuel can easily be produced by recycling combustible garbage by our biomass pelletizing machines thus cleaning up the environment as well as increasing awareness of environmental protection. Our solid waste pelletizing system not only reduces labor intensity, saves time and energy, economically beneficial, easier in reach and reliable but also provides you with a material that is cheap and so much in demand and so this all in the cost of cleaning up the environment and man's own habitat.

3.Customized biomass fuel pellet making plant from Richi Machinery:

(1)Forestry Waste Pellet Mill Line With CE

(2)Waste Organic Matter Pelletizing Line

(3)Agricultural Waste Pellet Processing Line

(4)Wood Pellet Manufacturing Line

(5)Whole Grass Pellet Production Line

(6)Professional Manufactured Straw Pellet Plant

(7)Palm Shell Pellet Making Line

(8)Bamboo pellet production line

(9)CE high quality beech wood pellet line

(10)Good quality cotton stalk biomass wood pellet line

(11)Reasonable layout new technology tropical wood pellet line

(12)China professional wood pellet line for pine waste

(13)Heavy duty sugar cane bagasses pellet plant with ce

(14)Professional factory directly offered rubber 1-20tph wood pellet production line

(15)Turn-key biomass coconut shell pellet plant

(16)......