Chicken Feed Formulation and Manufacturing Process Explained

In modern poultry breeding and chicken farming, the production of high quality feeds is essential to ensure healthy growth, optimal weight gain and efficient egg production. The formulation and production of chicken feed has changed significantly from manual mixing to a highly automated and precisely controlled process.

Follow RICHI Machinery here to learn more about the chicken feed production process, with a focus on pellet feed production - the most widely used form of feed in commercial poultry feeding. While feed formulation is fundamental, robust equipment and efficient processes are required to achieve consistency, hygiene and nutritional quality.

Whether you're a poultry farmer, feed mill investor or agribusiness owner, understanding equipment, processes, costs, considerations and product benefits, and even feed formulation refinements can help you make informed decisions when planning or upgrading your chicken feed mill.

Overview of the Chicken Feed Manufacturing Process

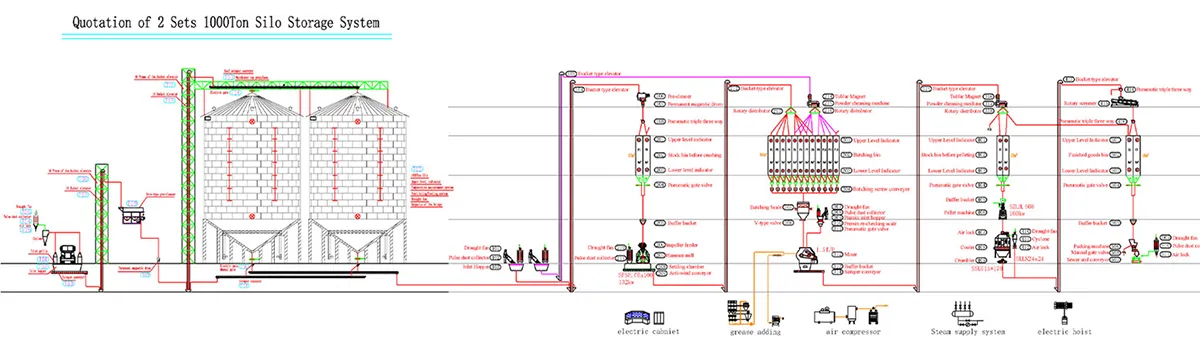

Producing high quality chicken feed pellets requires a systematic, multi-stage process to convert raw materials into uniform, nutritionally balanced pellets. Each step plays a vital role in feed quality, digestibility and production efficiency. Below is a detailed overview of the standard chicken feed production process, but of course in practice, depending on different raw material formulations, different production volumes, different origin restrictions, etc., we will re-customize the most suitable production solution for you.

- Raw Material Receiving and Storage

Equipment: Silo bins, bucket elevator, scraper conveyor, cyclone dust collector.

- Purpose: Ensure stable supply and quality control of all feed ingredients.

- Details:

- Ingredients such as corn, soybean meal, wheat bran, and premixes are delivered in bulk or bags.

- Bulk raw materials are transferred to silo bins or warehouses.

- Moisture content and contaminants (like stones or metals) are checked at this stage.

- Cleaning and Pre-Processing

Equipment: Pre-cleaner, magnetic separator, drum sieve.

- Purpose: Remove impurities that can damage equipment or affect feed quality.

- Details:

- Magnetic separators remove metal debris.

- Vibrating screen separates large impurities like straw or stones.

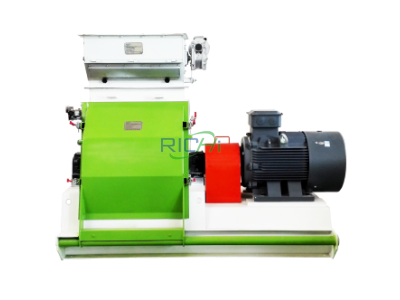

- Crushing (Grinding)

Equipment: Feed hammer mill, feed crushing machine, rotary feeder, air suction system

- Purpose: Reduce particle size for better mixing, digestion, and pelleting.

- Details:

- o Common raw materials like corn and soybean meal are ground to a fine, uniform size.

- o Fineness varies depending on bird age and feed formula (typically 2–4 mm for pellets).

- Batching and Mixing

Automatic batching system, PLC control system, twin-shaft paddle mixer or ribbon mixer.

- Purpose: Combine ingredients according to a precise formulation.

- Details:

- Weighing systems automatically measure each ingredient.

- Thorough mixing ensures homogeneity—key to consistent nutrition and performance.

- Conditioning and Pelleting

Equipment: Steam boiler, conditioner (single or double-layer), chicken feed pellet machine (usually ring die type).

- Purpose: Press mixed feed into dense, uniform pellets.

- Details:

- Steam is injected to soften feed and activate starch gelatinization, improving pellet durability.

- Conditioned feed is compressed through a ring die, forming pellets of 2–5 mm diameter.

- Cooling

Equipment: Counterflow pellet cooler.

- Purpose: Harden pellets and remove excess moisture.

- Details:

- Fresh pellets are hot and soft. Rapid cooling prevents mold and improves storage life.

- Pellets are cooled from ~80–90°C to near room temperature.

- Screening

Equipment: Rotary screener or vibrating classifier.

- Purpose: Remove fines and separate broken or unqualified pellets.

- Details:

- Pellets pass through a vibrating screen to ensure size consistency.

- Fine powder is returned to the pelletizer or reused in the mixer.

- Crumbling (Optional)

Equipment: Feed crumbler (with adjustable rollers).

- Purpose: Reduce pellet size for young birds (especially broiler starter feed).

- Details:

- Large pellets are crushed into smaller particles without generating excessive fines.

- Used when a single pellet die is used for all feed types.

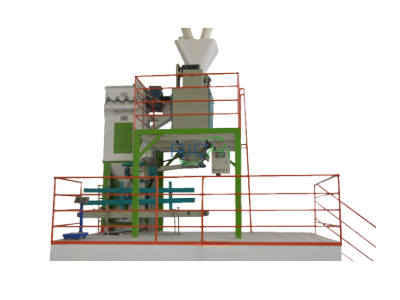

- Packaging and Storage

Equipment: Automatic packing scale, sewing machine, dust removal system, warehouse or silo.

- Purpose: Bag and store finished feed for delivery or use.

- Details:

- Bagged in 20–50 kg sacks or stored in bulk bins.

- Labeled for feed type, production date, and nutritional value.

Process Highlights of RICHI Poultry Feed Production Process

- Full process is typically controlled via a central control system (PLC + HMI).

- Data logging, production reporting, and formula tracking improve quality assurance.

- Optional integrations: fat/oil coating system, molasses mixer, premix micro-dosing, anti-caking systems.

Chicken Feed Production Equipment in Detail

At RICHI MACHINERY, our solution and equipment are of the large commercial type. So we do not support personal and small family farms for now. We provide reliable, durable and energy efficient fully integrated system equipment for large professional poultry farms, commercial chicken feed pellet producers and business investors. The efficiency, quality and safety of chicken feed production depends largely on the performance of the equipment used at each stage.

- Raw Material Handling Equipment

- Main Equipment: Bucket Elevator: Vertical conveying of materials without degradation; Screw Conveyor & Scraper Conveyor: For horizontal material transport; Steel Silos / Storage Bins: Available in different volumes and configurations.

- Key Features: Dust-tight design for cleaner operation; Gentle handling to preserve ingredient quality; Optional level sensors and flow control devices

- Raw Material Cleaning Equipment

- Main Equipment: Drum Pre-cleaner / Vibrating Screener; Permanent Magnetic Separator

- Key Features: Protect downstream equipment (especially hammer mills); Reduce feed contamination risks; Easy to clean and maintain

- Raw Material Grinding Equipment

- Main Equipment: Feed Hammer Mill (with coarse and fine screen options)

- Key Features: High-speed rotor ensures consistent granularity; Adjustable screen mesh size (typically 2–4 mm); Equipped with air circulation or cyclone dust removal system

- Raw Material Batching and Mixing System

- Main Equipment: Automatic Batching Scale (multi-hopper system with PLC); Feed Mixer (double-shaft paddle mixer or ribbon mixer)

- Key Features: ±0.2% batching accuracy; 30–120 second mixing time with ≥95% uniformity; Supports both macro and micro ingredient dosing; Anti-residue design for formula changeover

- Conditioning & Poultry Feed Pelleting System

- Main Equipment: Conditioner (Single or Multi-layer); Ring Die Chicken Feed Pellet Machine; Steam Supply System (Boiler)

- Key Features: Conditioning temperature: 70–90°C for starch gelatinization; Pellet diameter: 2–5 mm (customizable); Siemens motor, SKF bearing, stainless steel conditioner; Wide range of output capacities: 1–30 T/H

- Poultry Feed Pellet Cooling Equipment

- Main Equipment: Counterflow Cooler

- Key Features: Cools pellets from 80–90°C to ≤room temperature +5°C; Preserves pellet structure and hardness; Automatic discharge mechanism to prevent clogging

- Poultry Feed Pellet Screening Equipment

- Main Equipment: Rotary Screener / Vibrating Classifier

- Key Features: Double-layer design for efficient sorting; Recirculation of fines to pelletizing section; Improves final product uniformity

- Poultry Feed Pellet Crumbling Equipment (Optional)

- Main Equipment: Feed Crumbler (roller-type with adjustable gap)

- Key Features: Uniform crumbling with minimal fines; Flexible design for bypassing when not in use

- Poultry Feed Pellet Packaging Equipment

- Main Equipment: Automatic Packing Scale; Bag Sewing Machine / Heat Sealer; Dust Removal System

- Key Features: Bag weights: 20–50 kg (customizable); Packing speed: 6–12 bags/minute (model dependent); Optional bulk bag packing system (500–1000 kg)

- Central Control System for Poultry Feed Pellet Line

- Function: Monitor, manage, and automate the entire production line.

- Main Features: PLC + HMI touch screen interface; Remote formula storage and production tracking; Real-time performance and error monitoring

Characteristics and Advantages of Our Production Process

- Accurate batching ensures nutritional compliance

- High automation reduces manual errors

- Energy-saving motors and steam systems

- Integrated control panels for real-time monitoring

- Easy cleaning and maintenance design

- Modular design: scalable and customizable

Production Capacities & Layout Customization for Chicken Feed Mill

RICHI offers a full range of chicken feed production lines tailored to different scales of operation—from small commercial farms to industrial-scale feed mills. Whether you're producing 1 ton per hour or 30 tons per hour, we provide complete solutions that include not only core equipment, but also smart layout planning, utility integration, and future expansion capability.

Our standard production capacities include 1-2T/H, 3-5T/H, 8-12T/H, 15-20T/H, and up to 30T/H and beyond. Each capacity level is supported by a full set of matched equipment, optimized for both efficiency and footprint. For example, a 5T/H line can typically be installed in a 600–800 m² workshop, while a 20T/H system may require a multi-floor layout to accommodate silo storage, batching towers, and automated packaging zones.

All plant layouts are custom-designed based on the customer’s site conditions, raw material type, product range, and level of automation required. Modular system design allows for phased upgrades and future scaling without major structural changes. We also offer flexible configurations such as single-line, double-line, or split-type production to meet specific process requirements.

In addition, RICHI provides detailed layout drawings, 3D factory simulations, utility planning (steam, air, electrical), and installation schematics—ensuring fast project delivery and smooth on-site setup. Whether you’re starting from scratch or expanding an existing facility, our solutions are built to deliver long-term efficiency and operational excellence.

Investment Cost and Equipment Price Range for Chicken Feed Pellet Production

1-2 T/H Chicken Feed Pellet Production Line

- Production Capacity: 1-2 T/H

- Estimated Equipment Cost (USD): $30,000 – $60,000

- Configuration Scope: Basic semi-automatic system

- Chickens Supported per Day: 60,000 – 80,000

- Notes: Suitable for small farms or new entrants

3-4 T/H Chicken Feed Pellet Production Line

- Production Capacity: 3-4 T/H

- Estimated Equipment Cost (USD): $60,000 – $200,000

- Configuration Scope: Fully automatic batching, pelleting, and packaging

- Chickens Supported per Day: 120,000 – 200,000

- Notes: Ideal for mid-sized commercial producers

8-10 T/H Chicken Feed Pellet Production Line

- Production Capacity: 8-10 T/H

- Estimated Equipment Cost (USD): $150,000 – $300,000

- Configuration Scope: Turnkey plant with full automation and dust control

- Chickens Supported per Day: 320,000 – 480,000

- Notes: Supports multi-formula production

13-18 T/H Chicken Feed Pellet Production Line

- Production Capacity: 13-18 T/H

- Estimated Equipment Cost (USD): $200,000 – $400,000

- Configuration Scope: Advanced system with silo storage, bulk intake, high-speed packaging

- Chickens Supported per Day: 600,000 – 800,000

- Notes: Designed for integrated poultry operations

20-30 T/H Chicken Feed Pellet Production Line

- Production Capacity: 20-30 T/H

- Estimated Equipment Cost (USD): $400,000 – $700,000

- Configuration Scope: Custom-engineered solution, high-level automation, smart controls

- Chickens Supported per Day: 1,000,000+

- Notes: Suitable for industrial-scale feed mills

Here's Everything You Wanted to Know About Chicken Feed Formulas

After we understand all the relevant aspects of chicken feed pellet production, even more fundamental, and needing to be at the top of your business list, is formulation (the ratio of various raw materials). Feed formulation is the nutritional foundation of every successful poultry operation. Whether for laying hens, broilers or breeders, a well-balanced chicken feed ensures healthy growth, high feed conversion and economic efficiency. In pellet feed production, formulation not only directly influences nutritional results, but also pellet quality, processing parameters and ingredient handling requirements.

Core Objectives of Chicken Feed Formulation

The goal of chicken feed formulation is to provide birds with the optimal balance of energy, protein, amino acids, vitamins, minerals, and functional additives, while minimizing feed cost. Formulas vary by:

- Bird type (broiler, layer, breeder)

- Growth stage (starter, grower, finisher)

- Production goals (fast growth, high egg yield, feed efficiency)

Well-formulated feed improves feed intake, enhances immunity, and supports overall poultry performance.

Common Raw Materials Used in Chicken Feed

- Energy

- Common Sources: Corn, wheat, broken rice, sorghum

- Function in Feed: Provides calories for growth and activity

- Protein

- Common Sources: Soybean meal, fish meal, cottonseed meal

- Function in Feed: Builds muscle, organs, and supports metabolism

- Fiber

- Common Sources: Rice bran, wheat bran, alfalfa meal

- Function in Feed: Aids digestion and gut health

- Minerals

- Common Sources: Limestone, dicalcium phosphate, salt

- Function in Feed: Supports bone development and metabolism

- Vitamins/Additives

- Common Sources: Premix, enzymes, probiotics, coccidiostats

- Function in Feed: Complements nutrition and improves health

- Fats/Oils

- Common Sources: Soybean oil, animal fat

- Function in Feed: Increases energy density and palatability

Note: Raw material selection depends on availability, cost, local regulations, and nutritional value.

Nutrient Standards by Chicken Type

- Broiler Starter

- Crude Protein (%): 20–22%

- Energy (kcal/kg ME): 3000–3100

- Calcium (%): 0.9–1.0%

- Use Case: Chicks (0–3 weeks)

- Broiler Grower

- Crude Protein (%): 18–20%

- Energy (kcal/kg ME): 3100–3200

- Calcium (%): 0.8–0.9%

- Use Case: Mid-growth (3–6 weeks)

- Broiler Finisher

- Crude Protein (%): 16–18%

- Energy (kcal/kg ME): 3200–3300

- Calcium (%): 0.7–0.8%

- Use Case: Final fattening stage (>6 weeks)

- Layer Feed

- Crude Protein (%): 16–18%

- Energy (kcal/kg ME): 2700–2800

- Calcium (%): 3.5–4.0%

- Use Case: Laying hens from 18 weeks onward

How Formulation Affects the Manufacturing Process

- Grinding Size: High-fiber formulas may require finer grinding to maintain pellet quality.

- Conditioning Temperature: Starch-rich feeds benefit from higher steam conditioning for better gelatinization.

- Pellet Die Selection: Oil content and ingredient density influence pellet hardness and die specifications.

- Dust & Fines Control: Formulations with bran or dry minerals may require better screening and coating systems.

This close relationship between formulation and processing highlights the importance of integrated planning between nutritionists and production engineers.

Feed Formulation Tools and Services

Most commercial feed mills use feed formulation software (such as Bestmix, Brill, or customized Excel models) to:

- Balance nutrients precisely against cost

- Simulate formula changes based on market prices

- Ensure compliance with nutritional standards

At RICHI Machinery, when you decide to choose us as your poultry feed production solution developer and equipment provider, we will provide you with comprehensive feed formulation support services, including basic formula optimization, ingredient handling recommendations and process matching to ensure that your plant performs optimally with local raw materials.