1–20TPH Local Chicken Feed Formulation Machines — Prices, Features & Complete Processing Guide

1–20TPH China Local Chicken Feed Formulation Machines Prices

- 1–2 TPH: US$7,000–10,000

- 3–4 TPH: US$16,000–20,000

- 5–7 TPH: US$22,000–30,000

- 8–12 TPH: US$31,000–40,000

- 15–20 TPH: US$44,000–50,000

Key Features of SZLH Local Chicken Feed Pelletizers

- High-efficiency gear direct-drive.

- Full stainless-steel feeder with variable-pitch, anti-bridging design; VFD (converter) control.

- Stainless-steel conditioner with axial steam injection for longer conditioning & better cooking.

- Carbonizing & quenching on main gear/pinion for smooth, low-noise running & long life.

- Precision gearbox & housings by specialized casting + NCC machining.

Principles of Local Chicken Feed Formula

Goal: meet nutrient requirements (by stage) at the lowest cost for maximum meat/egg output. Avoid single-feed practices; balance energy, protein, minerals, vitamins and additives.

- Follow standards, flexibly: adjust for breed, age, climate, management, raw materials; verify with small feeding tests.

- Economics first: prioritize nutrient-dense, low-cost, local ingredients (e.g., sweet potato/pumpkin to partly replace cereals when appropriate).

- Palatability & quality: no moldy/pungent/toxic raw materials; avoid too-fine powder; prefer pelletizing to reduce pickiness.

- Diversity: more ingredient types → better nutrient complementation & utilization.

- Stability: change rations gradually (≈1 week transition), especially for layers.

- Inbound QC: test every batch (nutrients, authenticity); trial revised formulas 2 weeks before large-scale use.

- Storage care: control temperature/humidity/ventilation; rodent/water/fire protection; use within 2–4 weeks; mix premixes right before feeding.

Common Proportions (Local Chicken Feed Raw Materials)

- Energy: Corn 40–60%, Wheat 5–10%, Broken rice 5–10%, Bran 5–15%, Oil 1–2%

- Protein: Soybean meal 15–20%, Rapeseed meal 2–5% (not for breeders), Cottonseed meal 2–4% (not for breeders), Peanut meal 5–10%, Fish meal 1–2% (chick stage)

- Minerals: Stone powder 1–1.5% (grower) / 7–8% (layer), Dicalcium phosphate or bone meal 1–1.5%, Salt 0.3–0.4%

- Additives: Trace elements 0.2–0.5%, Vitamins 200–400 g/T, Methionine 0.1–0.2%, Lysine 0.1–0.2%

Sample Formulas

(1) Stage-specific (free-range/local chicken)

| Chicken feed raw material | Brooding (0–6 wks) % | Growth (7–20 wks) % | Laying % |

|---|---|---|---|

| Corn | 63–65 | 60–61 | 64–64.1 |

| Soybean meal | 22–25 | 18–20 | 19–21.5 |

| Bran | — | 5–11.4 | — |

| Bran shorts | — | 4.4–5.4 | — |

| Oil | — | 1 | — |

| Rapeseed meal | 2 | 0–3 | 2–4 |

| Cottonseed meal | 0–2 | 3 | 0 |

| Peanut meal | 2–5 | 4–6 | 4–4.1 |

| Fish meal | 0–2 | — | — |

| Stone meal | 1.2 | 1.2 | 7.6–8 |

| Bone meal | 1.9 | 1.5 | 2 |

| Salt | 0.37 | 0.38 | 0.36 |

| Trace element additives | 0.5 | 0.5 | 0.5 |

| Vitamin additives | 0.03 | 0.02 | 0.04 |

(2) Grazing fattening — supplementary feed

Chickens forage grass/insects/seeds; supplement mainly energy + minerals (and some protein).

| Raw material | Formula A | Formula B | Formula C |

|---|---|---|---|

| Corn | 60 | 61 | 67 |

| Soybean meal | 18 | 18 | 20 |

| Bran | 7 | 5 | 2.5 |

| Bran shorts | 5 | 4 | 0 |

| Peanut meal | 6 | 6 | 7 |

| Oil | 1 | 3 | 0.5 |

| Stone meal | 1.2 | 1.2 | 1.2 |

| Bone meal | 1.0 | 1.0 | 1.0 |

| Salt | 0.3 | 0.3 | 0.3 |

| Trace element additives | 0.5 | 0.5 | 0.5 |

Note: Always align with local regulations, raw material analyses, and stage-specific nutrient specs. Trial new formulas on a small group before scale-up.

Processing of Compound Feed for Native Chicken

(1) Plant & process design

Process should suit varied materials, use compact layouts, advanced/measurable KPIs, safe operation & isolation of dust/noise zones. Large multi-formula plants: adopt automated program control. Small lines: manual metering/ingredients acceptable.

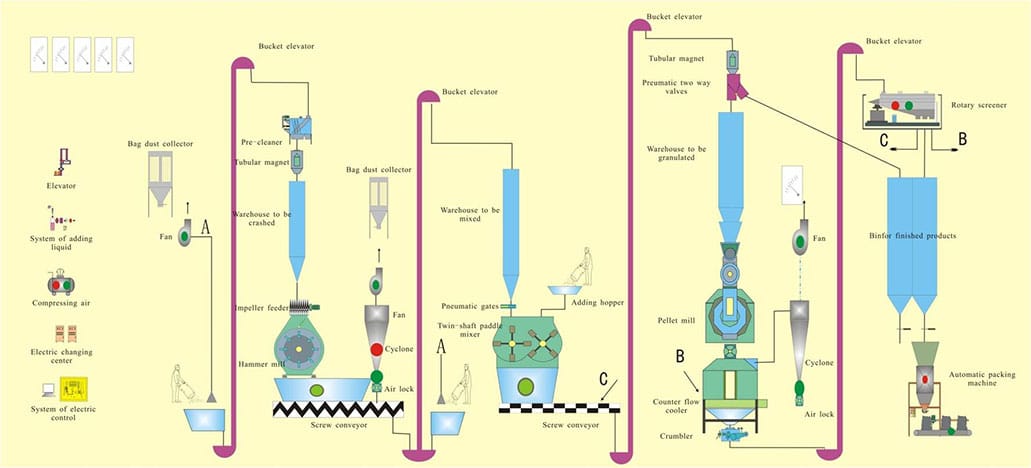

(2) Complete production process

- Raw material storage: typically 15–30 days’ capacity; trend toward bulk handling to cut bag costs.

- Cleaning: remove impurities and ferrous metals for production safety.

- Crushing: target particle sizes per stage/pellet aperture (e.g., <1 mm chicks; ~2 mm grower for Ø4.5 mm pellets; 2–2.5 mm adult for Ø6 mm pellets).

- Batching: accurate dosing (auto weighing/batching recommended).

- Mixing: CV ≤ 10% for uniformity.

- Pelletizing system: crush → batch → mix → steam condition → pellet → cool → screen → pack. Early-stage often pellets via Ø2.5–3.0 mm ring die then post-crush/classify; later-stage typically Ø2.0–3.0 mm with no re-crush.

- Packaging & logistics: 40 kg or 5–10 kg woven bags; stack on pallets; observe shelf-life on labels.

Request a tailored quote or a full line layout

- Website: SZLH series ring-die pelletizers

- Email: enquiry@cn-pellet.com

- WhatsApp/Cell: +86 158 0389 7674