FAQs on pellet making machine, pellet mill, or other related equipment. Common problems when using the pellet machine and how to solve it.

How much does 1 ton of wood pellets cost?The cost of 1 ton wood pellets is mainly determined by the biomass wood raw materials, calorific value, ash content, moisture, packaging, quality, transportation distance, wood pellet production equipment, manufacturer cost and other factors of pellet fuel. The prices are not the same. Today we will systematically analyze wood pellets from multiple angles. The price of pellet fuel, so that everyone can better understand the real price of wood pellet fuel.

Let’s explore the real cost of 1 ton of wood pellets and how the right production equipment can change the game.

The price of 1 ton of wood pellets varies depending on your location, raw material availability, and market demand. In general:

| Region | Average Price (USD/ton) |

|---|---|

| North America | $150 – $250 |

| Europe | $200 – $300 |

| Southeast Asia | $100 – $180 |

These prices typically include raw material, processing, packaging, transport, and profit margins. But what if you want to take control of those costs?

To better understand where your money goes, here’s a basic breakdown of the cost components:

| Component | Estimated Cost (USD/ton) |

|---|---|

| Raw material (e.g. sawdust, chips) | $30 – $60 |

| Electricity & Labor | $20 – $40 |

| Equipment Depreciation | $10 – $25 |

| Packaging | $5 – $10 |

| Transportation | $15 – $30 |

| Total Production Cost | $80 – $160 |

As shown, raw materials and energy are major cost drivers—but production equipment plays a key role in efficiency and long-term savings.

Using professional wood pellet production equipment significantly improves efficiency and output, reducing production costs per ton. Advanced machines also help ensure stable pellet quality and reduce energy consumption.

Key benefits of using the right pellet machinery include lower electricity consumption per ton, higher output with less labor, reduced downtime and maintenance costs, and faster ROI. In short, better machines = lower production costs + higher profits.

Let’s compare the cost of buying vs. producing wood pellets:

| Item | Market Purchase | In-House Production |

|---|---|---|

| Cost per ton | $220 | $120 (avg.) |

| Annual usage (tons) | 2,000 | 2,000 |

| Total annual cost | $440,000 | $240,000 |

| Annual savings | – | $200,000 |

Note: This example assumes a medium-sized production line and average local material cost. Equipment investment can be recovered within 1–2 years.

A complete wood pellet production line typically includes the following:

| Equipment | Function |

|---|---|

| Hammer Mill | Crushing raw materials like logs, branches, or chips into fine powder |

| Dryer | Reducing material moisture to 10-15% (ideal for pelletizing) |

| Pellet Machine | Compressing material into dense wood pellets (flat die or ring die) |

| Cooler | Lowering pellet temperature and hardening pellets for storage |

| Packing Machine | Automatically weighing and packing pellets for sale or storage |

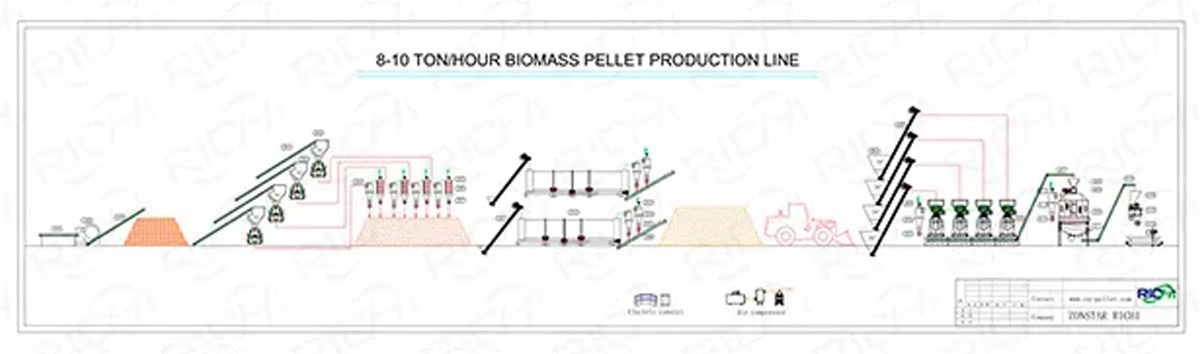

Depending on your capacity, layout, and raw material, RICHI Machinery provides tailored turnkey wood pellet production solutions with capacities from 500 kg/h to 10 tons/h.

Here's an overview of equipment investment for different production capacities:

| Capacity | Equipment Cost (USD) | Suitable for |

|---|---|---|

| 500–800 kg/h | $20,000 – $160,000 | Small businesses/farms |

| 1–2 tons/h | $40,000 – $270,000 | Medium-scale production |

| 3–5 tons/h | $100,000 – $450,000 | Commercial pellet plants |

| 6–10 tons/h | $200,000 – $1,000,000+ | Large-scale factories |

Pro tip: Start small and scale up. Many of our clients begin with a 1–2 ton/hour line and expand based on local demand and biomass availability.

While buying wood pellets may seem more convenient in the short term, long-term profitability and sustainability lie in producing your own pellets—especially if you have access to affordable raw materials like sawdust, wood chips, or agricultural residues.

Investing in a professional wood pellet production line not only lowers your per-ton cost but gives you full control over product quality, supply, and profit margins.

Whether you're a farm owner, a biomass processor, or an energy investor, RICHI Machinery is here to help. We provide:

Customized pellet production solutions

Full-process engineering support

Installation, training, and after-sales service

Contact us today to get a personalized equipment quote and production cost analysis.

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2025

Product Line-Up / Privacy Policy