What is the price for 2 ton per hour capacity dry type floating fish feed pelletizing extruder machine line?The cost to start a 2 ton per hour capacity dry type floating fish feed proceesing line is usually between 130,000USD-190,000USD.

1.Introduction of 2tph high quality floating fish feed extruder machine

The most important equipment in the complete 2 ton per hour floating fish feed pellet production line is the pellet extruder for floating fish. Why is the floating fish extruding feed pelletizer the most important? Because if you want to process fish feed, in order to save costs, you don't need to buy a fish feed grinder machine or a fish feed mixer, but you must buy a fish feed pellet extruder machine.Through the years, interrupted flight extruder type pellet machines have manufactured human foods, animal feeds and adhesives made from cereal grains. Interrupted flight extruders impart cooks that destroy undesired enzymes, such as urease, lipase and myroxinase. These extruder machine transform oilseeds, such as cottonseed and soybean and screw pressed oilseeds, into porous collets that dissolve extract very efficiently. Interrupted flight expanders also dry synthetic rubber by mechanical friction.

The floating fish feed extruder or expander is a kind of floating fish feed pellet making machine. Sometimes, it is used as a pressure conditioner before the floating fish feed pellet mill for improving the pellet properties and nutritive effects. Sometimes, it is also be used as a standalone machine for producing a fish feed product which is fed to the animals directly. The field of application is not limited to the hydrothermal pressure treatment for improving the nutritive value, but the expansion also helps to reduce pathogen germs, inactivate anti-nutritive factors, modify starch, and increase the content of rumen undegraded protein.

The extrusion cooking process, because it causes a high level of gelatinization of starches, results in feeds with good water stability. It can produce "expanded" floating fish feed pellets as well as sinking fish feed pellets. The process also improves the digestibility of the product.

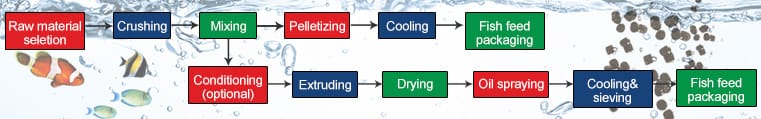

2.Configuration of fish feed machinry for setting up high complete 2tph capacity floating fish food production plant

| Name | Model | QTY | Power(KW) |

| Fish feed grinding machine | SFSP56*40 | 1 | 45 |

| Pulse dust collector | TBLMa.18a | 1 | / |

| Bucket elevator | TDTG36/18 | 1 | 3 |

| Fish feed mixing equipment | SLHY2.5A | 1 | 15 |

| Floating fish food extuder equipment | DGP-200B | 1 | 132+1.5+4 |

| Fish food dying machine | RH-WH2000 | 1 | 45+5.5+2.2 |

| Coating machine | SYPL15C*2 | 1 | 4+0.55+0.09 |

| Cooling machine | SKLN17*17 | 1 | 0.75 |

| Auto-packing machine | DCS-50 | 1 | 2.2 |

| Sewing + belt conveyor | / | 1 | 1.5 |

| Oil adding machine | YZTG100a 1 | 1 | 1.5+1.5 |

| MCC Control Center ;Mimic control panel | / | 1 | / |

3.Turnkey 2 ton per hour floating fish feed making plant project survice for you

We can provide turnkey floating fish food plant project including the following (1)(2)(3)(4). If you need, pls feel free to contact us.

(1)2T/H Dry Type Floating Fish Feed Complete Processing Line Machinery

| Serial number | Iterms Description | Power(KW) |

| 1 | Crushing and mixing system | Around 75.1 |

| 2 | Extruding and drying system | Around 210.34 |

| 3 | Cooling and packing system | Around 26.45 |

| 4 | Oil adding system | Around 6 |

| 5 | Electrical control system | 0 |

(2)Auxiliary Equipment of 2TPH Fish Feed Making Line ( Price in Turnkey price list)

| Obtaining Method | |

| Air compressor and srorage tank(11KW) | Supply by us or supply by buyer |

(3)The Construction of The workshop (Above The Groud)

| Obtaining Method | Supply by us or supply by buyer |

| The main shop C structure steel, stairs in side, and attached parts | Price in Turnkey Project |

(4)Installation Cost

|

Installation and commissioning cost -----To guide the Installation& commissioning; 2 persons -----The meals ,accomodation ,and the flight ticket fee need paid by buyer; -----USD 100/day/person .Because different situation in different country, so the installation cost will be calculated by days. if over plan days, customer need to pay more based on days, if less than plan days, supplier should return salary based on real installation days |

By buyer |