Richi Machinery is a China animal feed mill equipment manufacturer, today,this article will introduce animal feed pellets production in detail.

1.What Is Animal Feed Pellets Production?

Feed pellet means that the feed is crushed by feed hammer mill crusher and pressed into pellet feed of varying diameters by a special compression molding. The ce high quality animal feed pellet making machine produced by Richi Machinery has better performance in the pelletized feed. The raw material composition of the pellet feed can divide into a concentrate feed pellet, a mixture pellet, a coarse pellet, etc. More used are the mixture pellets and the coarse pellets.

The mixed pellets are weighed in proportion to energy feed, bran feed, protein feed, additives, etc., and are thoroughly stirred and mixed uniformly, and then pressed into pellets. The coarse pellets crush the roughage (such as corn mash) into pellets, and the pellets are pressed without the binder. Large pellets (blocky) coarse material (made from hay flour) have unique advantages in pastoral areas, commonly known as beef biscuit feed.

2.Shaped Animal Feed Pellets

The pellet feed refers to a pelletized feed obtained by pressing the processed powdery compound feed through a animal livestock poultry feed production machine. Compared to powder feed, pellet feed has many advantages, summed up in five ways:

(1)It is convenient for storage, packaging, and transportation. After the feed is formed, the pellet feed is reduced by about 1/3 than the powder feed, which is convenient for storage, packaging, and transportation. During storage, the powder feed is easy to absorb moisture and agglomerate, and the pellets are granulated. The feed has good dispersibility, low hygroscopicity, and high storage stability, automatic classification is avoided during the transportation of the finished product, the loss of dust and trace components is reduced during the packaging process.

(2)Sterilization. During the granulation process, certain toxic substances or inhibitors (such as trypsin inhibitor, hemagglutinin, etc.) in the feed are destroyed by heat. At the same time, 90% of Salmonella can be killed.

(3)Improve the palatability of livestock and poultry, increase feed intake due to the high density of pellet feed, volume reduction, high nutrient concentration, so that the animal's feed intake also increased accordingly.

(4)Easy to digest and absorb, improve feed utilization through granulation, improve the physical and chemical properties of certain nutrients in the feed, improve feed utilization, and improve nutrient utilization.

(5)Prevent livestock and poultry picky eaters, reduce feed waste due to the uniform size of the pellet feed, comprehensive nutrition, thus ensuring the integrity and full price of the feed components, avoiding the selection of feed for livestock and poultry according to their palatability. Reducing the air, water loss caused by flying dust everywhere. Moreover, the pellet feed is easy to identify, and the pellet feed size of piglets, growing pigs, and finishing pigs is small to large.

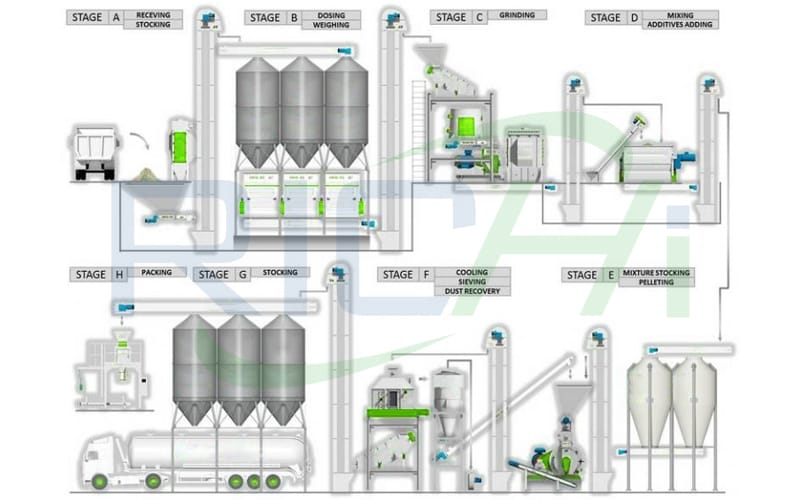

3.Animal feed line manufacturing process

How to start animal feed factory?What is process line of making animal feed pellet?The followings are the latest animal feed processing technology.

In the animal feed pellet production process, under the combined action of water, heat, and pressure, the starch is gelatinized and cracked, and the structure of cellulose and fat is changed, which is beneficial to the full digestion, absorption, and utilization of livestock and poultry, and improves the digestibility of feed. High-temperature sterilization by steam reduces the possibility of feed mold and insects and improves the palatability of the feed.

(1)Raw material receiving: After the raw material is discharged into the receiving pit, it is transported by the conveyor, the bucket elevator, and the screening of the primary cleaning magnetic separator, and then sent to the vertical silo for storage or sent to crush warehouse, ingredient warehouse.

(2)Raw material cleaning: Mainly to remove impurities in raw materials, you can use the primary magnetic separator, which can be easily cleaned.

(3)Feed crushing: The purpose of this is to increase the surface area of the feed so that the animal can digest and absorb it. It can also improve the quality of the feed. Generally, the pellets are pulverized twice., more thorough.

(4)Ingredients: Generally, the multi-storage and the multi-scale batching process are adopted. The batching scale is an electronic batching scale, which can improve the precision of the ingredients and improve production management.

(5)Feed mixing: It is the uniform mixing of the materials to ensure the quality of the feed. At present, most of them are mixed by using a batch horizontal belt mixer.

(6)Liquid addition: It is to add some extra substances in the feed to increase the content of protein, amino acid and vitamin in the feed, usually adding molasses.

(7)Feed forming: When the feed is formed, a ce certificate ring die animal feed pelletizer machine to pelletize animal feed can be used, and the pellet feed from the CE ISO approved animal feed pelleting machine should be cooled. After cooling, if the feed pellets are large, they can be broken into smaller particles. By grading screening, qualified products are extracted, and if they are unqualified, they are re-granulated and granulated.

4.Animal feed production process flowchart

5.Most common machines for animal feed processing

multi crusher machine for animal feed

animal feed pellet making machine with ce

animal feed pellet cooling machine

crumbler machine,etc.

As a professional animal feed mill production machines manufacturer,Richi Machinery not only provides a complete animal feed pelletizing line plant but also provides a single animal feed making machine in each animal feed production process. In order to meet the different capacity needs of customers when produced animal feed pellets.