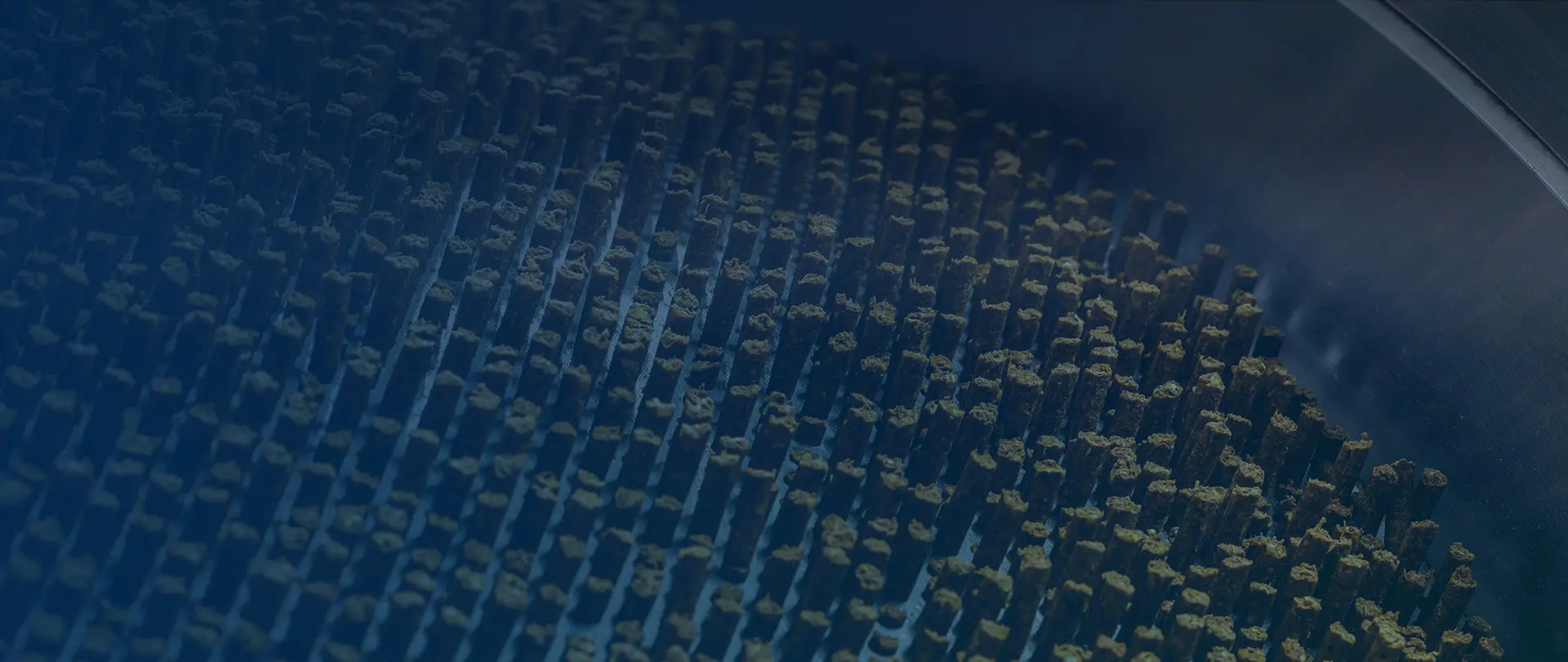

Ensure the longevity and performance of your pelletizing equipment with high-quality accessories such as ring dies, pressure rollers, and screens. Designed to complement and enhance your machines, these durable parts keep your production line running smoothly and efficiently. Boost productivity with reliable, industry-leading accessories.

Learn MoreDepending on your needs, different auxiliary equipment is paired with different pellet production solutions to achieve integrity and continuous rows of pellet production.

Press roller

Ring Die

Main Shaft

Eccentric Shaft

Driving Rim

Alloy Cutting Blade

Sprocket

Solenoid Valve

SJHS Series Rotor

Rotor of Ribbon Mixer

Nozzle

Double Paddle of Mixer

Cylinder

Chain

Wearing Plate

Screen Sheet

Screen Hold-down

Rotor of Grinder

Positioning Block

Pin Shaft

Main Shaft

Hammer

Hammer Knife

Grinding Disc

Grinding Hood

Gear Ring

Grading Pulley

Single-thread for Extruder

Pressure Ring for Extruder

Double-thread for Extruder

Discharging Die

Cutting Blade

Cutter Holder

Extruder Barrel

Roller Shell

Produced with precision engineering and advanced technology for superior performance.

Made from high-grade materials that ensure durability and resilience, even in demanding production environments.

Perfectly designed to integrate with RICHI equipment, ensuring seamless operation and minimizing wear.

Extended lifespan means fewer replacements, reducing downtime and operational costs, while keeping production efficient and uninterrupted.

What kind of pellet plant do you want to establish?

How many tons per hour about this plant you want to build?

Where is this pellet plant going to be built?

When do you plan to start the operation?

Replaceable accessories include critical components that wear out over time due to constant use. These include:

Regular replacement of these parts ensures consistent machine performance and product quality.

The lifespan of dies and rollers varies based on factors such as raw material abrasiveness, machine usage, and maintenance practices. On average:

Frequent inspection for signs of wear, such as reduced pellet quality or output, helps determine when replacement is necessary.

High-quality accessories made from durable materials like hardened steel or carbide offer:

Yes, hammer mill screens are designed to be interchangeable.

Durable dies and rollers are typically made from:

These materials are engineered to withstand high pressure and friction during operation.

Signs that hammers or blades require replacement include:

Regular inspection and replacement ensure optimal grinding performance and prevent damage to other components.

While third-party accessories may fit, there are risks:

It’s recommended to consult your equipment manufacturer before using third-party accessories.

The lifespan depends on:

On average, hammers last between 50-100 hours under heavy operation. Regular inspection helps identify wear and ensures timely replacement.

To choose the right accessories:

Using the right accessories ensures optimal machine performance, efficiency, and longevity.

If you need further information, please contact us

Note: Pellet production is a continuous and complex process, requiring many equipment to complete the production from raw materials to finished pellets. Therefore, it is suitable for commercial projects but not for personal use.

RICHI stick to the service principle is: We are focusing on your future, your future is our future!

© HENAN RICHI MACHINERY CO., LTD 1995-2026