1. Catfish Feed Production Process in Nigeria (Floating & Sinking Pellets)

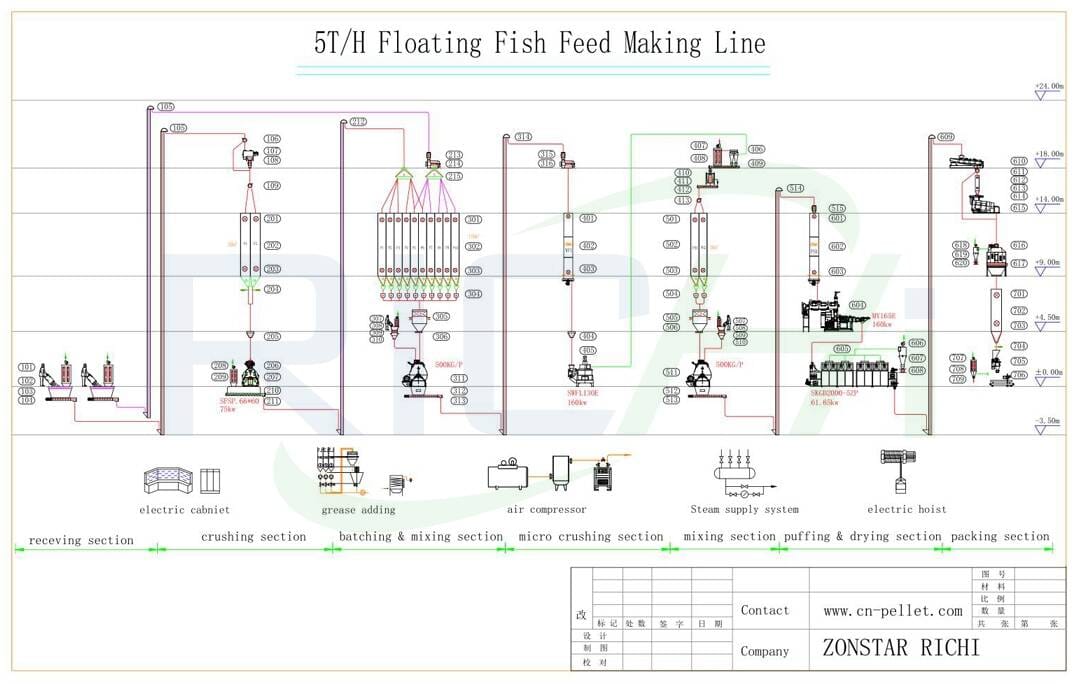

- Floating fish feed production line for catfish processes feed ingredients and additives into nutritionally balanced, water-stable pellets to improve farm profitability.

- Depending on the species and production goals, the catfish feed manufacturing process (sinking pellet line) can range from grinding and particle-size reduction to steam pelleting or extrusion for floating pellets. Catfish feeds must be granular, water-stable, and—often—float.

- Most commercial catfish feeds are extruded. If certain additives are heat-sensitive, use steam pelleting for sinking pellets. Before shipping, post-spray oil/fat to cut fines and improve palatability.

- Grinding section — Reduce ingredients to spec using a catfish feed hammer mill for optimal starch gelatinization and pellet quality.

- Mixing section — Thoroughly blend macro & micro ingredients; options include horizontal fish feed mixers (ribbon, paddle, dual-shaft) with liquid-spray ports for oil, enzymes, or molasses.

- Pelleting/Extruding section — Choose fish feed extruder machines or SZLH series ring-die pelleting machines. Wet-type extruders (with steam) offer higher throughput; dry-type are cost-effective for small scale.

- Pellet drying section — For dry-type extrusion, use a belt dryer to target safe moisture; for wet-type, a gas dryer is recommended.

- Packaging section — Automated weighing & bagging ensures clean presentation, easy transport, and lower labor cost.

2. Prospects for Catfish Farming in Nigeria (Market & Investment Outlook)

- High market demand — Catfish is a key protein source; consistent consumer demand supports steady farm sales.

- Government support — Policies, loans, subsidies, and training help upgrade aquaculture capacity.

- Natural resource advantage — Favorable climate and abundant surface water benefit aquaculture expansion.

- Rising investments — Local and international capital improves efficiency, technology adoption, and yields.

- Export potential — With quality assurance, Nigerian catfish can supply regional and global markets.

3. Introduction to Catfish Feed Pellets (Ingredients & Life-Stage Nutrition)

- Ingredient base — Predominantly plant-based (soybean meal, cottonseed meal, corn & wheat by-products), with fish meal/animal protein in fry diets.

- Processing — Use a fish feed pellet/extruder machine to produce size-specific, floating or slow-sinking pellets matched to fish size and season.

- Hatchery fry — 45–50% protein, finely ground powders/flours.

- Pond fingerlings/juveniles — ~40% protein; some producers use 28–32% for certain growth phases when natural pond food is adequate.

- Advanced/market fish — 28–32% protein floating pellets (≈5/32–3/16"); some switch to slow-sinking feed in winter.

4. Catfish Feed Formula (Sample Rations & Notes)

- Commercial catfish feeds usually follow fixed formulations due to ingredient availability and mill logistics rather than purely least-cost optimization.

- Least-cost formulation requires reliable data on ingredient prices, nutrient specs, requirements, and constraints.

- 40% hay powder, 30% silkworm pupae, 10% vegetable cake, 20% barley — feed coefficient ≈ 3.

- 40% green hay, 30% cotton cake, 10% bean cake, 5% rapeseed cake, 5% silkworm pupae, 5% fish meal, 5% wheat — feed coefficient ≈ 3.

- 47.5% bean cake, 35% fish meal, 1% yeast, 16.5% inorganic salts, etc. — feed coefficient ≈ 2.26.

5. How to Start Catfish Farming in Nigeria (Step-by-Step)

- Machines for making catfish feed — Use catfish feed extruder machines and pelletizers to produce floating or sinking pellets from local, cost-effective raw materials.

- Profitability — Demand outpaces supply; with good management, farms may break even within months.

- Decide farm size — Start small (tanks/ponds) and scale; ensure reliable water supply and environmentally sound siting.

- Feeding strategy — Feed once daily to satiety without harming water quality; twice-daily feeding can increase growth but is often impractical at scale.

- Health & environment — Monitor early disease signs; use approved treatments (e.g., copper sulfate, formalin, hydrogen peroxide, povidone iodine) responsibly.

- Key challenges:

- Capital intensity

- Land acquisition

- Labor requirements

- Technical know-how gaps

- Pest pressure

- Cannibalism among fish

6. What Is the Cost and Profit of Raising an Acre of Catfish?

- Cost & profit example (China) — ~10,000 catties/acre × ¥3/catty ≈ ¥30,000 revenue; costs ≈ ¥10,000 (fry, feed, utilities, labor); profit ≈ ¥20,000 per acre.

- Breeding cycle — Farmed catfish can reach ~2 kg in a year; typical production cycle ≈ 80–90 days, enabling up to two crops/year.

- Breeding environment — Pollution-free site; water temp 18–28 °C, pH ~7.5, dissolved oxygen > 5 mg/L to accelerate growth (>50 kg/m³ possible).

- Pond construction — Example: 80 m × 8 m × 0.6 m flow-through ponds with inlet/outlet and aeration; hatchery loop for fry supply.

- Management — Use formulated feeds or natural prey (trash fish, prawns, zooplankton, algae); prevent fin rot, parasites, and enteritis with sound biosecurity.