Wood pellets and fuel pellets are generally growing rapidly, and even in short supply. Oil and gas prices are high, and excessive use can cause climate change. Pellet fuel is very clean and cheap, and compared to fossil fuel, it is not easy to cause global warming.

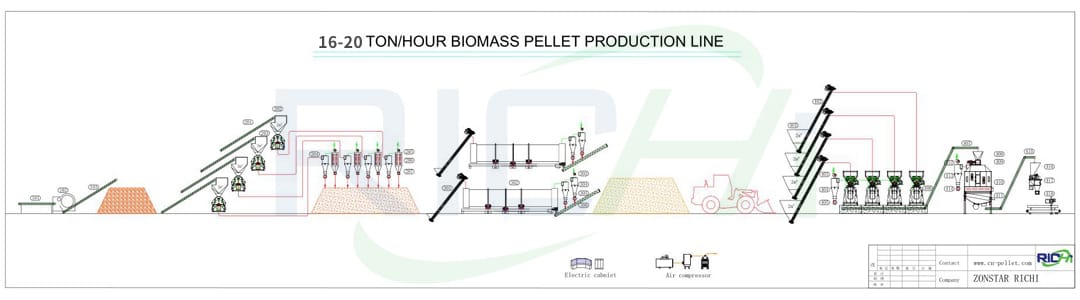

1. Chipping section

Choose wood chip machine according to output and log diameter size, there are drum chip machine and disc chip machine.This section mainly cuts logs from logs within 50cm in diameter into small pieces within 5mm to reduce the difficulty of drying and reduce the power of crushing.

2. Drying section(wood chips sawdust rotary dryer)

Calculate the required evaporation based on the incoming moisture and outgoing moisture, select the diameter of the drum and the model of the hot blast stove.At present, there are commonly used three-cylinder dryers, single-cylinder dryers, airflow dryers, and hot air stoves for fuel oil, gas, coal, and pellets. This section is mainly for drying wood with moisture of 20% -60% to 12-18% for the next step of processing.

3. Crushing section(super quality wood hammer mill for wood sawdust)

Crush the dried wood chips. The company adopts positive and negative pressure combined with discharge and dust removal methods to effectively reduce the wear and dust of the fan, which is the domestic advanced discharge method.This section is mainly to reduce small wood chips to wood chips within 8mm, which is used in the processing of pellet machines.

4. Granulation section(high quality wood pellet machine)

Processing wood chips into granules with diameters of 6mm, 8mm, 10mm and 12mm. It is the core part of the entire production line.Before granulation, iron blocks, stones, etc. need to be sorted out. The company uses the most advanced vertical ring die granulator in the country for granulation, which consumes less energy, wears less, has higher pressure, has a wide range of use, and is sensitive to different materials. Low model.

5. Cooling section

After the pellets are produced, the temperature is 70-90 degrees, and they cannot be packaged immediately. The cooler cools the pellets from 70-90 degrees to room temperature ± 5 degrees for packaging.This section adopts counter-flow air cooling, which has the advantages of good dust removal effect and short cooling time.

6. Screening section

During the cooling and conveying process, the compressed wood chips will generate a small amount of powder after collision, so screening equipment is needed to separate the finished wood pellets.In this section, the vibration grading screen is mainly used to separate the particles of the finished products to meet the packaging requirements.

7. Packaging stage

The compressed finished granules need to be packaged before they are sold to customers, generally bags and tons of bags.This section is packaged according to customer requirements. The company's fully automatic packaging machine has a large packaging volume and low labor consumption, which will greatly reduce packaging costs.